MATERIAL GRADE

The basic material of Water Ripple™ is stainless steel. Hermes steel® provides two high-quality Grade 304 or 316L(Standard: ASTM)

Selections are defined by the application scenarios.

| Stainless steel Grade | Description | Application |

| 304 |

304 grade is the most common form of stainless steelused around the world.Due to it contains between 16to 24 percent chromium, 304 stainless steel has highresistance to rust.lt with stands corrosion from mostoxidizing acids. |

Most interior situation |

| 316L |

Different from 304,316Lincorporates about 2 to 3percent molybdenum, which increases corrosionresistance-particularly against chlorides and otherindustrial solvents |

Coastal regions; |

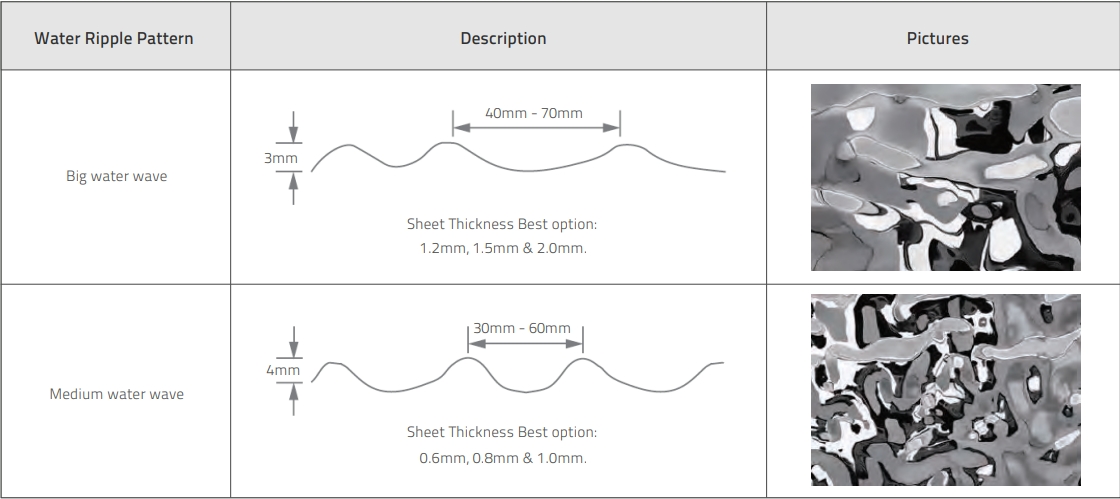

PATTERN

Water Ripple™ pattern is multiplied by the wave distance and height.

Note: Due to the production process, no two sheets are exactly alke. Some finish irregularities as wellas color and ripple variations wil appear. Wecheck the color difference and integrity of the material before cutting or instalation to ensure that the material does not affect the overallinstalation and splicing work.

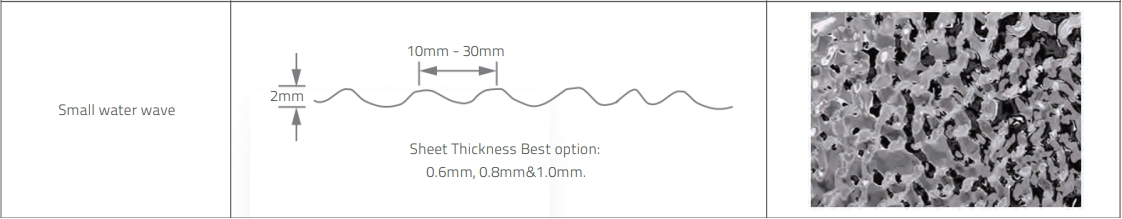

COLOR & ANTI-FINGERPRINT

Different colors can present differnt styles and effects to match different needs and requirements.

Unmatched wide various color can be choosed in Hermes steel®.

Anti-fingerprint is an invisible, extremely thin and protective treatment that significantly improvethe resistance to corrosion and fingerprint and maintenance ease of Water Ripple™ .

Note: For more color selections, please contact us.

Please feel free to contact us for color sample, because different computers will render colors.

DIMENSIONS

Our recommends the standard Water Ripple™ sheet size

| Thickness | Regular Size | Tolerance | Edge | Weight |

| 0.3mm-3mm |

1000mmx2000mm;1219mmx2438mm 1219mmx3048mm;1500mmx3000mm Customed:Width<=2000mm,Length<=6000mm |

±0.3% | Mill, Slit |

Grade-304:79.3 x10Λ4kg/m³ |

PROTECTIVE FILM

| Functions | PE film certificated by ROHS in EU prevents the surface from dirt or water-logging while transportation, machining and installation. |

| How to remove? | Take one coner with the angle less than 90° slowly and regularly to remove. |

PROPERTIES RELATED TO WATER RIPPLE™ STAINLESS STEEL SHEETS

Density: The density of stainless steel water ripple sheets depends on the grade of stainless steel used. Generally, stainless steel has a density ranging from 7.75 to 8.05 g/cm³.

Thermal Conductivity: Stainless steel has a relatively low thermal conductivity compared to other metals like aluminum or copper. This property can be advantageous in certain applications where thermal insulation is required.

Magnetic Properties: Austenitic stainless steels, such as grades 304 and 316, are non-magnetic in their annealed condition. However, they can become slightly magnetic after cold working or during fabrication processes.

Tensile Strength: Tensile strength is the ability of a material to resist tensile force. Different grades of stainless steel have different tensile strengths, usually between 500 MPa and 1000 MPa.

Yield Strength: Yield strength is the stress level at which a material begins to plastically deform. Different grades of stainless steel have different yield strengths, usually between 200 MPa and 800 MPa.

Elongation: Elongation is the extent to which a material can plastically deform before it breaks. Stainless steel water corrugated sheets usually have a high elongation, usually between 30% and 50%.

Hardness: Hardness is the ability of a material to resist scratches and deformation. Stainless steel generally has a higher hardness, depending on its composition and how it is treated.

Flexural Strength: Flexural strength is the resistance of a material under bending loading. Stainless steel water corrugated sheets generally have good bending strength and are suitable for applications requiring curved shapes or curved members.

Corrosion Resistance: One of the primary advantages of stainless steel is its corrosion resistance. This property makes stainless steel water ripple sheets suitable for use in both indoor and outdoor environments, including areas with high humidity or exposure to moisture.

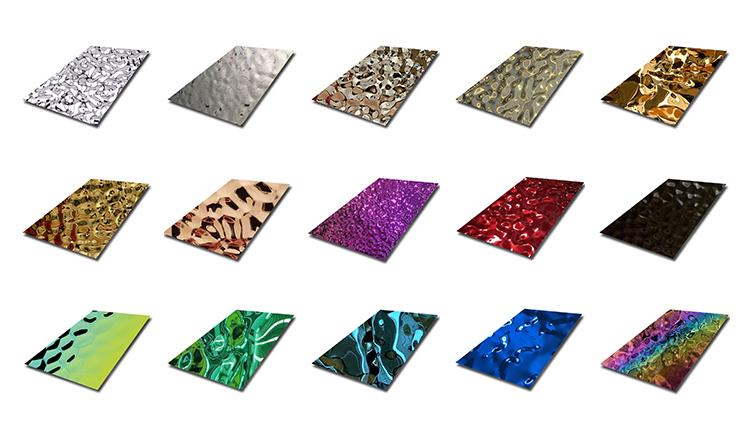

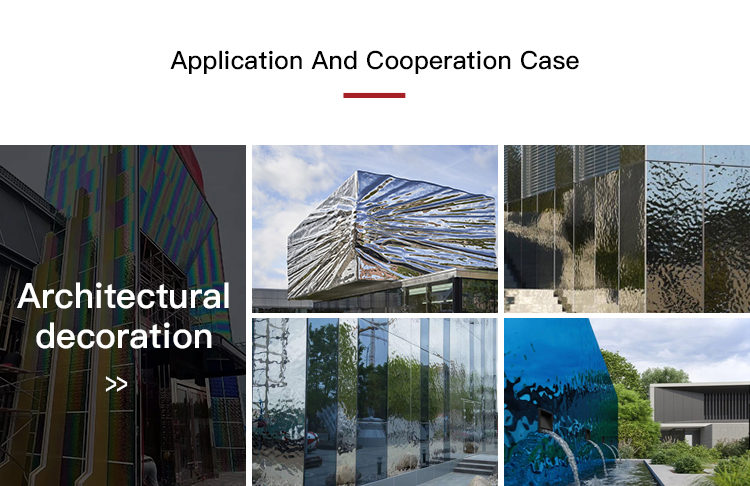

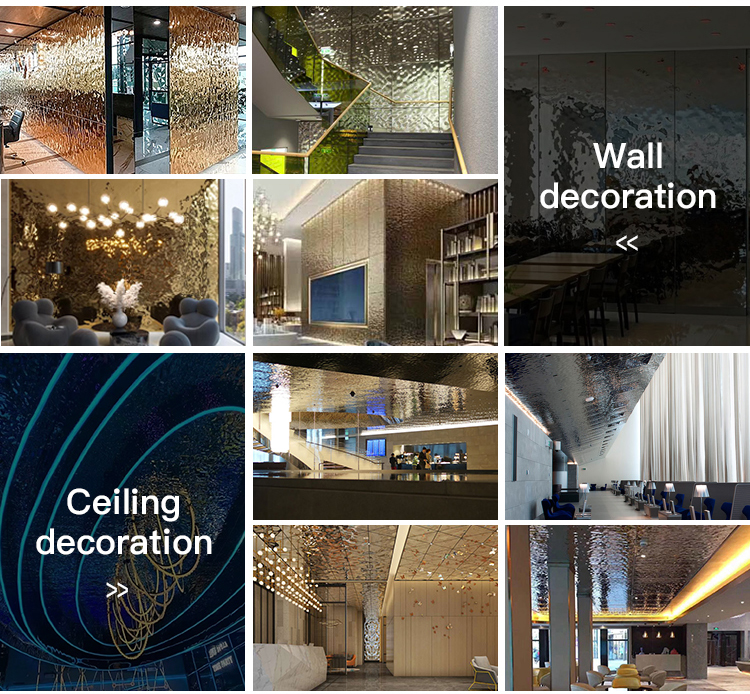

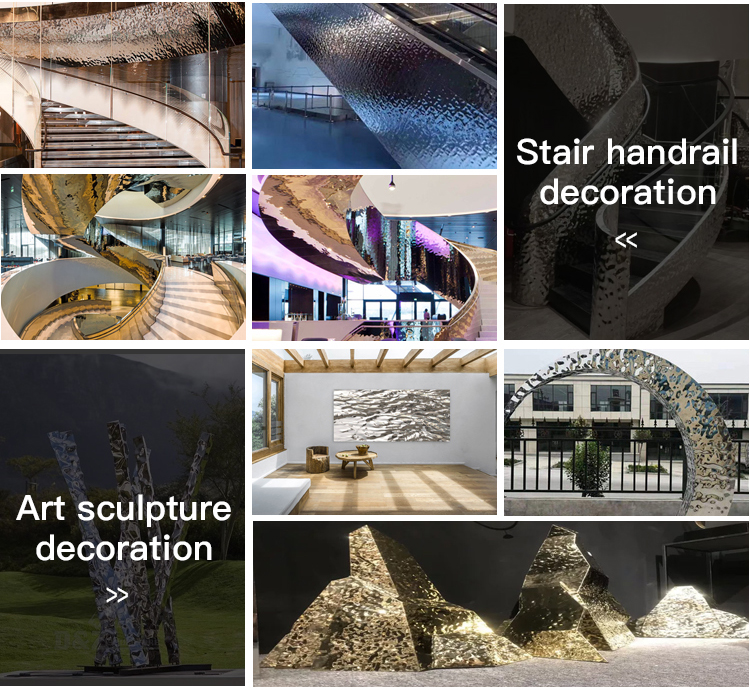

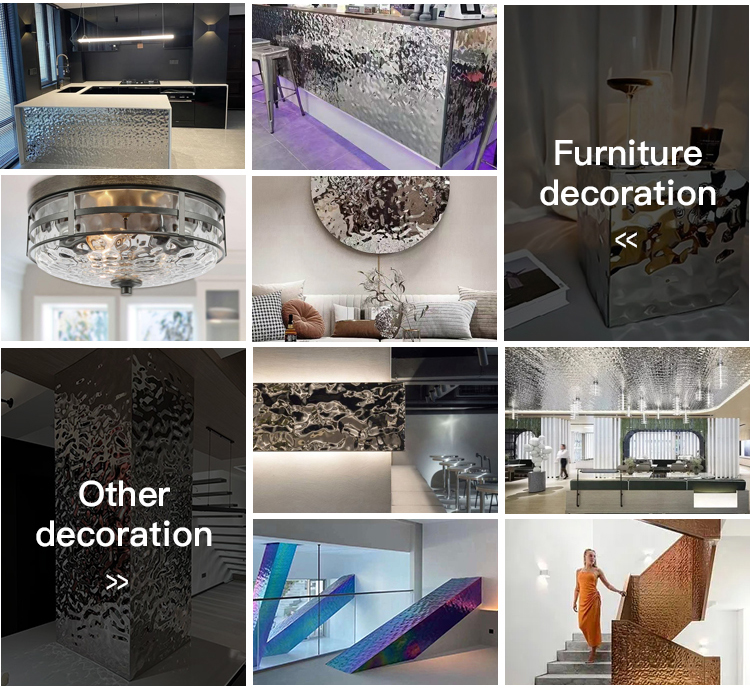

APPLICATIONS & MAINTENANCE

WATER RIPPLE™ itself is a decorative sheet with wide application in-built engineering and furnitureIt is easy to clean, especially with the anti-fingerprint. Usually a clean towel or microfiber with cleanwater can remove smudges.

| Applications |

In-built: Wall Cladding, Column Cladding, Elevator Cladding, CeilingFuniture: Display Case, Table top, Counter |

| Maintenance | Stainless steel is easy to clean. Washing with soap or a mild detergent and water, followed by a clear water rinse,is usually quite adequate for domestic and architectural product. An enhanced aesthetic appearance will be achievedif the cleaned surface is wiped dry. |

CONCLUSION

Water ripple stainless steel sheet is a plate made of stainless steel with a corrugated surface. This material is typically highly corrosion-resistant and mechanically strong, making it suitable for a variety of environments and uses. Commonly used in construction, decoration, household products, kitchen equipment, chemical equipment and other fields. Its corrugated surface adds rigidity and strength to the material while also giving the product a unique appearance.

Water corrugated stainless steel plate is a good decorative material. With so many potential applications, these boards are sure to add a touch of elegance to any space. Contact HERMES STEEL today to learn more about our products and services or to get a free sample. We’d be happy to help you find the perfect solution for your needs. Feel free to contact us any time!

Post time: Apr-13-2024