Stainless steel plates are still very common in daily life, and they are also used in daily life. Different stainless steel plates have different sizes and specifications, and there are many sizes. Before choosing, you still need to know something about the size. Only in this way can we know how to buy what size is suitable, the standard size of stainless steel plate? What are the methods of cutting stainless steel plate?

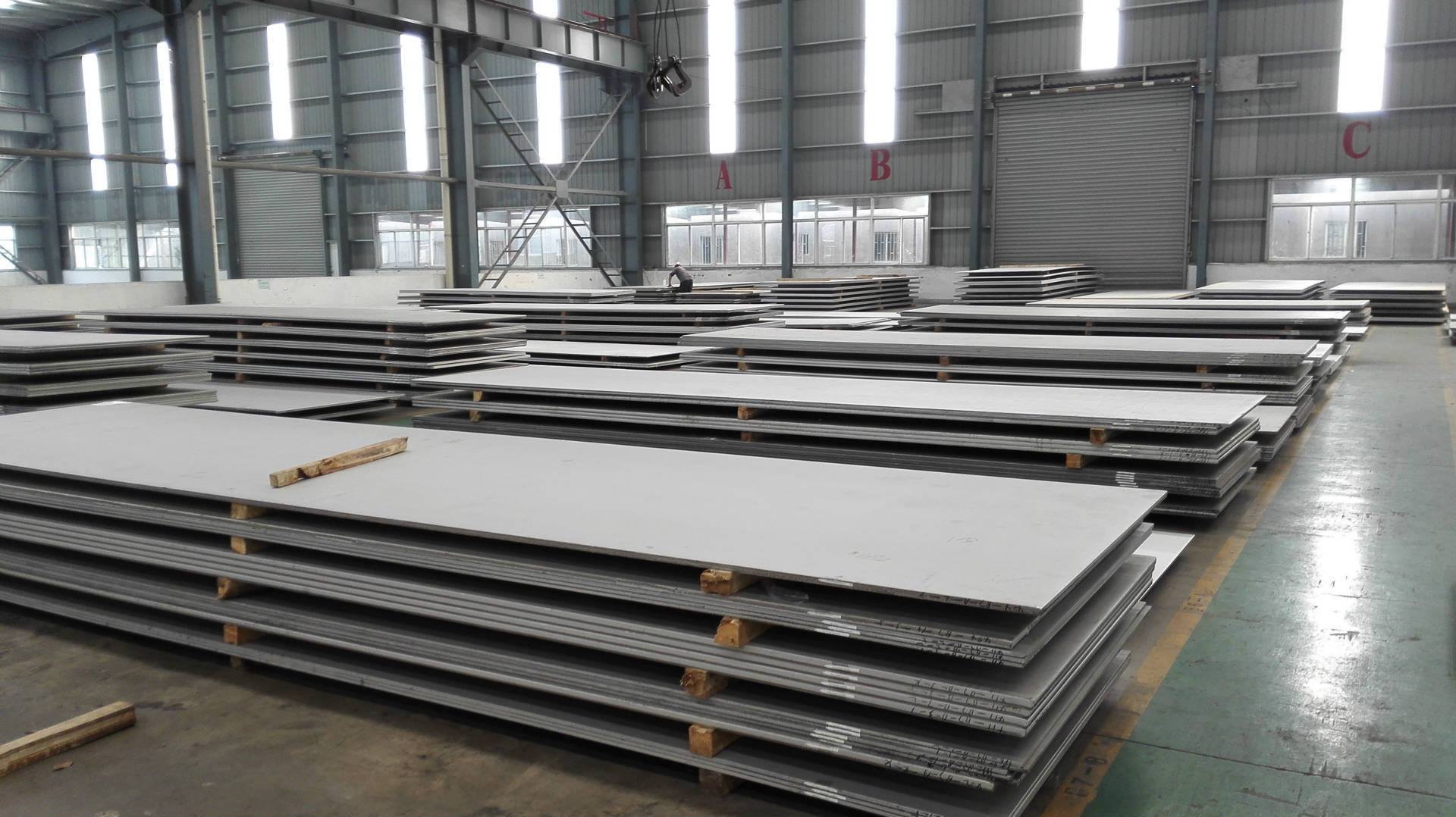

Stainless Steel Plate Standard Dimensions

1. Stainless steel plate and material: 304, 316L, 321, 201, (301 tape) Domestic stainless steel plate: 430, 409, 201.

2. Stainless steel plate 304 plate thickness 0.12mm-65mm stainless steel plate 316L# plate thickness 0.5mm-16mm.

3. Plate surface treatment: 8K mirror surface, 2B smooth surface, sanding (drawing, brushed sand), titanium gold, rice grain, oil surface drawing, BA board.

4. Plate width: 1000mm*2000mm, 1219mm*2438mm, 1219*30481219*3500, 1219*4000, 1500mm*3000mm, 1500mm*6000mmm.

What are the methods of cutting stainless steel plate

1. Flame cutting: The cost of this equipment is low. Although it is one of the few cost-effective methods for cutting thick metal plates, there are still defects in thin plate cutting. Compared with plasma, flame cutting has a larger heat-affected zone and greater thermal deformation.

2. Laser cutting: Laser cutting equipment can cut stainless steel plates less than 30mm, and after adding oxygen to the laser beam, it can cut 40mm thick carbon steel, but after oxygen cutting, a thin oxide film will be formed on the surface.

3. Wire cutting: Wire cutting processing is called wire cutting. Developed on the basis of EDM piercing and forming. It not only develops the application of EDM, but also replaces the perforation and molding of EDM in some aspects.

4. Edge trimming: edge trimming uses a movable upper blade and a fixed lower blade, and uses a suitable blade gap to apply shear force to metal plates of different thicknesses to cut and separate the plates according to the required size. The former is a forging machine whose main function is the metalworking industry.

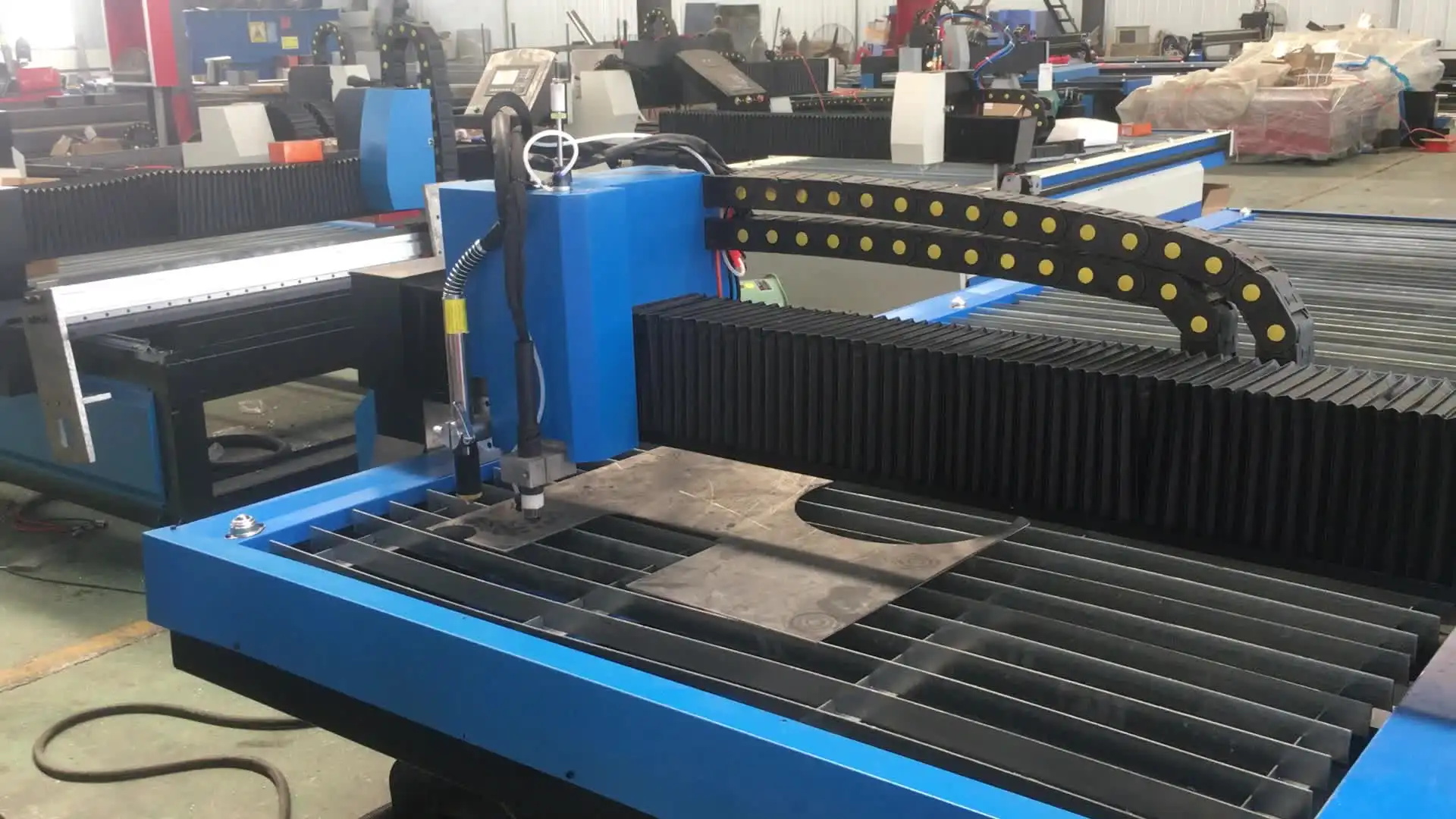

5. Plasma cutting machine: This cutting method is to melt the metal in the incision of the workpiece through high-temperature plasma heat, and remove the molten metal with the momentum of high-speed plasma to form the incision.

Everyone must choose the right steel plate. After all, the specifications of the steel plate are different for different purposes. It is not that the thicker the better, but it depends on your own needs and chooses the appropriate thickness according to your needs.

Post time: May-19-2023