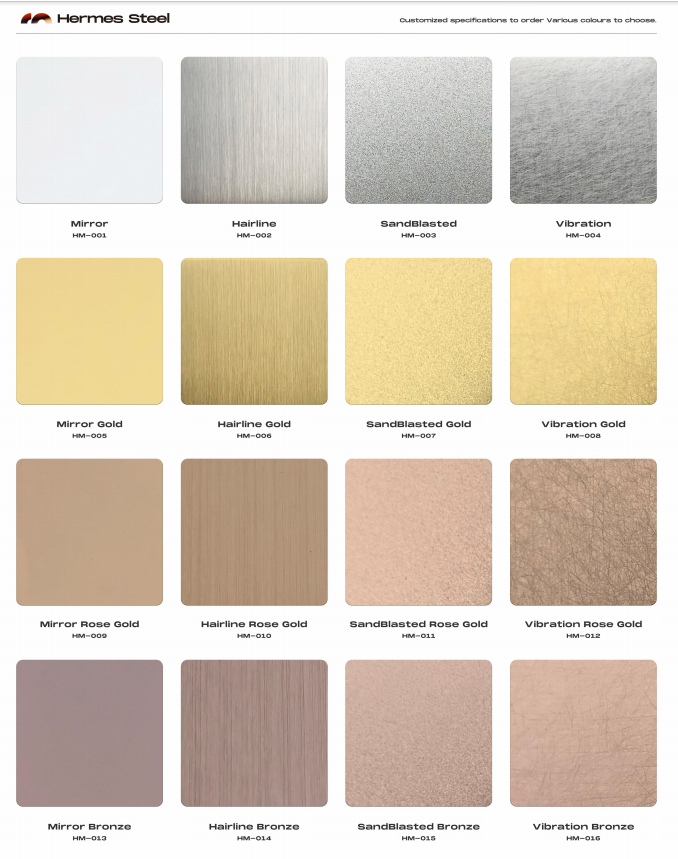

Although mirror stainless steel is called mirror surface, it also has grade distinctions. This grade refers to the roughness of the stainless steel surface. Different grades represent different surfaces. For example, 8k and 12k mirror stainless steel represent different surface effects, but this distinction is obvious. Not refined enough! Because the surface effect of the stainless steel surface is distinguished by k number. It is only a rough concept. Without comparison, it is difficult to distinguish!

We’ve put together a list to make the distinction between stainless steel grades easy to find!

Surface grade |Surface roughness |Surface effect

Stainless steel surface finish level 14 Ra 0.012~0.03μm 14k mirror stainless steel, excellent surface effect (ultra-fine polished stainless steel)

Stainless steel surface finish level 13 Ra 0.015~0.02μm 12k mirror stainless steel, excellent surface effect (super fine polished stainless steel)

Stainless steel surface finish level 12 Ra 0.02~0.16μm 10k mirror stainless steel, excellent surface effect (fine polished stainless steel)

Stainless steel surface finish level 11 Ra 0.1 ~0.2μm 8k mirror stainless steel, good surface effect (fine polished stainless steel)

Stainless steel surface finish level 10 Ra 0.2 ~0.3μm 6k mirror stainless steel, BA stainless steel, original condition shipped from the steel factory

Stainless steel surface finish level 9 Ra 0.4 μm 4k has almost no brightness, also called 2B surface (matte surface) no brightness

Stainless steel surface finish level 8 Ra 0.8 μm No mirror effect, processing traces can be micro-recognized, unpolished surface

Stainless steel surface finish level 7 Ra 1.6 μm No mirror effect, the direction of processing marks can be identified, unpolished surface

Stainless steel surface finish level 6 Ra 3.2 μm No mirror effect, no processing marks visible, unpolished surface

Stainless steel surface finish level 5 Ra 6.3 μm No mirror effect, slight processing traces visible, unpolished surface

Stainless steel surface finish level 4 Ra 12.5 μm No mirror effect, visible processing marks, unpolished surface

Stainless steel surface finish level 3 Ra 25 μm, no mirror effect, very rough surface, very obvious processing traces, unpolished surface

Stainless steel surface finish level 2 Ra 50 μm, no mirror effect, very rough surface, very obvious processing marks, unpolished surface

Stainless steel surface finish level 1 Ra 100 μm, no mirror effect, very rough surface, very obvious processing marks, unpolished surface

The higher the grade of stainless steel, the better the surface effect of stainless steel! The higher the grade, the brighter, smoother, and smoother the surface! The grade of stainless steel is distinguished, which facilitates our comparison and detection of stainless steel surface effects. Different effects correspond to different uses. That’s simple and clear!

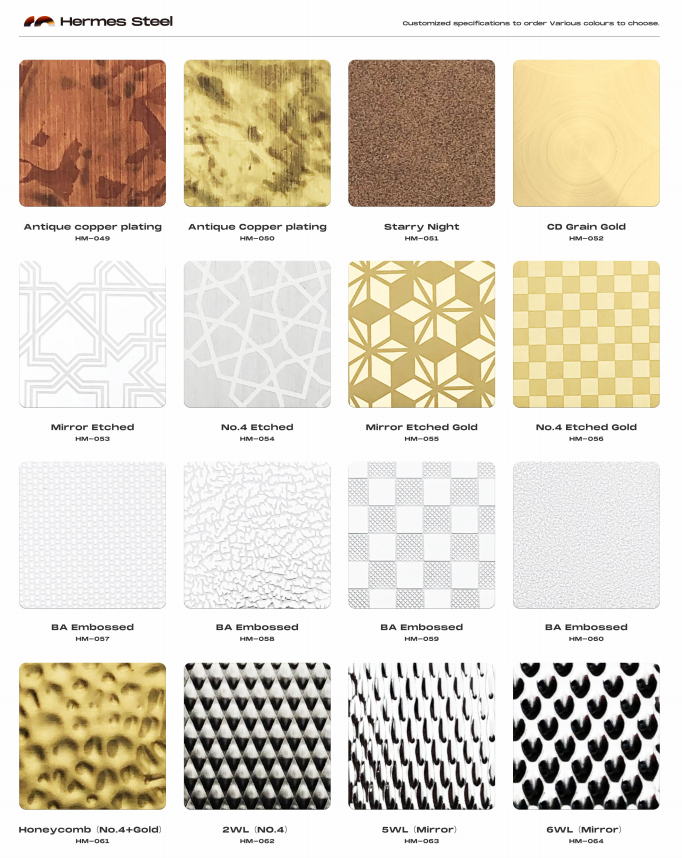

The raw materials shipped from large stainless steel mills are all stainless steel in its original state, basically without any processing. The surface effect is also post-processed, and the roughness also varies according to different manufacturers! The polishing effect is achieved after polishing in the processing plant. It can be tape polishing, plate polishing, or finished product polishing of small workpieces! Of course, the surface effect is not only polishing, but also many surface processing that do not require high surface roughness, such as embossing, brushing, frosting, etc. !

Conclusion

The application of mirror stainless steel sheets is limited only by imagination and creativity. Their ability to combine functionality with distinctive aesthetics makes them a versatile choice for a wide range of design and architectural projects.With so many potential applications, these sheets are sure to add a touch of elegance to any space. Contact Hermes Steel today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs. Please feel free to CONTACT US!

Post time: Sep-14-2023