What Is Mirror Stainless Steel Sheet?

A mirror stainless steel sheet is a type of sheet metal that has undergone a highly polished and buffed finishing process, resulting in a reflective surface that resembles a mirror. It is also commonly referred to as a mirror finish stainless steel sheet. This type of finish is popular for its aesthetic appeal, high reflectivity, and smooth surface.

Features of Mirror Stainless Steel Sheets:

1. High Reflectivity: Mirror stainless steel sheets have excellent reflective properties, making them ideal for decorative applications and surfaces where a bright and shiny appearance is desired.

2. Smooth Surface:The polishing process used for mirror stainless steel sheets ensures a smooth, flawless surface without visible scratches or imperfections.

3. Corrosion Resistance:Like other stainless steel grades, mirror stainless steel sheets offer good corrosion resistance due to their high chromium content.

4. Variety of Applications: Mirror stainless steel sheets are commonly used in architectural, interior design, automotive, and decorative applications. They can be found in elevator interiors, wall claddings, countertops, decorative panels, and more.

Surface Protection:

The highly polished surface of mirror stainless steel sheets is susceptible to scratches and fingerprints. To protect the surface during handling, transportation, and installation, manufacturers often apply a protective film. This film can be peeled off after the product is installed to reveal the pristine mirror finish.

Grade of Stainless Steel:

Mirror stainless steel sheets are available in various grades of stainless steel, such as 304, 316, and others. The grade chosen depends on the specific application and the desired level of corrosion resistance.

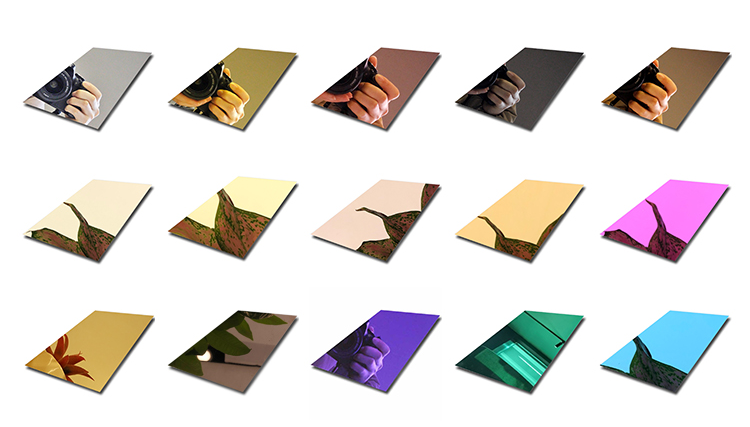

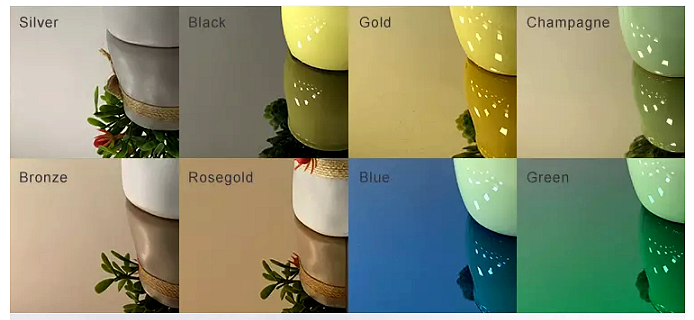

Color Options For Mirror Finish Stainless Steel Sheet

There is a wide range of color options for mirror finish stainless sheets, which can provide different visual effects for different requirements. All of them can improve your project with valuable properties, such as appealing aesthetics, resistance to rust and corrosion, longevity, and so on. The surface of mirror stainless steel sheets is finished with BA, 2B polish also known as #8, it comes with high gloss and reflectivity to bring the interior or exterior space a unique visual experience.

Features and Applications:

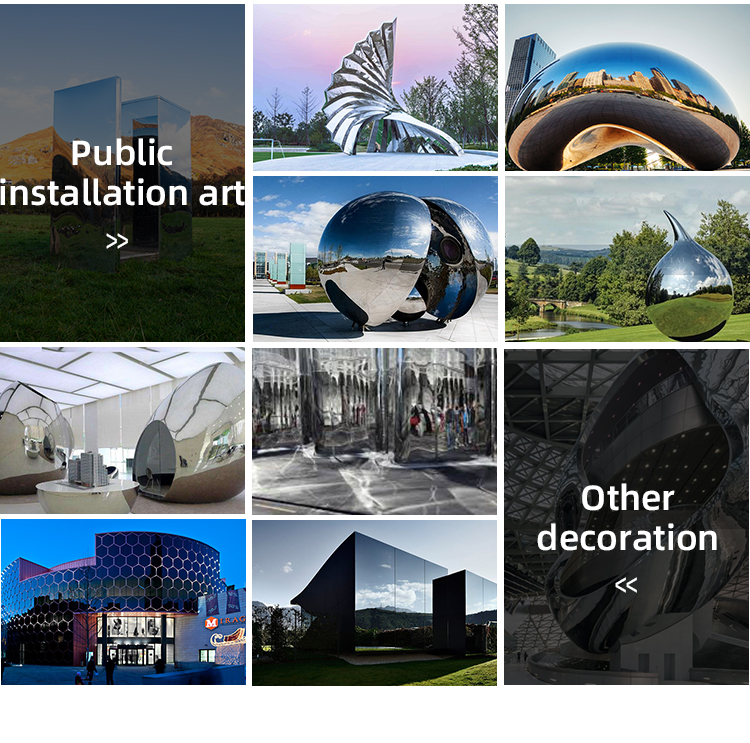

- Mirror stainless steel sheets are known for their excellent aesthetic appeal due to their highly reflective surface, which resembles a mirror. The reflective finish adds a luxurious and modern touch to various applications.

- They are commonly used in architectural and interior design projects, including wall cladding, decorative panels, elevator doors, and furniture accents.

- Mirror stainless steel sheets are also used in automotive applications, such as trim pieces and accessories, for their stylish appearance.

- In the food and beverage industry, mirror stainless steel is used for decorative purposes, such as on countertops, backsplashes, and fixtures.

- Due to their durability and corrosion resistance, mirror stainless steel sheets can be used in exterior applications as well.

Polishing Methods:

The polishing process used to create mirror stainless steel sheets is typically a multi-step procedure involving progressively finer abrasives. Different manufacturers or fabricators may have slightly different processes, but the basic steps include grinding and sanding the stainless steel surface with abrasive belts or papers of increasing fineness until a smooth, scratch-free surface is achieved. This is followed by a final buffing stage using polishing compounds or abrasive pads to enhance the reflectivity and shine of the surface.

Materials you’ll need:

1. Stainless steel workpiece

2. Safety gear (safety goggles, dust mask, gloves)

3. Sandpaper (grits from coarse to fine, e.g., 80, 120, 220, 400, 600, 800, 1000)

4. Orbital sander or sanding blocks

5. Stainless steel polishing compound

6. Soft cotton cloths or polishing pads

7. Microfiber cloth

Step 1: Safety first

Ensure you’re working in a well-ventilated area and wear safety gear to protect yourself from dust and debris.

Step 2: Prepare the workpiece

Clean the stainless steel surface thoroughly to remove any dirt, grease, or contaminants that could interfere with the sanding process.

Step 3: Coarse sanding

Start with the lowest grit sandpaper (e.g., 80) and use an orbital sander or sanding block to sand the entire surface of the stainless steel. Keep the sandpaper flat and move in straight lines, going with the grain of the steel. This step will remove any visible scratches or imperfections on the surface.

Step 4: Progress through grits

Gradually work your way up through the grits of sandpaper, from medium (e.g., 120, 220) to fine (e.g., 400, 600, 800, 1000). Each time you change grit, make sure to remove the previous grit’s scratches by sanding in a perpendicular direction to the previous sanding lines. This process is known as “cross-hatching.”

Step 5: Finer sanding

As you approach the higher grits, the scratches will become less visible. The goal is to achieve a smooth and uniform surface. Be patient and ensure you’ve removed all the scratches from the previous grit before moving on.

Step 6: Buffing and polishing

Now that the surface is smooth and scratches are minimal, it’s time to use the stainless steel polishing compound. Apply a small amount of the compound to a soft cotton cloth or polishing pad and work it into the steel using circular motions. Continue polishing until you achieve a bright and reflective surface.

Step 7: Final polishing

For the mirror finish, you can take it one step further by using a microfiber cloth and continuing to polish the surface with the polishing compound. This will enhance the shine and bring out the mirror-like effect.

Step 8: Clean the surface

Once you’re satisfied with the mirror finish, clean the surface thoroughly to remove any residue from the polishing compound. Use a clean microfiber cloth to give it a final wipe down.

Maintenance:

While mirror stainless steel sheets are visually stunning, they can show fingerprints, smudges, and scratches more easily than other finishes. Regular cleaning with mild soap and water, followed by a gentle wipe-down with a microfiber cloth, can help maintain their appearance.

Conclusion

There are many reasons to choose stainless steel mirror sheet for your next project. These metals are durable, beautiful, and versatile. With so many potential applications, these sheets are sure to add a touch of elegance to any space.Contact HERMES STEEL today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs.Please feel free to CONTACT US !

Post time: Jul-26-2023