Advantages:

1. The lower the thickness of the sheet the more beautiful and efficient

2. Embossing increase the strength of material

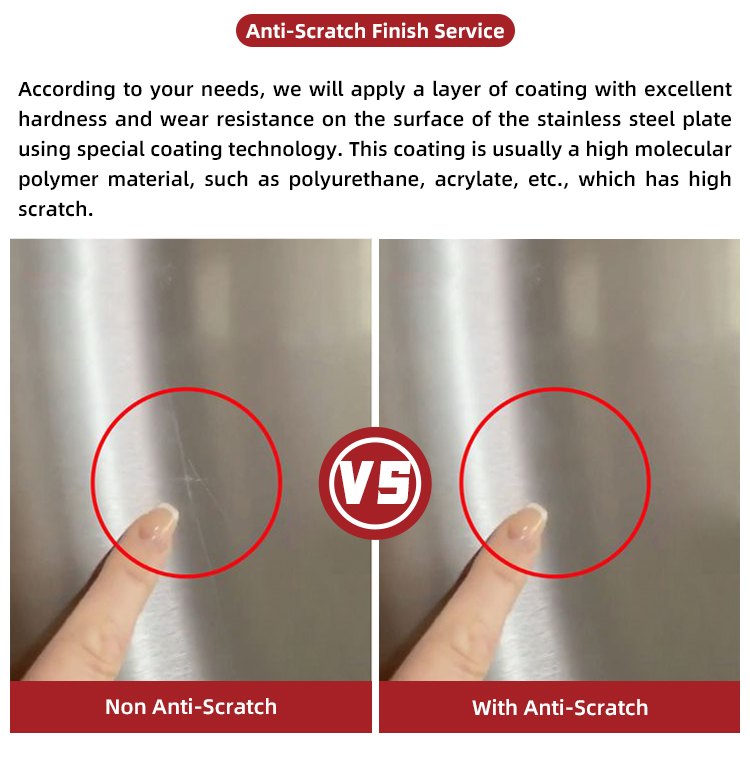

3. It makes the surface of the material scratch free

4. Some embossing gives a tactile finish appearance.

Grade and sizes:

The main materials are 201, 202, 304, 316 and other stainless steel plates, and the general specifications and sizes are: 1000*2000mm, 1219*2438mm, 1219*3048mm; it can be undetermined or embossed in a whole roll, with a thickness of 0.3mm~2.0mm.

How the embossing process typically works:

1. Stainless Steel Sheet Selection: The process begins with selecting the appropriate stainless steel sheet. Stainless steel is chosen for its durability, corrosion resistance, and overall aesthetic appearance.

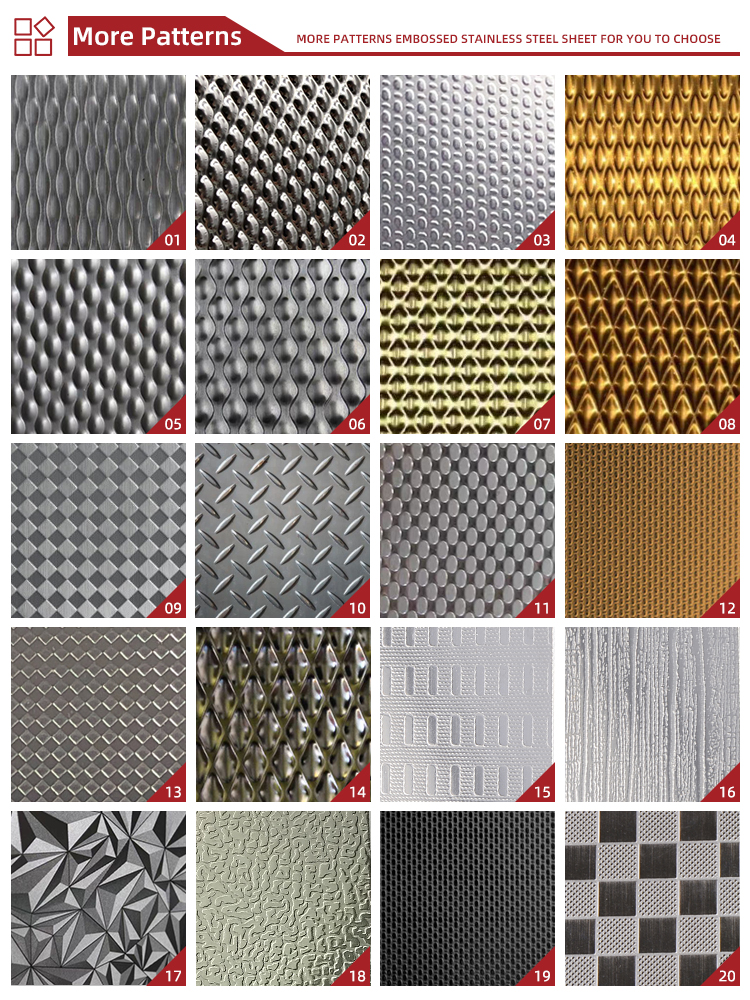

2. Design Selection: A design or pattern is chosen for the embossing process. There are various patterns available, ranging from simple geometric shapes to intricate textures.

3. Surface Preparation: The stainless steel sheet’s surface is thoroughly cleaned to remove any dirt, oils, or contaminants that could interfere with the embossing process.

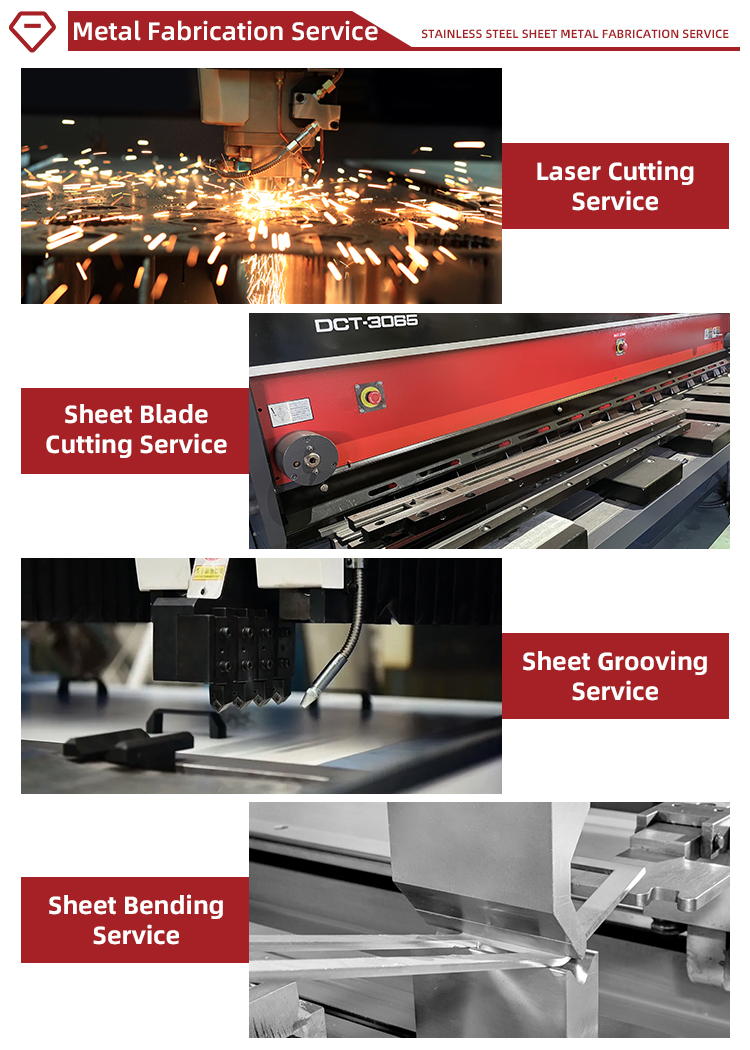

4. Embossing: The cleaned stainless steel sheet is then placed between embossing rollers, which apply pressure and create the desired pattern on the sheet’s surface. The embossing rollers have the pattern engraved on them, and they transfer the pattern to the metal as it passes through.

5. Heat Treatment (Optional): In some cases, after embossing, the stainless steel sheet may undergo a heat treatment process to stabilize the metal’s structure and relieve any stresses created during embossing.

Conclusion

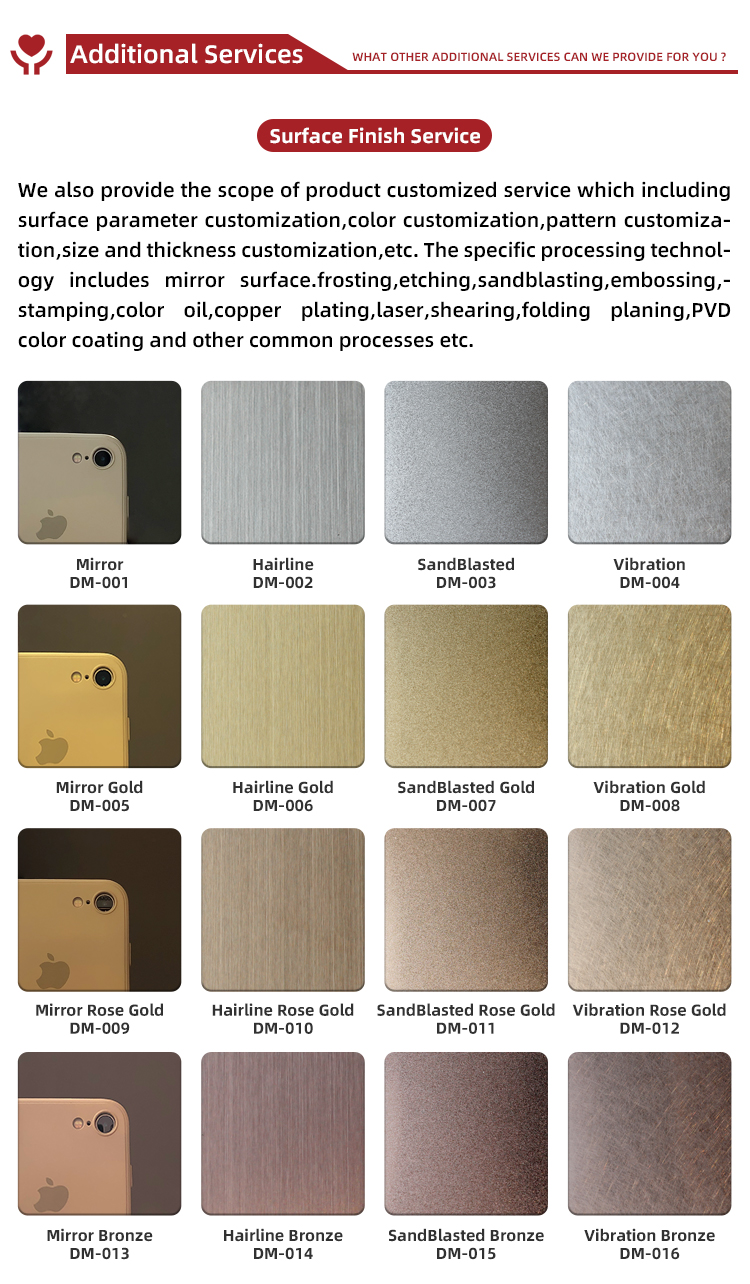

Stainless steel embossed sheet with so many potential applications. Contact Hermes Steel today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs. Please feel free to CONTACT US

Post time: Sep-15-2023