Introduction:

Stainless steel embossed plates have emerged as a popular choice for both residential and commercial spaces due to their stylish appearance, durability, and versatility. This article will delve into the various aspects of stainless steel embossed plates, including their definition, dimensions, prominent features, selling points, and the production process.

1. Definition and Composition:

Stainless steel embossed plates are specialized plates created from high-quality stainless steel material. These plates exhibit a distinct pattern or design, enhancing their aesthetics and making them visually appealing. They are commonly used in architectural, interior design, and decorative applications.

2. Size and Thickness:

Stainless steel embossed plates come in various dimensions to suit different project requirements. Typical sizes range from small decorative panels (12 x 12 inches) to large wall-covering plates (48 x 96 inches). Thicknesses may vary from 0.03 inches to 0.125 inches. The availability of different sizes ensures that these plates can be used in diverse settings, offering flexibility in design.

3. Features and Selling Points:

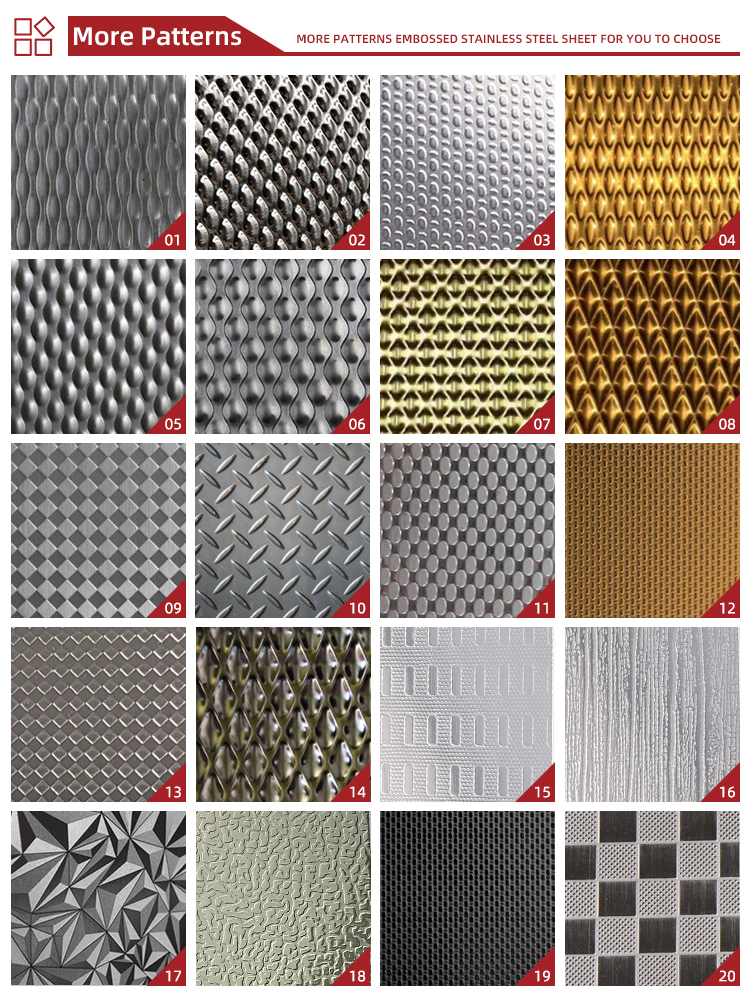

3.1 Enhanced Aesthetics: The embossed patterns on stainless steel plates introduce texture and depth, adding an appealing visual element to any space. These plates can seamlessly blend with modern or traditional interiors, acting as functional art pieces.

3.2 Durability and Corrosion Resistance: Constructed from corrosion-resistant stainless steel, embossed plates demonstrate exceptional durability. They exhibit resistance to rust, tarnish, and weathering, ensuring long-lasting performance, even in harsh environments or high-traffic areas.

3.3 Easy Maintenance: Stainless steel embossed plates are effortless to clean and maintain. Regular wiping with a mild detergent or stainless steel cleaner keeps them looking pristine. The smooth surface resists staining, smudging, and fingerprints, making them ideal for public spaces.

3.4 Versatility: These plates offer versatility in applications. They can be used as wall cladding, elevator panels, decorative screens, backsplashes, and more, providing endless design possibilities.

4. Production Process:

Stainless steel embossed plates are typically manufactured using a combination of traditional metalworking techniques and modern machinery.

4.1 Material Selection: High-quality stainless steel sheets are chosen based on their desired finish, thickness, and composition, ensuring optimal performance.

4.2 Embossing: The chosen stainless steel sheets are placed through specialized embossing machines that imprint the desired pattern or design onto the surface of the plate. This intricate and precise process ensures consistent embossing on each plate.

4.3 Cutting and Finishing: After embossing, the plates are cut to the desired sizes using industrial-grade cutting tools. Edges are smoothened, and surfaces are buffed to achieve a uniform finish.

4.4 Quality Control: The final product undergoes rigorous quality checks to ensure precision, durability, and adherence to industry standards before being prepared for market distribution.

Conclusion:

Stainless steel embossed plates offer an ideal blend of aesthetics and functionality, making them a sought-after choice in various architectural and design projects. Their durable construction, ease of maintenance, versatility, and intriguing embossed patterns make them a valuable asset for both interior and exterior applications. By understanding the dimensions, features, and production process behind stainless steel embossed plates, individuals can make informed decisions when incorporating these plates into their spaces.

Post time: Nov-14-2023