What is a Brushed stainless steel sheet?

A brushed stainless steel sheet, or stainless steel wire drawing plate, is a stainless steel plate after a surface treatment process. This treatment process is used to change the appearance and texture of the surface of the stainless steel plate to produce a specific visual effect and texture. During the brushing process, the surface of the stainless steel sheet is mechanically or chemically treated to create a specific texture, line, or gloss effect. This is sometimes called brushing, brushing, or polishing. Brushed treatment can produce different surface textures, such as mirror, matte, vertical grain, horizontal grain, etc., to meet additional decoration and design needs.

Brushed Stainless Steel Sheet Regular Size and Thickness

Conventional size:

Length: Usually between 1000 mm and 6000 mm, longer sizes can also be customized.

Width: Usually between 1000 mm and 1500 mm, wider sizes can also be customized.

Normal thickness:

Thickness: Usually between 0.3 mm and 3.0 mm, with different thicknesses required for different applications. In some special cases, thicker brushed stainless steel plates can also be found.

It is important to note that the specifications and sizes of brushed stainless steel plates can be customized according to different project needs, so it is best to communicate in detail with the supplier or manufacturer at the time of purchase to ensure that you have the right size and thickness for your project.

Advantages of brushed stainless steel sheets

Brushed stainless steel sheets offer several advantages that make them a popular choice in various industries and applications. Here are some of the key advantages of using brushed stainless steel sheets:

1. Aesthetic Appeal

2. Reduced Reflectivity

3. Tactile Sensation

4. Durability and Corrosion Resistance

5. Low Maintenance

6. Versatility

8. Environmental Benefits

9. Light Interaction

10. Premium Look

What process can brushed stainless steel sheet do?

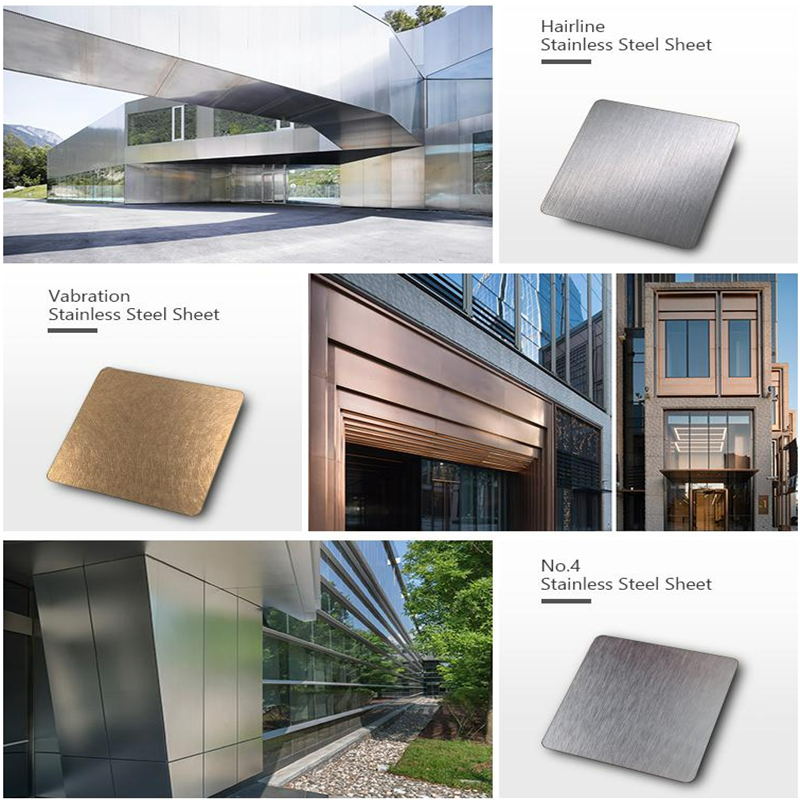

• hairline stainless steel sheet: A hairline stainless steel sheet refers to a type of stainless steel sheet that has undergone a surface treatment process called “hairline finishing” or “hairline brushing.” This finishing process creates a subtle, fine-line texture on the surface of the stainless steel sheet, giving it a brushed appearance with a soft and smooth texture. The lines created by the hairline finish are typically uniform and run in one direction, adding a touch of elegance and sophistication to the material.

• No.4 stainless steel sheet: A No. 4 stainless steel sheet, also known as a brushed or satin stainless steel sheet, is another type of surface finish applied to stainless steel sheets. The No. 4 finish is achieved through a mechanical polishing process that creates a uniform, non-reflective, and textured surface. This finish is characterized by its fine lines or brush strokes that run in a consistent direction.

• Vibration stainless steel sheet: A vibration stainless steel sheet, also known as a vibration finish or textured stainless steel sheet, is a type of surface finish applied to stainless steel sheets to create a distinctive and textured appearance. This finish is achieved through a mechanical process that produces a pattern of parallel lines or waves on the surface of the stainless steel.

• Cross Hairline stainless steel sheet: A cross hairline stainless steel sheet is a type of surface finish applied to stainless steel sheets that features a unique and intricate pattern resembling intersecting lines. This finish is often used for decorative and architectural purposes to create visually appealing designs and textures on stainless steel surfaces.

How to polish the brushed effect from stainless steel?

Polishing the drawing effect from stainless steel usually requires the following steps:

Preparation: Prepare the required materials and tools, including stainless steel surface treatment agent, sandpaper, polishing machine, stainless steel brush, polishing wheel, polishing paste, etc.

Surface cleaning: First, ensure that the stainless steel surface is clean and dust-free. The surface can be cleaned with a cleaner or detergent, then rinsed with water and dried.

Sanding: Initial sanding with an appropriate thickness of sandpaper to remove rough parts and oxides from the stainless steel surface. Usually, start with a coarser sandpaper and gradually transition to a finer sandpaper until the desired smoothness is achieved.

Drawing treatment: Use a tool such as a stainless steel brush or polishing wheel to draw the wire in the desired direction. This can create different textures and line effects. When drawing, a certain uniform pressure should be maintained to obtain a consistent effect. You can choose different types of stainless steel brush or polishing wheel according to your needs to obtain different drawing effects.

Polishing: Use a polishing machine and an appropriate polishing paste to polish the stainless steel surface. During the polishing process, attention should be paid to maintaining a uniform speed and pressure to ensure that the surface is smooth and bright. The polishing can be done several times, gradually transitioning to a finer polishing paste until the desired drawing effect and gloss are obtained.

Cleaning and protection: After finishing polishing, clean the stainless steel surface with a cleaner to remove residues and stains from the polishing process. It can then be protected with an appropriate stainless steel protectant or wax to extend the durability of the drawing effect and protect the stainless steel surface from oxidation and corrosion.

Application areas

Brushed stainless steel plates are widely used in many different fields because of their unique appearance and texture. Here are some common application areas:

Interior decoration: brushed stainless steel plate is often used in indoor walls, ceilings, floors, stair handrails, railings, decorative panels, and other decorative materials, giving the interior space a luxurious and modern appearance.

Home furniture: In furniture manufacturing, brushed stainless steel plate can be used to make tables, chairs, bed frames, cabinets, and other home furniture, to bring a modern sense and elegant texture to the home.

Commercial space: hotels, shopping malls, restaurants, cafes, and other commercial spaces often use brushed stainless steel plates to decorate the internal space, creating a high-end, fashionable atmosphere.

Kitchen appliances: Brushed stainless steel plate is used in the appearance design of kitchen appliances such as refrigerators, microwave ovens, ovens, range hoods, etc., which increases the beauty of the product.

Elevator interior: The walls, floors, handrails, and other parts of the elevator interior can be decorated with brushed stainless steel plates to enhance the comfort and modernity of the elevator interior.

Building facade: In some modern buildings, brushed stainless steel plates can be used to decorate the building facade, creating a unique visual effect.

Art sculpture: Artists can use brushed stainless steel plates to create sculptures, giving the work a unique texture and shine.

Decorative supplies: For example, various decorative frames, picture frames, tableware, flower POTS, etc., can be made using brushed stainless steel plates to add beauty to the details of life.

Display counter: The display counter in stores, exhibitions, and other places often uses brushed stainless steel plates to highlight the high quality and fashion sense of the products.

Transportation interior: Some high-end transportation vehicles such as trains, planes, and cruise ships can also see the application of brushed stainless steel plates, enhancing the comfort of passengers.

These are just a few examples of brushed stainless steel applications, in fact, it can be used for more different occasions, depending on the creativity and needs of designers and decorators.

Hermes Stainless Steel

As a premier stainless steel surface designer in China, Foshan Hermes Steel Co., Ltd established in 2006, which strives for stainless steel innovation and quality for more than 10 years. So far, we have developed into a large integrated enterprise of stainless steel material design, and processing.With twelve production equipment production lines, it can meet your various surface design needs

Conclusion

There are many reasons to choose brushed stainless steel sheets for your next project. These metals are durable, beautiful, and versatile. With so many potential applications, these sheets are sure to add a touch of elegance to any space. Contact HERMES STEEL today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs. Please feel free to CONTACT US!

Post time: Aug-11-2023