What is antique stainless steel sheet?

Antique stainless steel sheets go through a series of surface treatments to give them a weathered or aged appearance. Unlike regular stainless steel, which often has a shiny, brushed or matte finish, antique sheets have a unique and old-fashioned look that makes them stand out.

Stainless steel antique sheet features:

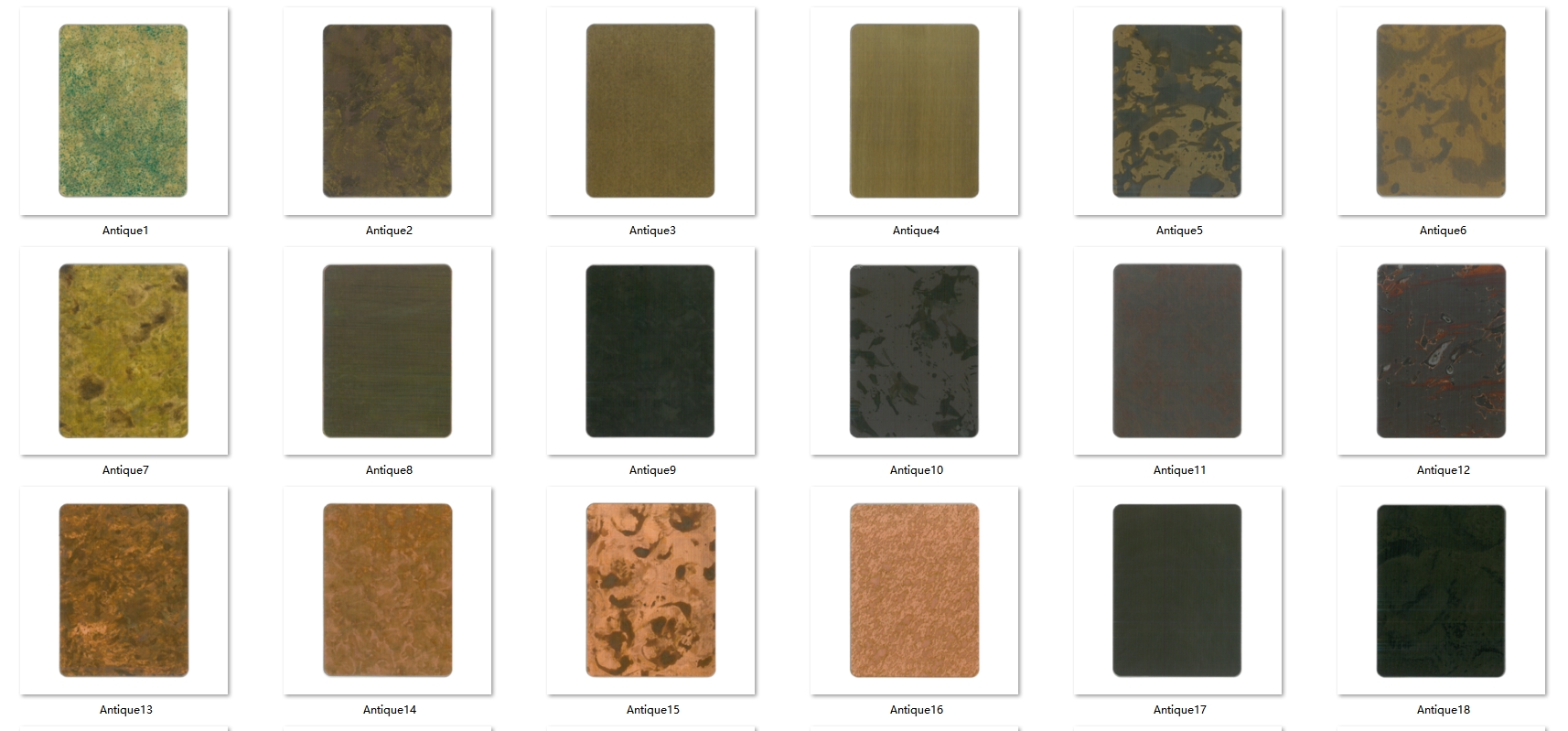

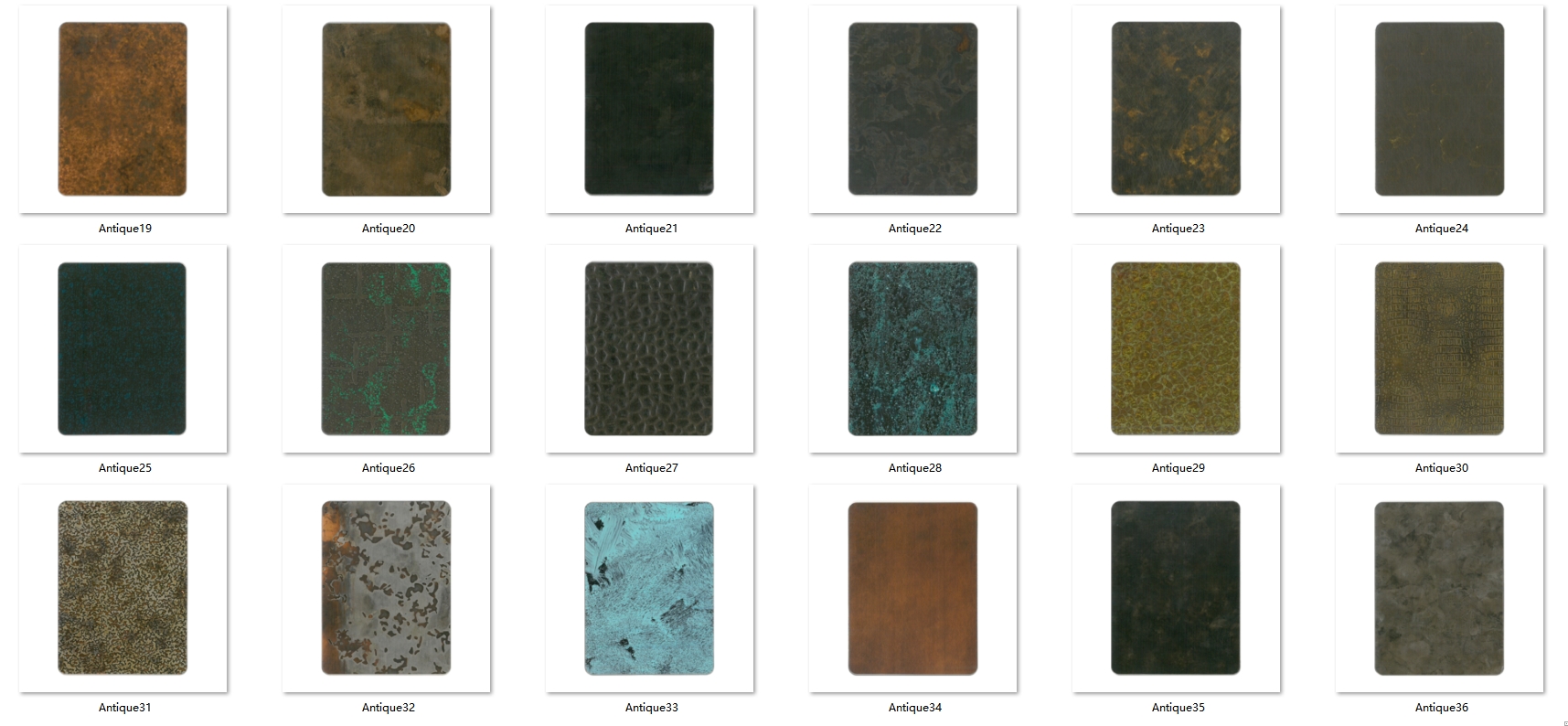

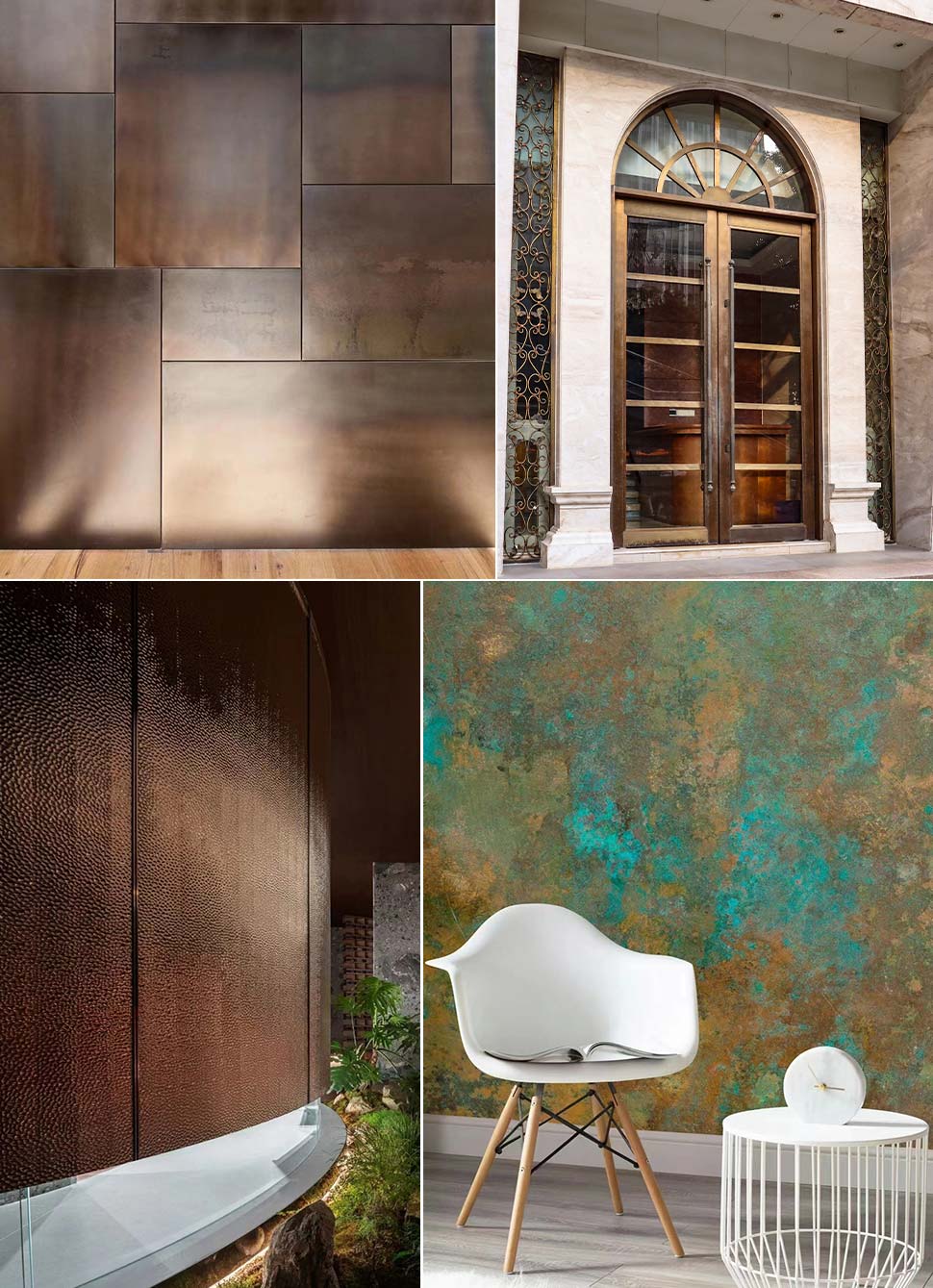

1、Variety of Finishes: These sheets come in a variety of finishes, including brushed, hammered, distressed, or patinated, to mimic the appearance of aged metal surfaces.

2、Durability: antique stainless steel sheets are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor applications.

3、Customization Options: Manufacturers often offer customization options such as different thicknesses, sizes, and finishes to suit specific design requirements.

4、Heat Resistance: They have excellent heat resistance properties, making them suitable for applications in kitchens, fireplaces, and other environments with high temperatures.

5、Unique Aesthetic: The aged appearance of antique stainless steel sheets adds a touch of uniqueness and character to any space, creating a visually striking focal point.

Distinctive Advantages of OurStainless Steel Antique Sheets:

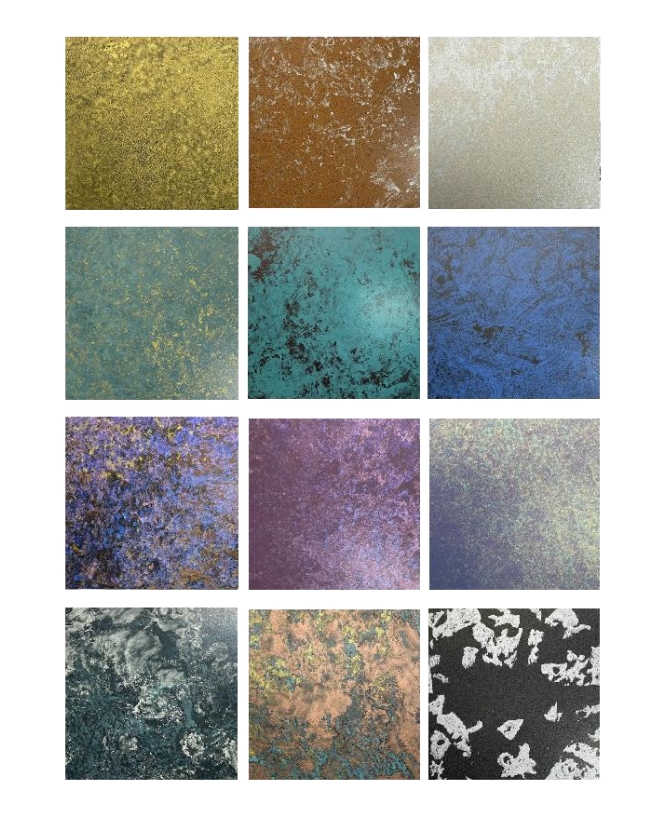

More patterns for choice:

Get Free Sample And Product Catalog,Pelase click contact us~

How is Antique stainless steel sheet Made?

Antique stainless steel sheets are typically made through a process called antiquing or distressing, which involves altering the surface of the stainless steel to achieve an aged or antique appearance. Here’s a general overview of how antique stainless steel sheets are made:

1.Preparation of Stainless Steel Sheets: The process starts with high-quality stainless steel sheets. These sheets are usually in standard sizes and thicknesses.

2.Surface Treatment: Various techniques can be used to create an antique effect on the surface of the stainless steel. Common methods include:

-

Chemical Treatments: Chemicals are applied to the surface of the stainless steel to induce oxidation or other reactions that alter the color and texture. These chemicals may include acids, bases, or other compounds that interact with the stainless steel to produce the desired effect.

-

Mechanical Distressing: Physical techniques such as sandblasting, wire brushing, or grinding can be used to create texture and patterns on the surface of the stainless steel. This process can mimic the wear and tear that occurs naturally over time.

-

Patination: Some artisans use patination techniques to create an aged look on stainless steel. This involves applying various substances to the surface, such as chemicals or heat, to induce oxidation and develop a specific color or finish.

3.Coloring and Finishing: After the desired texture and pattern are achieved, additional steps may be taken to enhance the antique appearance. This could involve applying heat to the surface to develop specific colors, or using dyes or pigments to add depth and variation to the finish.

4.Sealing and Protection: Once the desired antique effect is achieved, the stainless steel sheets may be sealed with a protective coating to prevent further oxidation and to maintain the appearance over time.

5.Quality Control and Inspection: Finally, the antique stainless steel sheets undergo thorough quality control and inspection to ensure that they meet the desired standards for appearance, durability, and performance.

Overall, the process of making antique stainless steel sheets involves a combination of chemical treatments, mechanical distressing, coloring techniques, and protective coatings to achieve the desired aged or antique appearance while maintaining the durability and corrosion resistance of stainless steel.

Application:

What services Hermes steel can offer to you?

R & D Experience: Have strong research and development capabilities to develop new products, and technologies, or improve existing products, technologies, or processes through experimentation and research.

Quality Inspection Service: A process in place for inspecting products, components, or materials to ensure that they conform to specified quality standards.

Packaging Service: With packaging service, we can accept customized outer packaging design

Good after-sales service: Have a professional after-sales service team to follow up on your order in real time to ensure that customers are satisfied throughout the shopping process.

Products Customized Service: Material / Style / Size / Color / Process / Function

Customization Sheet Metal Service: Sheet Blade Cutting / Laser Cutting / Sheet Grooving / Sheet Bending / Sheet Welding / Sheet Polishing

FAQ:

1、What is antique brass stainless steel?

-Antique brass stainless steel is a type of stainless steel material that has been specially treated to mimic the appearance of antique brass while retaining the durability of stainless steel.

2、How is it produced?

-The production process typically involves applying a special chemical treatment or coating to the surface of stainless steel to achieve the desired antique brass appearance.

3、What are the uses of antique brass stainless steel?

-Antique brass stainless steel can be used for various applications including interior and exterior decoration, furniture making, architectural embellishments, kitchenware, and more, offering a combination of vintage aesthetics and stainless steel durability.

4、How does it differ from real brass?

Unlike real brass, antique brass stainless steel offers enhanced corrosion resistance and durability, requiring less maintenance over time. Additionally, it tends to be more affordable compared to solid brass.

5、How do you clean and maintain antique brass stainless steel?

-Cleaning antique brass stainless steel typically involves using mild soap and water with a soft cloth. Avoid abrasive or acidic cleaners that may damage the surface treatment.

6、What is the durability of antique brass stainless steel?

-Antique brass stainless steel shares the corrosion resistance and durability characteristics of standard stainless steel, providing long-lasting performance in various environments.

7、What is the price range of antique brass stainless steel?

-The price of antique brass stainless steel can vary depending on factors such as thickness, size, surface treatment, and market demand. Generally, it is more affordable than solid brass but may be slightly higher priced than standard stainless steel.

8、Is antique brass stainless steel customizable?

-Manufacturers often offer customization options for antique brass stainless steel, allowing customers to specify thickness, size, surface treatment, and texture according to their project requirements.

9、Where can antique brass stainless steel be used in design?

-Antique brass stainless steel can be used in a variety of design applications to achieve vintage or industrial aesthetics, including architectural facades, interior décor, furniture design, and more.

10、Are there any environmental considerations?

-Antique brass stainless steel typically does not contain harmful substances and, being stainless steel, is recyclable, offering environmental benefits compared to some other materials.

Post time: Mar-19-2024