Stainless steel surface processing type

When stainless steel comes out of large steel mills, it comes in a full roll with a fog-like surface, commonly known as the 2B side. There is also a surface called the BA side. The brightness of this surface is generally called 6K. So the various colors, patterns, and The shaped stainless steel plates are all processed later. The width of steel coils in large steel mills is limited, one is 1219mm wide, one is 1000mm wide, and the other is 1500mm wide. Therefore, there are no decorative stainless steel plates with a width of 1800mm and a length of 1900mm on the market.

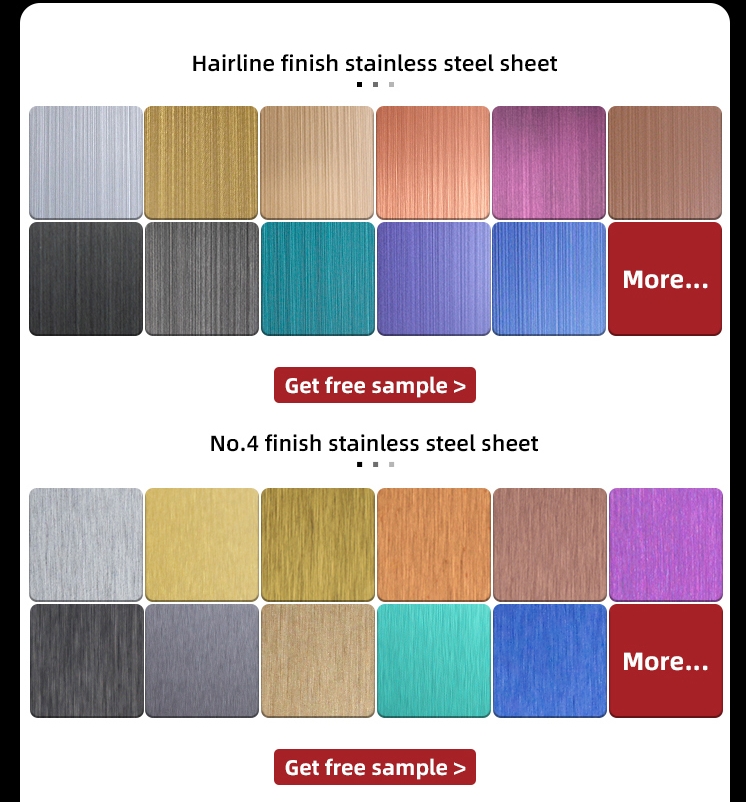

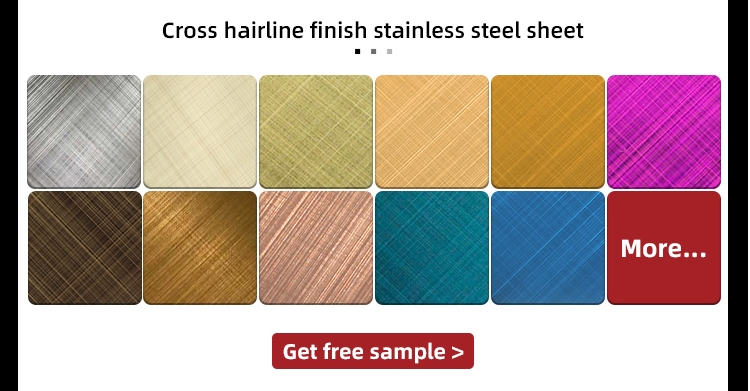

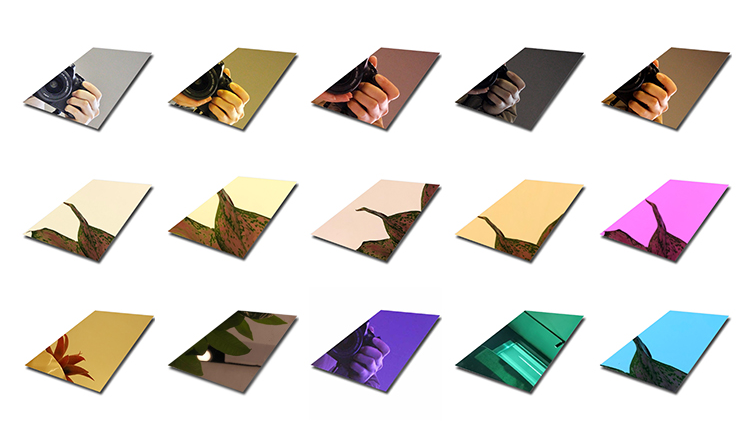

Surface processing:

1. Mirror surface (also called 8K): Mirror surface means that the stainless steel plate is polished by a machine to look like a mirror, which is bright and shining. Stainless steel coils can also be mirror-finished.

2. Brushed, NO.4, Ordinary Sand: Brushed, Snowflake Sand, and Ordinary Sand are also collectively referred to as frosted. These three kinds of surface stainless steel are mainly called the same because of the different sand patterns on the surface. The sand texture of brushed sand is the thickest and longest, followed by ordinary sand, and the sand texture of snowflake sand is the smallest and finest. Of course, their processing machine requirements are also different. The value is that there are currently manufacturers that require the surface to be made of mixed sand. For example, it is necessary to grind snowflake sand once and then do drawing. Stainless steel coils can also be processed in this way.

The above two are the most basic processing.

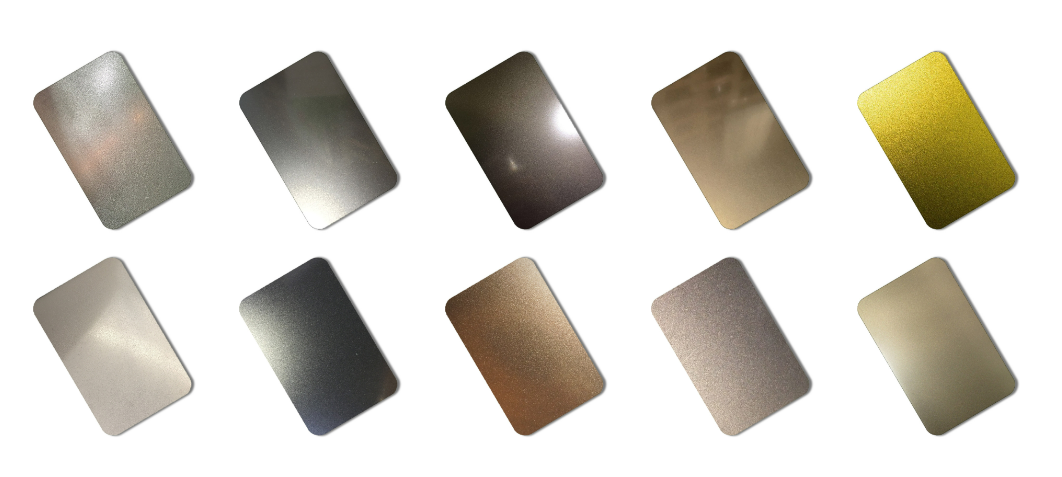

3. Sandblasting: This means that the surface of the stainless steel plate presents a fine bead-like sand surface. However, stainless steel sandblasting is divided into matte sandblasting and bright sandblasting. Matte means that the board is sandblasted when it is still on the 2B surface, and glossy means after polishing the mirror surface. In theory, stainless steel coils can be used for this kind of processing, but there is currently no such production machine.

4. Vibration: also known as harmonious pattern. The surface of this processed stainless steel plate will show a circle of sand patterns when viewed from a distance, while it will appear as irregular and chaotic patterns when viewed from a close distance.

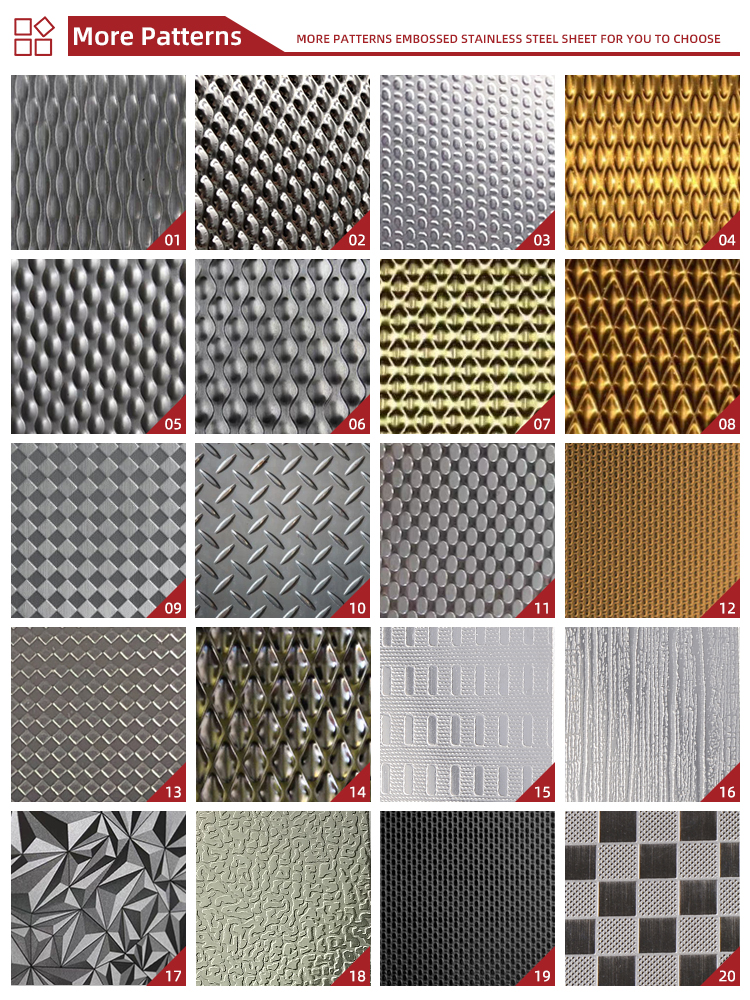

5. Embossing: Some people call it embossing, which is the stainless steel plate we see on the surface with small rhombuses, cubes, squares, and panda patterns. But when we do processing, it can only be done with rolled materials. This kind of processing cannot be done with a 4*8-foot plate. It needs to be embossed and then flattened to have the patterns we see. Stainless steel plate.

6. Titanium plating: What many people call colored stainless steel at present is actually a plate with a certain color on the surface after titanium plating, such as yellow titanium gold, rose gold, sapphire blue, etc. The machine required for titanium plating is called a titanium furnace. When doing coloring, the five pre-processed plates mentioned above can be colored, but after the embossed stainless steel pattern comes out, it needs to be polished to 6-8K with an 8K machine. Add color only for the best effect. There is another need in titanium plating. What is proposed is to make black titanium, which can be done with a titanium furnace. However, the most commonly used method at present is to plating black titanium with water. The potion is prepared according to a certain ratio, and then the plate is placed in the potion. In the pool, electrolysis makes the surface of stainless steel appear black. Generally speaking, the effect of water plating black titanium is better than that of vacuum plating. Therefore, many people refer to plates made of rose gold as rose gold stainless steel, or titanium plates.

7. Etching: It is to use chemical agents on the surface of stainless steel to make it appear uneven, or with some text or patterns. Generally, the plates used for etching have been pre-processed. They can be colored first and then etched, or they can be etched first and then colored. The etched pattern can be etched according to the pattern or text required by the customer, and there is no trace of the front pattern on the back of the etched plate.

8. Titanium removal: Some people call the plate after titanium removal called colored stainless steel. As the name suggests, titanium removal is first plating titanium on the plate, and then the color is removed at a designated location to achieve a specific pattern and shape.

9. Laser: This process is currently used in many aspects. However, the specific processing manufacturer is currently confidential.

10. Anti-fingerprints: A layer of oil is attached to the surface of the stainless steel plate and dried to achieve anti-fingerprint and anti-oxidation effects.

11. Colored stainless steel: Colored stainless steel in the stainless steel industry refers to: making patterns on the surface of stainless steel that has undergone basic treatment. Different from titanium, etching, and embossing. The pattern can be completely determined by the customer. For example, customers can choose to make “Along the River During the Qingming Festival” or a color that cannot be made with titanium. The surface of the board made with this process looks like plastic, and the color and pattern are durable.

12. Laminated Sheet: The printed film product is compounded to the surface of the stainless steel plate by pasting it, which can produce very exquisite patterns and patterns.

13. Copper plating: The surface of stainless steel is plated with copper. Some customers say that all they need is a copper color, so they choose titanium-plated bronze. There are also many customers who require the plates to be aged and antiqued, which requires water-plated bronze or water-plated red copper. When doing water copper plating, the surface does not need to be treated, because even if it is treated, it will be covered by the copper element. After copper plating, black silk is applied, and finally it is done without fingerprints. When you cut open the surface of this plate, what you see is not the true color of stainless steel, but the color of copper.

14. Composite color plate: It is compounded on the basis of these processes.

Post time: Dec-14-2023