Stainless steel embossing sheet is a concave and convex pattern on the surface of the steel plate, which is used for the place where the finish and appreciation are required. Embossed rolling is rolled with a pattern of work roller, the work roller is usually processed with erosion liquid, the depth of the bump on the plate varies according to the pattern, about 20-30 microns.

Grade and sizes:

The main materials are 201, 202, 304, 316 and other stainless steel plates, and the general specifications and sizes are: 1000*2000mm, 1219*2438mm, 1219*3048mm; it can be undetermined or embossed in a whole roll, with a thickness of 0.3mm~2.0mm.

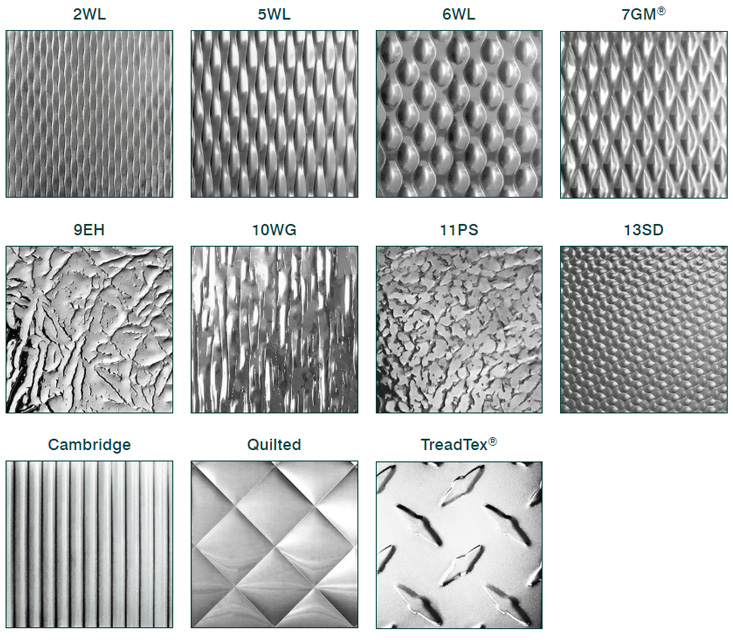

Classification:

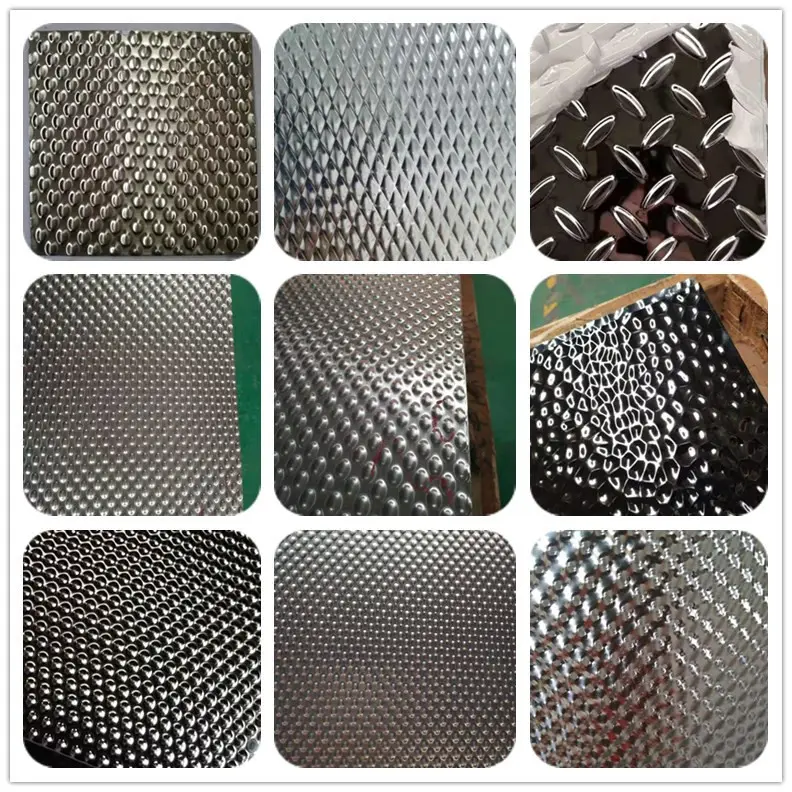

Pearl board, small square pattern, diamond square pattern, antique square pattern, twill pattern, chrysanthemum pattern, ice bamboo pattern, sand board, cube, free pattern, stone pattern, butterfly flower, woven bamboo pattern, small diamond, large oval, panda pattern, European pattern, Ingot, linen pattern, large water beads, Mosaic, wood pattern, swastika flower, Wanfu Linmen, Ruyi cloud, square pattern, color pattern, color circle pattern.

Advantages of stainless steel embossed plate:

Main advantages: good-looking, durable, wear-resistant, strong decorative effect. Visually beautiful, high-quality, easy to clean, maintenance-free, resistant to impact, pressure, scratches and no fingerprints.

Application of stainless steel embossed plate:

Stainless steel embossing sheet is suitable for decorating elevator car, subway car, all kinds of cabin, architectural decoration, metal curtain wall industry.

Embossed stainless steel sheets are stainless steel plates or sheets that have undergone a process called embossing. Embossing is a metalworking technique in which a pattern or design is impressed onto the surface of the metal sheet, creating a three-dimensional relief. The resulting textured surface adds both aesthetic appeal and functional benefits to the stainless steel sheets.

Here’s how the embossing process typically works:

1. Stainless Steel Sheet Selection: The process begins with selecting the appropriate stainless steel sheet. Stainless steel is chosen for its durability, corrosion resistance, and overall aesthetic appearance.

2. Design Selection: A design or pattern is chosen for the embossing process. There are various patterns available, ranging from simple geometric shapes to intricate textures.

3. Surface Preparation: The stainless steel sheet’s surface is thoroughly cleaned to remove any dirt, oils, or contaminants that could interfere with the embossing process.

4. Embossing: The cleaned stainless steel sheet is then placed between embossing rollers, which apply pressure and create the desired pattern on the sheet’s surface. The embossing rollers have the pattern engraved on them, and they transfer the pattern to the metal as it passes through.

5. Heat Treatment (Optional): In some cases, after embossing, the stainless steel sheet may undergo a heat treatment process to stabilize the metal’s structure and relieve any stresses created during embossing.

6. Trimming and Cutting: Once embossing is complete, the stainless steel sheet may be trimmed or cut to the desired size or shape.

Conclusion

There are many reasons to choose stainless steel embossed sheet for your next project. These metals are durable, beautiful, and versatile. With so many potential applications, these sheets are sure to add a touch of elegance to any space.Contact HERMES STEEL today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs.Please feel free to CONTACT US !

Post time: Jul-21-2023