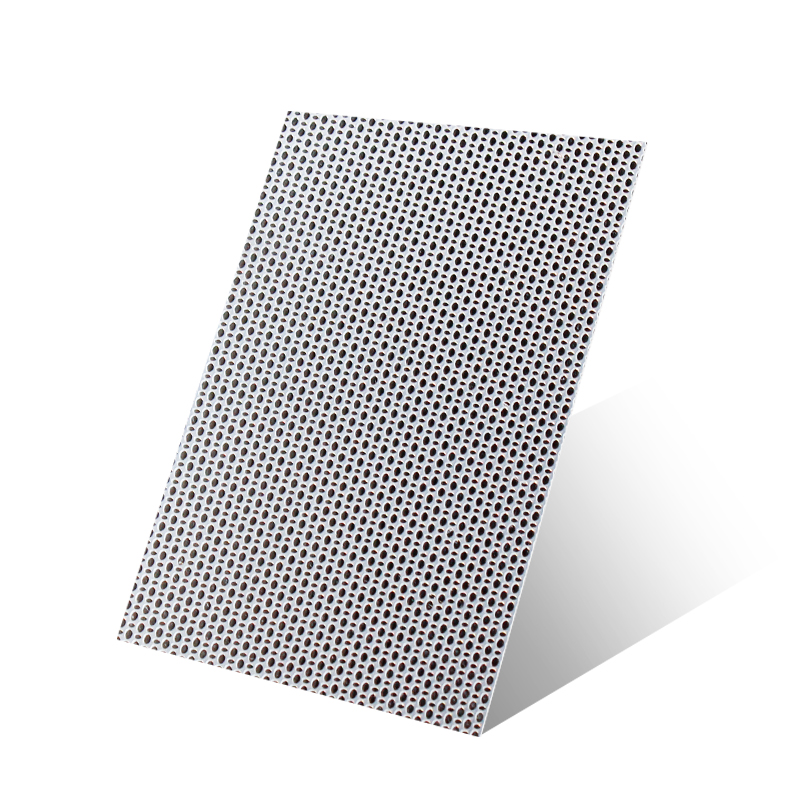

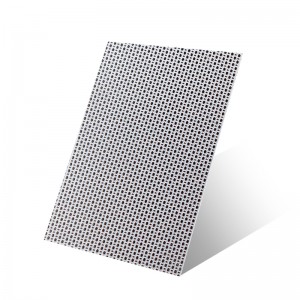

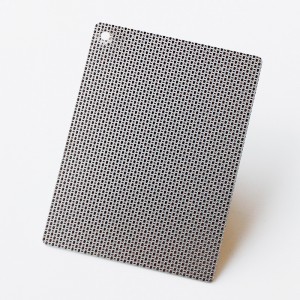

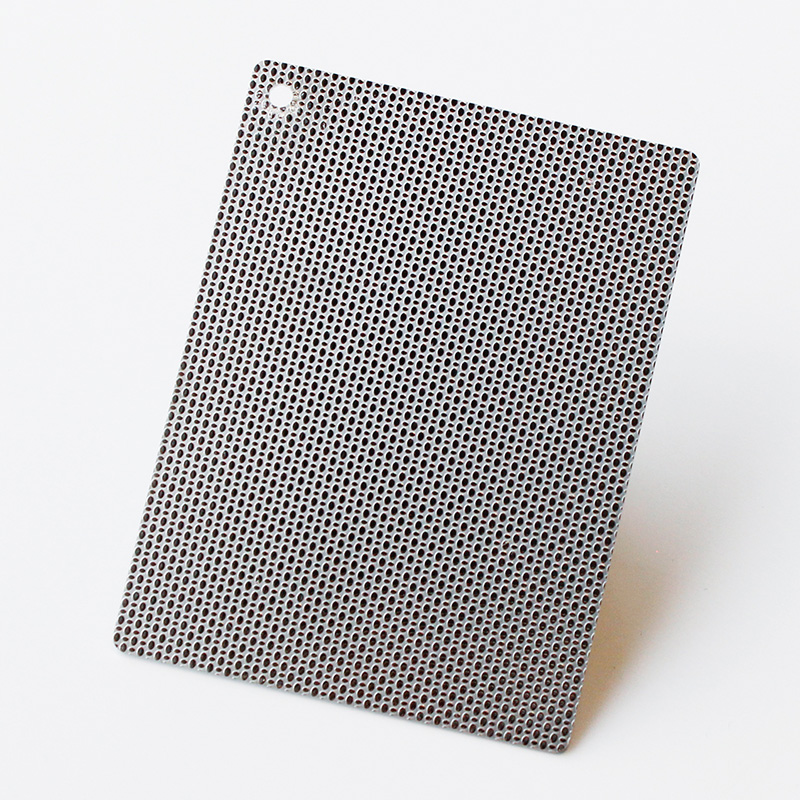

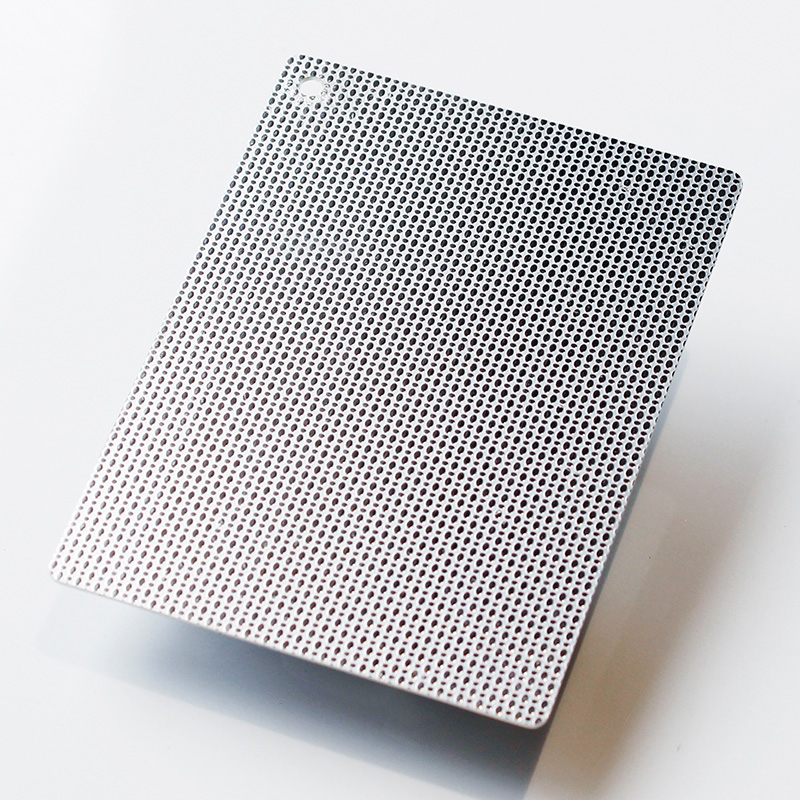

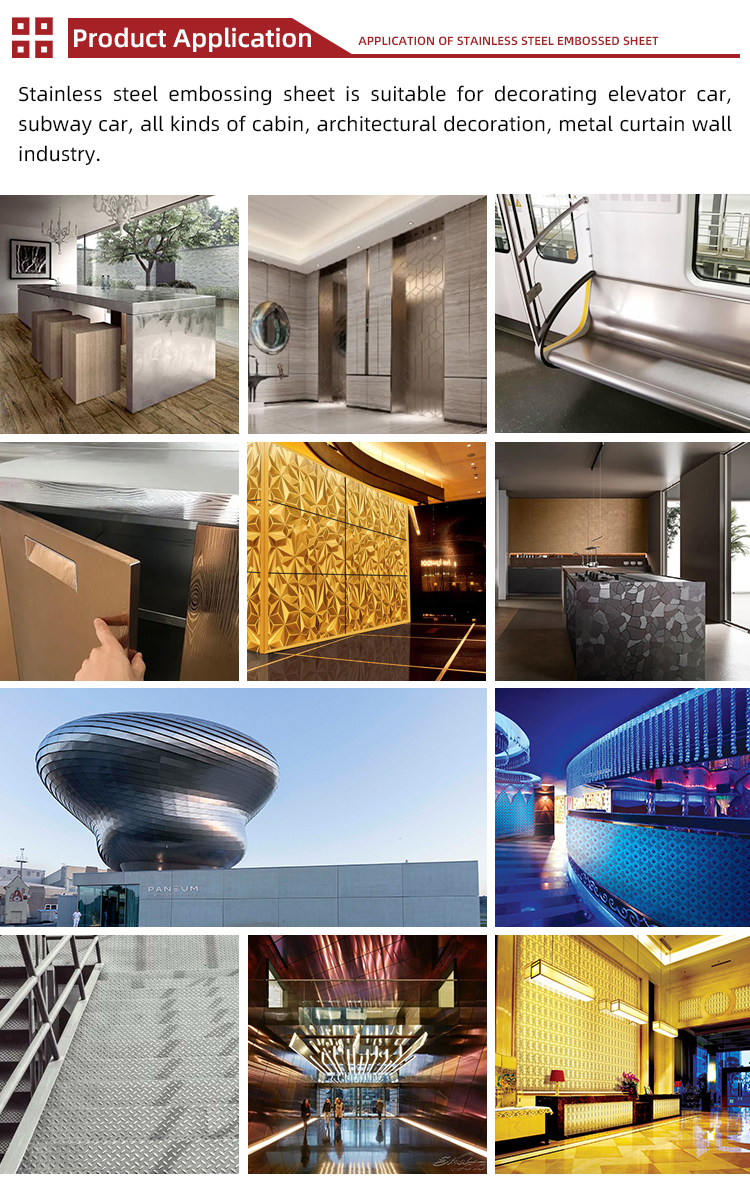

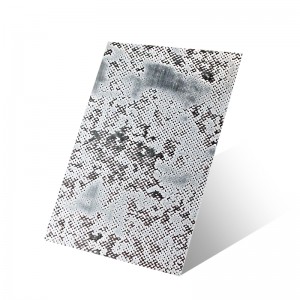

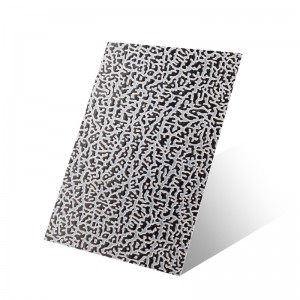

4*8 ft Small Linen Pattern Embossed Stainless Steel Sheet – Hermes steel

What is the embossed stainless steel sheet?

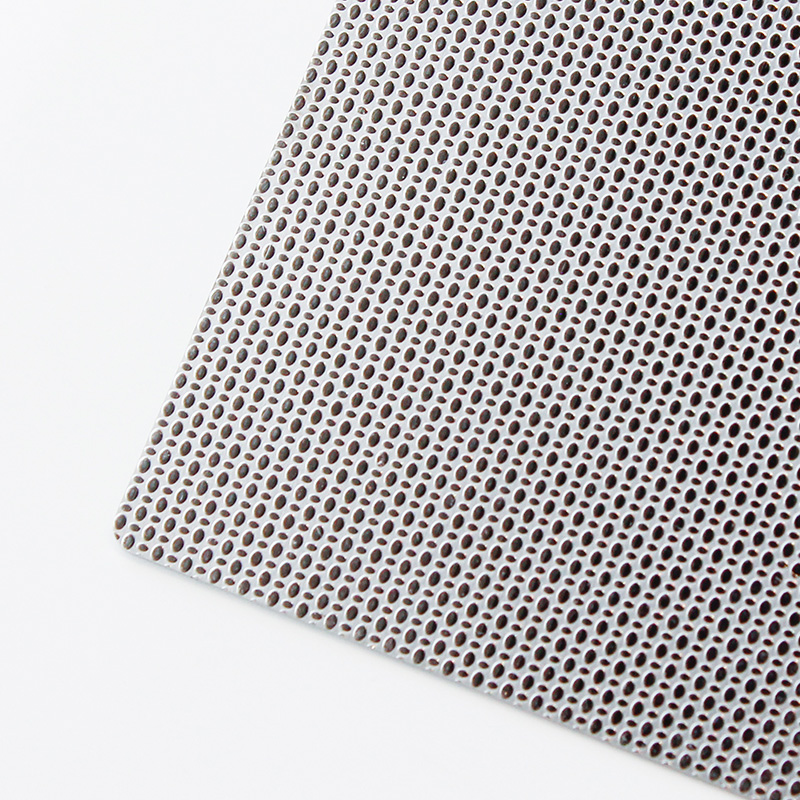

Embossed stainless steel sheet is a type of stainless steel sheet that has undergone an embossing process on its surface. This process involves applying pressure and heat to the stainless steel surface, creating raised or textured patterns, designs, or images on the surface.

*What is embossing?

Embossing is a decorative technique used to create a raised, three-dimensional design on a surface, typically on paper, cardstock, metal, or other materials. The process involves pressing a design or pattern into the material, leaving a raised impression on one side and a corresponding recessed impression on the other side.

There are two main types of embossing:

1. Dry Embossing: In this method, a stencil or template with the desired design is placed on top of the material, and pressure is applied using an embossing tool or stylus. The pressure forces the material to deform and take the shape of the stencil, creating a raised design on the front side.

2. Heat Embossing: This technique involves the use of special embossing powders and a heat source, such as a heat gun. First, a stamped image or design is created on the material using embossing ink, which is a slow-drying and sticky ink. Embossing powder is then sprinkled over the wet ink, sticking to it. Excess powder is shaken off, leaving only the powder adhered to the stamped design. The heat gun is then applied to melt the embossing powder, resulting in a raised, glossy, and embossed effect.

|

Type

|

Small Linen Pattern Embossed Stainless Steel Sheet |

|

Thickness

|

0.3 mm - 3.0 mm

|

|

Size

|

1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max. width 1500mm

|

|

SS Grade

|

304,316, 201,430, etc.

|

|

Finish

|

Embossed

|

|

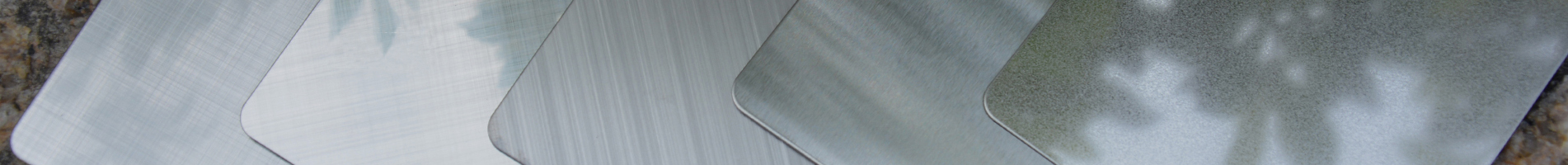

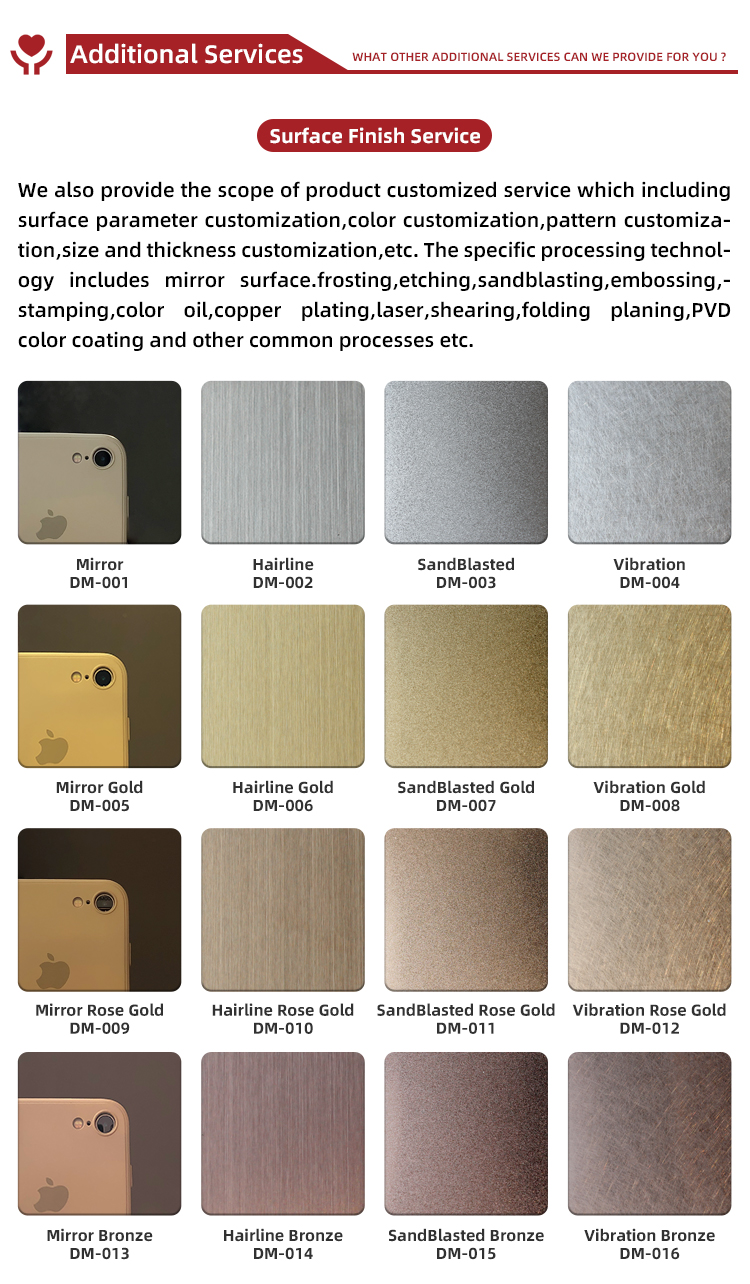

Available finishes

|

No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc.

|

|

Origin

|

POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc.

|

|

Packing way

|

PVC+ waterproof paper + strong sea-worthy wooden package

|

Advantages:

1. The lower the thickness of the sheet the more beautiful and efficient

2. Embossing increases the strength of the material

3. It makes the surface of the material scratch-free

4. Some embossing gives a tactile finish appearance.

Grade and sizes:

The main materials are 201, 202, 304, 316, and other stainless steel plates, and the general specifications and sizes are: 1000*2000mm, 1219*2438mm, and 1219*3048mm; it can be undetermined or embossed in a whole roll, with a thickness of 0.3mm~2.0mm.

How the embossing process typically works:

1. Stainless Steel Sheet Selection: The process begins with selecting the appropriate stainless steel sheet. Stainless steel is chosen for its durability, corrosion resistance, and overall aesthetic appearance.

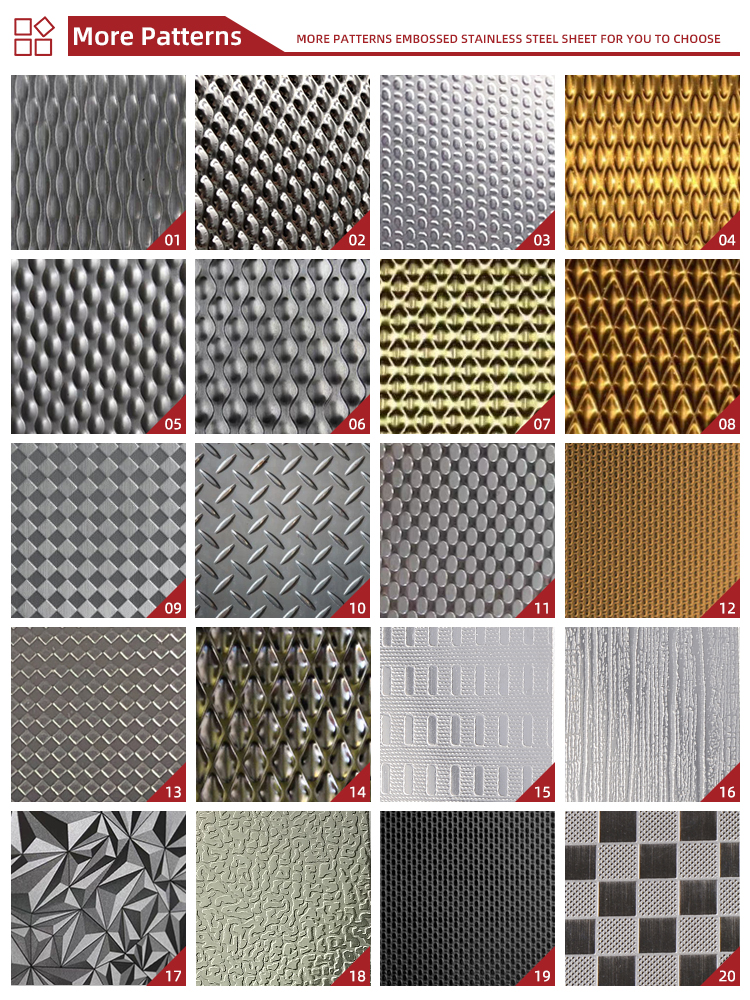

2. Design Selection: A design or pattern is chosen for the embossing process. There are various patterns available, ranging from simple geometric shapes to intricate textures.

3. Surface Preparation: The stainless steel sheet’s surface is thoroughly cleaned to remove any dirt, oils, or contaminants that could interfere with the embossing process.

4. Embossing: The cleaned stainless steel sheet is then placed between embossing rollers, which apply pressure and create the desired pattern on the sheet’s surface. The embossing rollers have the pattern engraved on them, and they transfer the pattern to the metal as it passes through.

5. Heat Treatment (Optional): In some cases, after embossing, the stainless steel sheet may undergo a heat treatment process to stabilize the metal’s structure and relieve any stresses created during embossing.

6. Trimming and Cutting: Once embossing is complete, the stainless steel sheet may be trimmed or cut to the desired size or shape.

Foshan Hermes Steel Co., Limited, establishes a large stainless steel comprehensive service platform integrating international trading, processing, storage and after-sales service.

Our company is located in Foshan Liyuan Metal Trading Center, which is a large stainless steel distribution and trading area in southern China, with convenient transportation and mature industrial supporting facilities. A lot of merchants gathered around the market center. Combining the advantages of market location with strong technologies and scales of major steel mills, Hermes Steel takes full advantages in the field of distribution and quickly shares market information. After more than 10 years of unremitting operation, Hermes Steel establishes professional teams of international trading, large warehousing, processing and after-sales service, providing professional stainless steel import and export trading services to our international customers with fast response, stable supreme quality, strong after-sales support and excellent reputation.

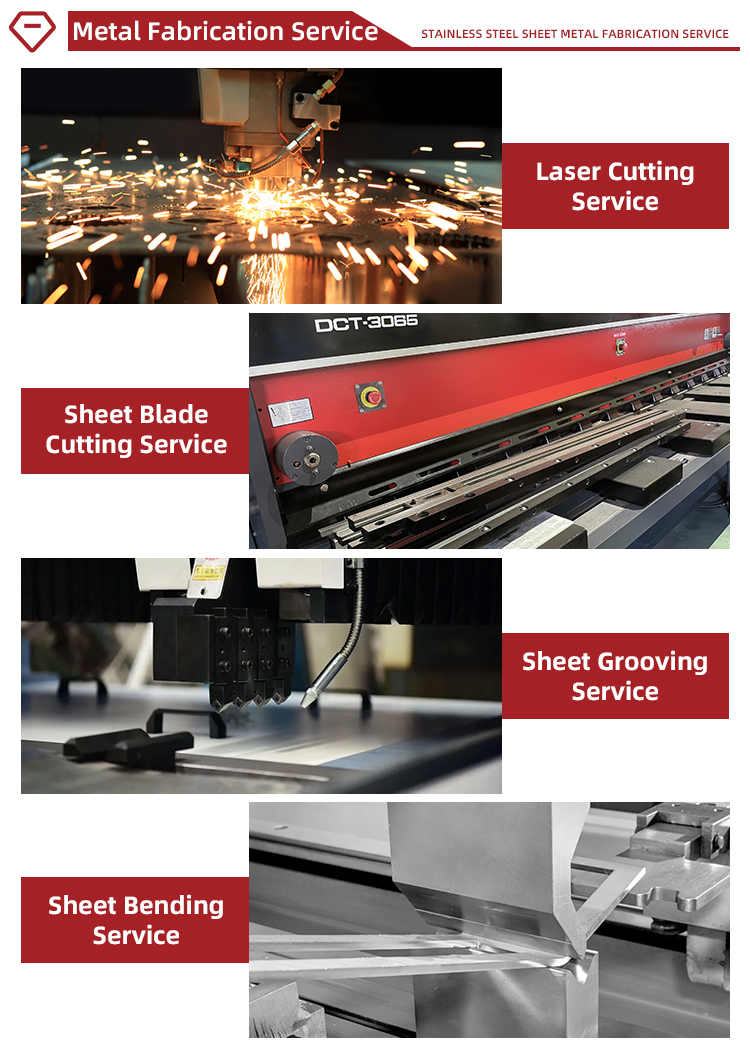

Hermes Steel has a wide range of products and services, covering stainless steel coils, stainless steel sheets, stainless steel pipes, stainless steel bars, stainless steel wires and customized stainless steel products, with steel grades 200 series, 300 series, 400 series; including surface finish like NO.1, 2E, 2B, 2BB, BA, NO.4, 6K, 8K. In addition to meet the individual needs of our customers, we also provide customized 2BQ (stamping material), 2BK (8K processing special material) and other special material, with customized surface’s processing including mirror, grinding, sandblasting, etching, embossing, stamping, lamination, 3D laser, antique, Anti-fingerprint, PVD vacuum coating and water plating. At the same time, we provide with flattening, slitting, film covering, packaging and full sets of import or export trading services.

Foshan Hermes Steel Co., Limited. with years of experience in the field of stainless steel distribution, has been adhering to the aims of customer focus and service orientation, continuously building a professional sales and service team, providing professional solutions to satisfy customers’ various demands through prompt response and ultimately obtaining customer satisfaction to reflect the value of our enterprise. Our mission is to be a stainless steel company providing one-stop service to promptly satisfy the customers’ requirements.

In the process of providing customers with quality products and services for many years, we have gradually established our own corporate culture. Believing, sharing, altruism and persisstence are the pursuits of every staff from Hermes Steel.