What are stainless steel mirror sheets?

Stainless steel mirror sheets are sheets of stainless steel that have undergone a specialized finishing process to achieve a highly reflective and mirror-like surface. These sheets are typically made from stainless steel alloys, which are known for their corrosion resistance, strength, and durability. The mirror finish is achieved through polishing and buffing processes that create a smooth, reflective surface.

The features of stainless steel mirror sheets

-

Material Composition:

- Stainless steel mirror sheets are commonly made from austenitic stainless steel grades such as 304 or 316. These grades contain chromium and nickel, which contribute to corrosion resistance and the ability to achieve a high polish.

-

Mirror Finish:

- The mirror finish is attained through a multi-step process. Initially, the stainless steel undergoes mechanical grinding to remove any imperfections or irregularities on the surface. Subsequent stages involve finer abrasives, polishing compounds, and buffing wheels to achieve a reflective, mirror-like appearance.

-

Applications:

- Stainless steel mirror sheets find applications in various industries and contexts. They are commonly used in architectural design, interior decoration, automotive detailing, kitchen appliances, reflective signage, and other decorative elements where a polished and reflective surface is desired.

-

Aesthetics and Versatility:

- The mirror finish on these sheets provides a sleek and modern aesthetic. Stainless steel mirror sheets are versatile and can be incorporated into different design styles, ranging from contemporary to more traditional applications.

-

Corrosion Resistance:

- Stainless steel inherently possesses corrosion-resistant properties. This makes mirror sheets suitable for use in environments where exposure to moisture, chemicals, or outdoor elements could otherwise degrade the material.

-

Hygienic Properties:

- The smooth and non-porous surface of stainless steel mirror sheets makes them easy to clean and maintain. This is particularly advantageous in applications where hygiene and cleanliness are crucial, such as in the food industry or healthcare settings.

-

Customization:

- Stainless steel mirror sheets can be further customized to achieve specific design effects. Additional treatments, such as PVD (Physical Vapor Deposition) coating, brushing, etching, and stamping, can be applied to create unique textures, colors, or patterns.

Applications of stainless steel mirror sheets in different industries

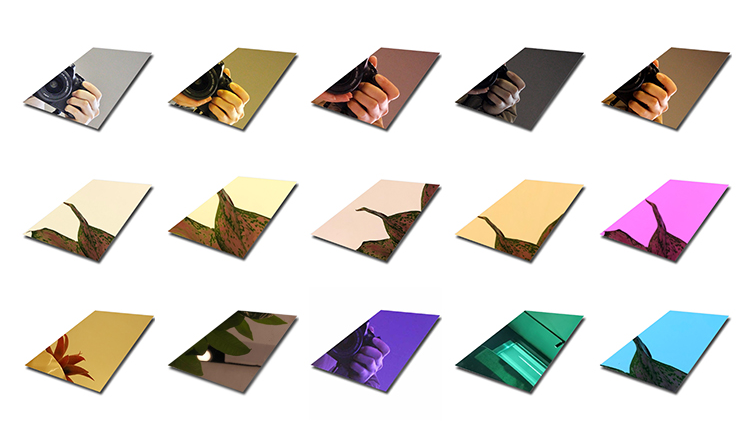

The stainless steel mirror sheet is very versatile in our lives for architectural and decorative applications. it can also be combined with other surface finishes adding color and creativity to our living space, such as PVD coating, brushing, sandblasting, etching, and stamping.

Mirror

- Stainless steel mirror sheets are sheets of stainless steel that have undergone a specialized finishing process to achieve a highly reflective and mirror-like surface. These sheets are typically made from austenitic stainless steel, such as grades 304 or 316, which are known for their corrosion resistance and durability.

Mirror+PVD Coating (Physical Vapor Deposition):

- PVD coating involves the deposition of a thin film onto the stainless steel surface, adding color and improving wear resistance. This process allows for various colors, including gold, rose gold, black, and other metallic shades.

Mirror+Brushing:

- Brushing the stainless steel surface creates a textured finish with a series of parallel lines. This finish adds a contemporary and distinctive look to the mirror sheet.

Mirror+Sandblasting:

- Sandblasting involves propelling fine particles at high speed onto the stainless steel surface, creating a textured or frosted appearance. This technique can be used to add depth and visual interest to the mirror sheet.

Mirror+Etching:

- Etching involves chemically treating the surface of the stainless steel to create patterns, designs, or textures. This can be a precise and artistic way to add decorative elements to mirror sheets.

Mirror+Stamping:

- Stamping is a process where patterns or designs are pressed into the surface of the stainless steel using a die. This method can be used to create intricate and repetitive designs.

By combining stainless steel mirror sheets with these surface finishes and treatments, architects, designers, and manufacturers can achieve a wide range of aesthetic effects, making these materials suitable for diverse applications in interior design, architecture, and decorative arts. This flexibility in design options allows for customization and creation of distinctive and visually striking spaces.

Specification and Thickness for Selection

A variety of thicknesses and sizes are available to match a wide range of projects. Stainless steel mirror sheets are also available in standard widths and lengths.

Width:

1000 / 1219 / 1500mm or Custom-made 39″ / 48″ / 59

Length:

2438 / 3048 / 4000mm or Custom-made 96″/ 120″/ 157

Thickness:

0.3mm~3mm(11ga~26ga)

Conclusion

Overall, mirror stainless steel sheets have a wide range of applications in many different industries. Thanks for reading! We hope this article was informative and helpful. if you have any questions of the mirror stainless steel sheet, please free feel to contact us.

Post time: Dec-28-2023