Thin stainless steel sheets can be cut using a variety of methods, depending on the precision, speed and complexity of cutting required. Here are some common techniques for cutting stainless steel sheet:

1,Shearing: Shearing is a simple and effective method for making straight cuts in stainless steel sheets. It involves using a shear tool or guillotine tool to apply downward force and cut the material in a straight line. Cut is suitable for straight cuts without complex shapes or curves.

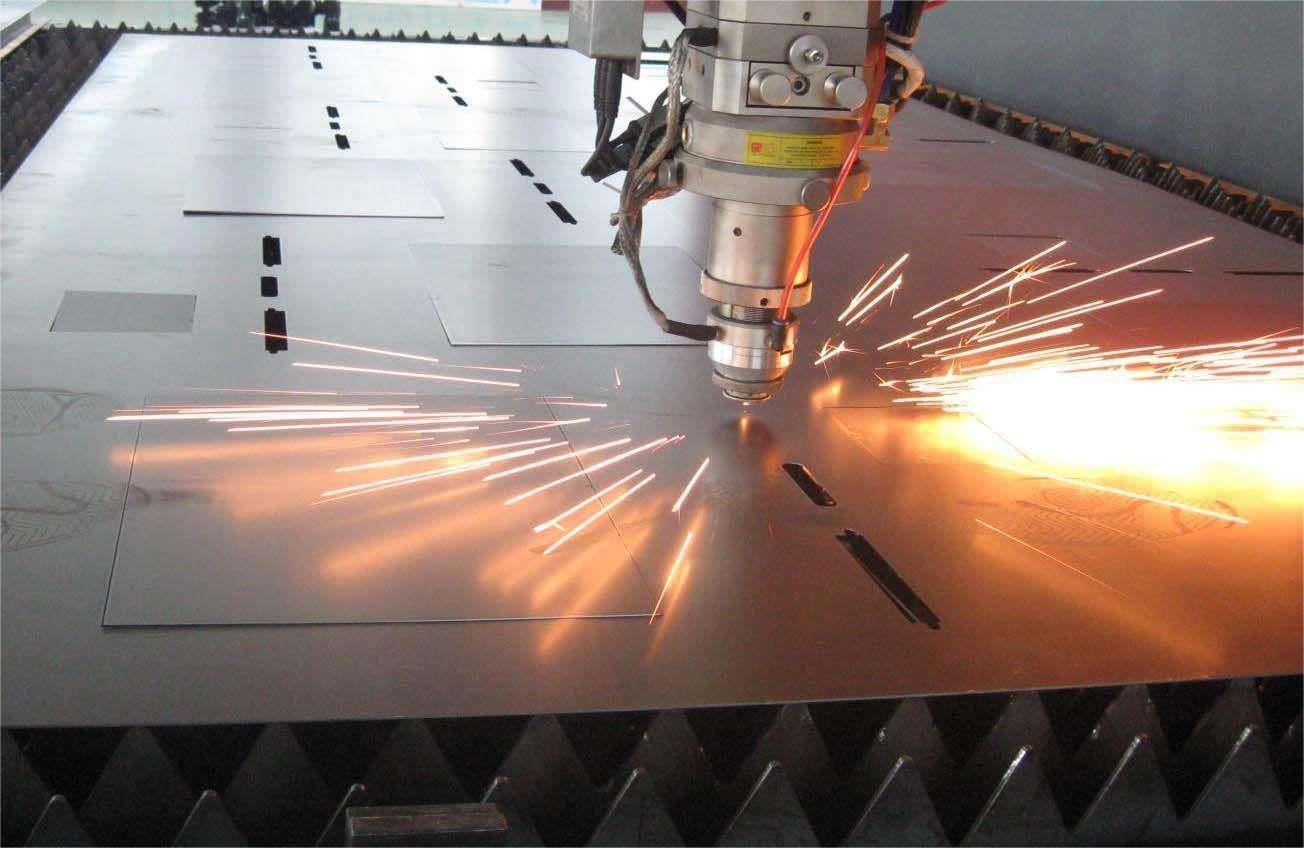

2,Laser Cutting: Laser cutting uses a high-powered laser beam to melt, burn, or vaporize stainless steel along a programmed cutting path. Laser cutting offers high precision and versatility, allowing complex shapes to be cut precisely. This is the preferred method for thin stainless steel sheets that require precise cuts or complex designs.

3,Waterjet Cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive particles to cut stainless steel sheets. Waterjet cutting enables precise cutting of a variety of shapes and thicknesses, including thin sheets. This is a cold cutting process that generates no heat, minimizing the risk of thermal deformation.

4,Plasma cutting: Plasma cutting uses a high-temperature plasma arc to melt and cut stainless steel plates. It works on both thin and thick plates, allowing for fast, precise cutting. Plasma cutting is commonly used in industrial applications and can process stainless steel plates of various thicknesses.

5,Electrical Discharge Machining (EDM): EDM is a precision machining method that uses electric sparks to etch and cut stainless steel plates. It is ideal for complex and precise cuts, including internal cuts and complex shapes. Compared to other methods, the EDM process is slow but highly accurate and can effectively process thin stainless steel sheets.

When using any of these cutting methods, it is important to wear appropriate personal protective equipment (PPE), follow safety guidelines, and ensure the work area is well ventilated. Additionally, selecting the most appropriate cutting method will depend on factors such as the quality of the cut required, complexity of the design, available equipment, and budget considerations.

Post time: Nov-09-2023