Etching Stainless steel plates inzira inoshandisa kemikari nzira kugadzira mapatani kana zvinyorwa pamusoro pesimbi isina tsvina. Iyi nzira inowanzo shandiswa pakushongedza, zvikwangwani, uye akasiyana maindasitiri ekushandisa. Pazasi pane ruzivo rwakadzama nezve etching Stainless simbi ndiro:

Nheyo dzekutanga dzeEtching Stainless Steel Plates

Musimboti wakakosha wekupinza simbi isina tsvina ndeye kushandisa makemikari ejenti (kazhinji maasidhi kana mabhesi) kubvisa zvikamu zvepasi pesimbi isina tsvina kugadzira mapatani chaiwo kana zvinyorwa. Iyo etching process inowanzo sanganisira anotevera matanho:

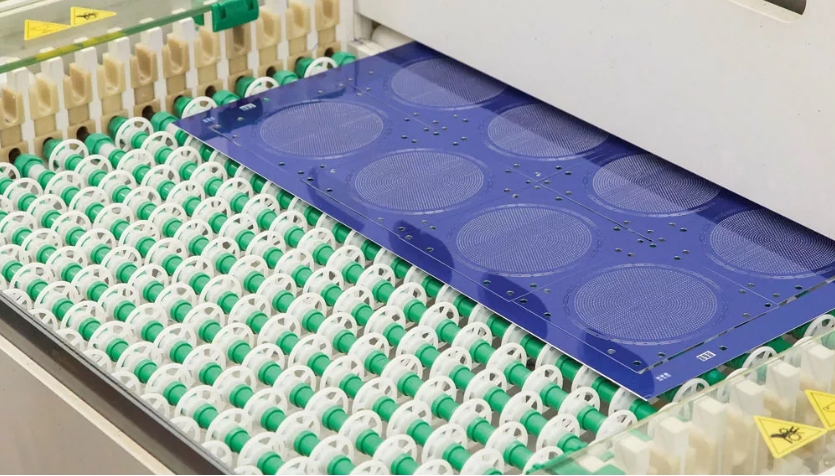

Kugadzirira Kwepamusoro: Kuchenesa nzvimbo yesimbi isina tsvina kubvisa girisi, oxide layer, uye zvimwe zvinosvibisa.

Kupfekedza Resist Layer: Kuisa dhizaini yezvidziviriro, senge photoresist kana zvimwe zvinhu zvinodzivirira kemikari, kunzvimbo yesimbi isina tsvina.

Kuratidzwa uye Kubudirira: Kuendesa iyo pateni pane yekuramba layer kuburikidza nephotolithography kana dzimwe nzira, uye nekuigadzira kuti ibudise pachena zvikamu zvinoiswa.

Etching: Kunyudza kana kupfapfaidza ndiro yesimbi isina tsvina ine etching solution, iyo inoshatisa zvikamu zviri pachena zvesimbi isina tsvina.

Kubvisa Resist Layer: Kusuka iyo yakasara yekuramba layer, ichisiya kumashure etched mapatani kana zvinyorwa.

Common Etching Nzira

1, Chemical Etching: Kushandisa asidhi (yakadai se nitric acid kana hydrofluoric acid) kana base (senge sodium hydroxide) mhinduro dze etching. Iyi ndiyo yakajairika etching nzira uye yakakodzera kune akawanda Stainless simbi zvinhu.

2, Electrochemical Etching: Kushandisa electrochemical reactions kuti uwane etching. Iyi nzira yakanyatsojeka uye yakakodzera kune yakakwirira-chaiyo etching basa.

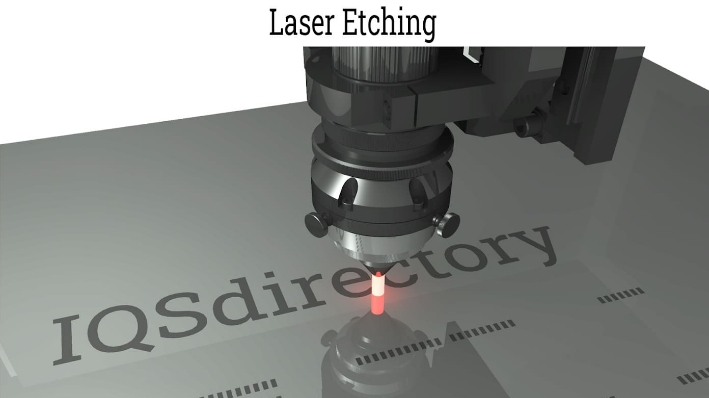

3, Laser Etching: Kushandisa high-energy laser beam kuti zvakananga ablate mapatani pamusoro Stainless simbi pamusoro. Laser etching haidi makemikari ejenti uye yakakodzera kune yakaoma uye yakanaka mapatani.

Zvishandiso zveStainless Steel Etching

Decoration: Inoshandiswa mukushongedza kwezvivakwa, kushongedzwa kwemba, mabasa emifananidzo, nezvimwe, kugadzira maitiro akanaka uye maumbirwo.

Signage uye Nameplates: Inoshandiswa kugadzira akasiyana masisitimu, nameplates, mavara, nezvimwewo, ichipa hunogara hwekuzivikanwa mhinduro.

Industrial Applications: Inoshandiswa kugadzira chaiyo zvikamu, mafirita, magridi, uye zvimwe zvikamu zveindasitiri.

Zvakanakira uye Zvakaipa Etching Stainless Simbi

Zvakanakira:

- High Precision: Inokwanisa kugadzira yakanaka uye yakaoma mapatani uye zvinyorwa.

- Durability: Etched mapatani anodzivirira kupfeka uye kusagadzikana-kuora.

- Kuchinja-chinja: Inoshanda kune akasiyana simbi isina tsvina zvinhu uye ukobvu.

Zvakaipa:

- Matambudziko Ezvakatipoteredza: Chemical etching inoburitsa tsvina asidhi, mabhesi, uye zvimwe zvinosvibisa zvinoda kuraswa zvakakodzera.

- High Cost: Kunyanya kune diki-batch tsika kugadzirwa, mutengo unogona kunge wakakwira.

- Nguva Yakareba Yokugadzirisa: Iyo etching process inogona kutora nguva, kunyanya kune yakaoma mapatani.

Zvimwe zve etching Stainless simbi sheet pateni

Zvekungwaririra

- Matanho Okuchengetedza: Matanho ekudzivirira anofanirwa kutorwa panguva yekucheka kudzivirira kukuvadzwa kubva kumakemikari ejenti kune vanhu uye nharaunda.

-

Surface Treatment: Ita shuwa kuti simbi isina tsvina yakachena isati yaiswa kuti ivimbise iyo etching maitiro.

-

Pattern Design: Iyo pateni dhizaini inofanirwa kufunga nezve hunhu hwe etching process kudzivirira zvakanyanyisa kuomarara zvigadziriso izvo zvinogona kutungamira mukutadza kwe etching.

Nesumo iri pamusoro, iwe unofanirwa kuve nekunzwisisa kwakawanda kweiyo etching maitiro eStainless simbi ndiro. Kana iwe uine mimwe mibvunzo yakananga kana uchida yakadzama nhanho-nhanho nhungamiro kanatora mahara samples, unogonasunungukai kutibvunza.

Nguva yekutumira: May-24-2024