Etching stainless steel sheets is a process that uses chemical methods to create patterns or text on the surface of stainless steel plates. This process is commonly used for decoration, signage, and various industrial applications. Below is some detailed knowledge about etching stainless steel plates:

Basic Principles of Etching Stainless Steel Sheets

The basic principle of etching stainless steel sheets is to use chemical agents (typically acids or bases) to remove parts of the stainless steel surface to form specific patterns or text. The etching process usually includes the following steps:

- Surface Preparation: Cleaning the stainless steel surface to remove grease, oxide layers, and other contaminants.

- Coating the Resist Layer: Applying a layer of resist material, such as photoresist or other chemically resistant material, to the stainless steel surface.

- Exposure and Development: Transferring the pattern onto the resist layer through photolithography or other methods, and developing it to expose the parts to be etched.

- Etching: Immersing or spraying the stainless steel plate with an etching solution, which corrodes the exposed parts of the stainless steel.

- Removing the Resist Layer: Washing off the remaining resist layer, leaving behind the etched patterns or text.

Common Etching Methods

- Chemical Etching: Using acid (such as nitric acid or hydrofluoric acid) or base (such as sodium hydroxide) solutions for etching. This is the most common etching method and is suitable for most stainless steel materials.

- Electrochemical Etching: Using electrochemical reactions to achieve etching. This method is more precise and suitable for high-precision etching work.

- Laser Etching: Using a high-energy laser beam to directly ablate patterns on the stainless steel surface. Laser etching does not require chemical agents and is suitable for complex and fine patterns.

Applications of Stainless Steel Etching

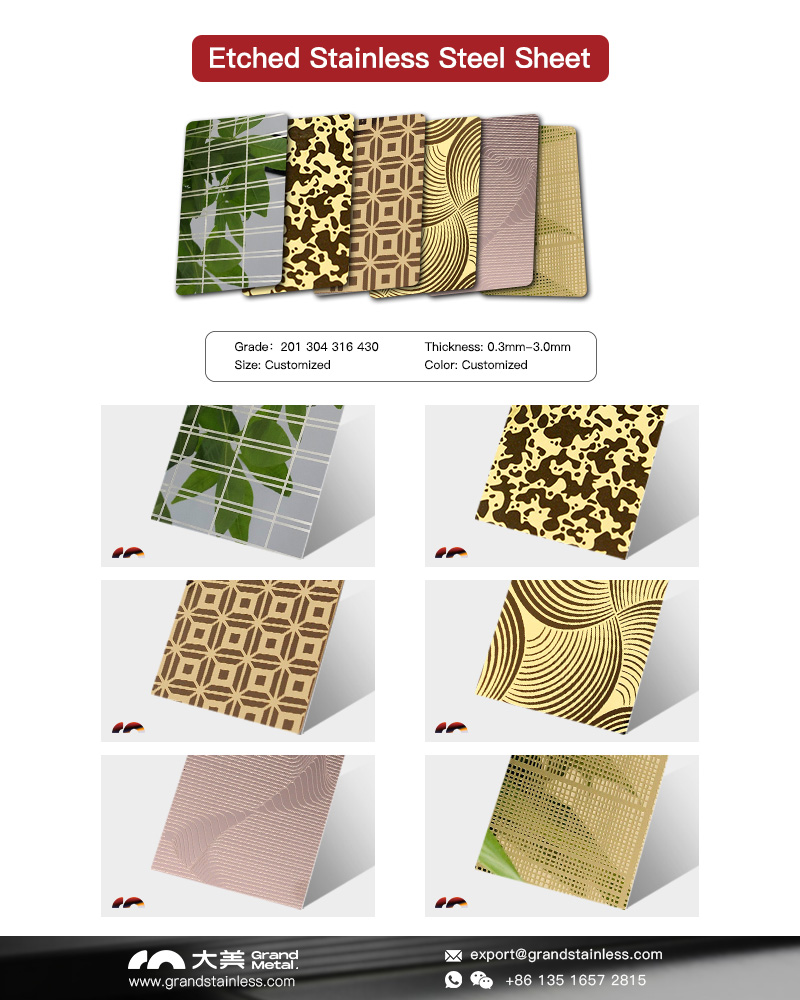

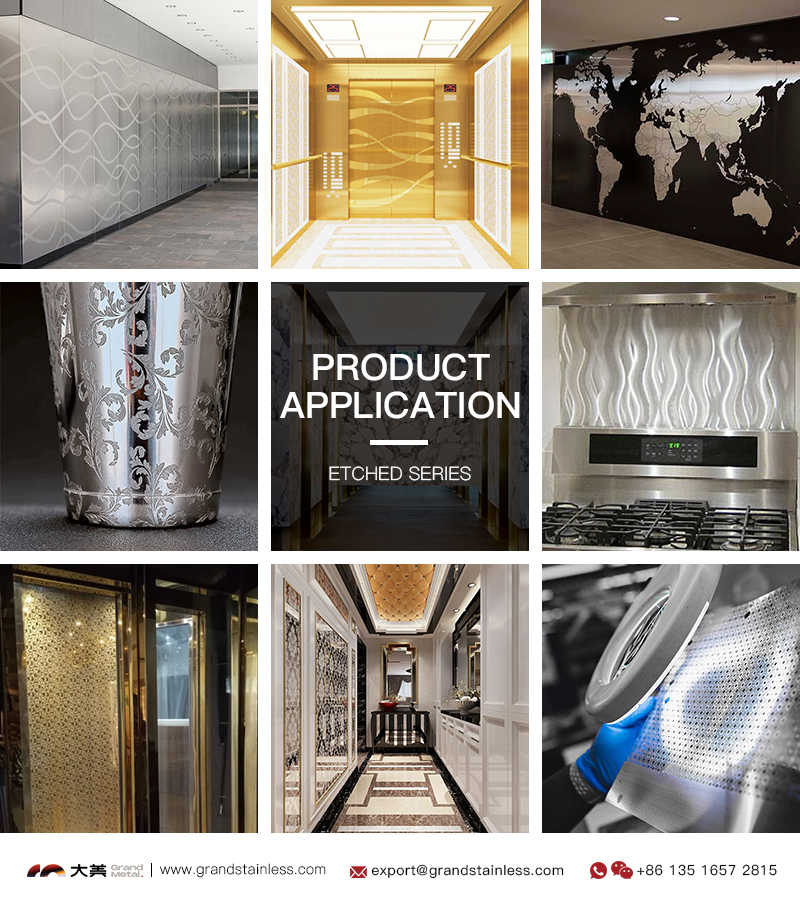

- Decoration: Used in architectural decoration, home decoration, artworks, etc., to create exquisite patterns and textures.

- Signage and Nameplates: Used to manufacture various signs, nameplates, labels, etc., providing durable identification solutions.

- Industrial Applications: Used to manufacture precision parts, filters, grids, and other industrial components.

Advantages and Disadvantages of Etching Stainless Steel

Advantages:

- High Precision: Capable of producing fine and complex patterns and text.

- Durability: Etched patterns are wear-resistant and corrosion-resistant.

- Flexibility: Applicable to various stainless steel materials and thicknesses.

Disadvantages:

- Environmental Issues: Chemical etching produces waste acids, bases, and other pollutants that need proper disposal.

- High Cost: Especially for small-batch custom production, the cost can be high.

- Long Processing Time: The etching process can be time-consuming, especially for complex patterns.

Precautions

- Safety Measures: Protective measures should be taken during etching to avoid harm from chemical agents to people and the environment.

- Surface Treatment: Ensure the stainless steel surface is clean before etching to guarantee the etching effect.

- Pattern Design: The pattern design should consider the characteristics of the etching process to avoid overly complex designs that may lead to etching failure.

With the above introduction, you should have a more comprehensive understanding of the etching process for stainless steel plates. If you have more specific questions or need detailed step-by-step guidance, you can further refer to relevant technical materials or consult us!

Post time: Aug-10-2024