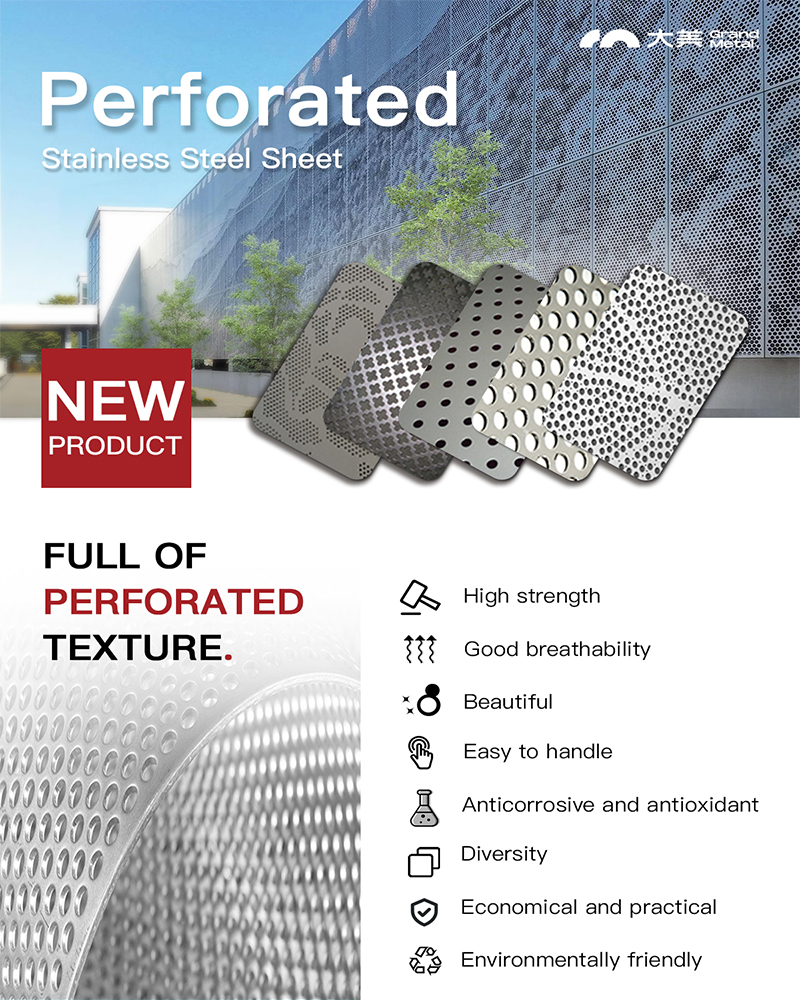

Stainless Steel Perforated Metal Sheets

Perforated stainless steel is a sheet of stainless steel that has been stamped, punched, or cut to create specific hole patterns or openings. It’s utilized for aesthetic purposes like architectural accents and performance like filtration or ventilation.

Benefits of Perforated Stainless Steel

A durable, weather-resistant, and visually striking metal alloy, stainless steel expertly balances form and function.

Stainless steel is a family of iron-based alloys that contain a minimum of roughly 11 percent chromium, which produces a surface oxide layer that protects against degradation. Specific performance characteristics vary by grade, but the material offers an array of benefits.

- Resists corrosion

- High strength

- Long cycle life

- Low weight

- Easy to clean

- Recyclable

- Stands up to extreme temperatures

- Simple to sterilize

- Shiny appearance

- Good weldability

- Strong formability

- Resists magnetism, in some cases

When subjected to impact forces, the surface oxide layer self-heals as long as there is Oxygen, even in small amounts. As a result, stainless steel perforated sheet that sustains nicks, marks, scratches, or other forms of damage won’t corrode.

Stainless Steel Grades – Chemical Composition

| Alloy # | CR | Ni | C | Mn.Max. | Si-Max. | P.Max. | S.Max. | Other Elements |

|---|---|---|---|---|---|---|---|---|

| 304 | 18.0/20.0 | 8.0/11.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 304L | 18.0/20.0 | 8.0/11.0 | 0.03 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 305 | 17.0/19.0 | 10.0/13.0 | 0.12 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 308 | 19.0/21.0 | 10.0/12.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 309 | 22.0/24.0 | 12.0/15.0 | 0.20 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 310 | 24.0/26.0 | 19.0/22.0 | 0.25 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 314 | 23.0/26.0 | 19.0/22.0 | 0.25 Max. | 2.0 | 1.0 | 0.040 | 0.030 | ………. |

| 316 | 16.0/18.0 | 10.0/14.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 2.00/3.00 |

| 316L | 16.0/18.0 | 10.0/14.0 | 0.03 Max. | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 2.00/3.00 |

| 317 | 18.0/20.0 | 11.0/15.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 3.00/4.00 |

| 321 | 17.0/19.0 | 9.0/12.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | Ti 5xC Min. |

| 330 | 14.0/16.0 | 35.0/37.0 | 0.25 Max. | …. | …. | …. | …. | ………. |

| 347 | 17.0/19.0 | 9.0/13.0 | 0.08 Max. | 2.0 | 1.0 | 0.040 | 0.030 | Cb+Ta 10xC Min. |

| 410 | 11.5/13.5 | …. | 0.15 | 1.0 | 1.0 | 0.040 | 0.030 | ………. |

| 430 | 14.0/18.0 | …. | 0.12 Max. | 1.0 | 1.0 | 0.040 | 0.030 | ………. |

| 904L |

Stainless Steel Perforated Metal Supplier

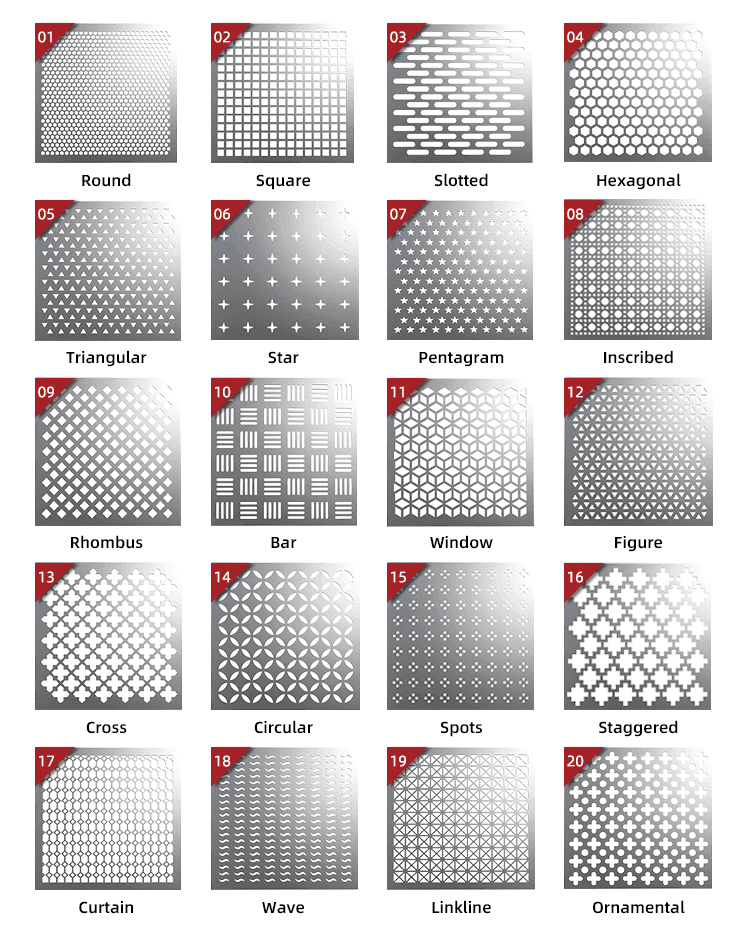

Hermes Steel is a leading provider of metal products for demanding architectural, commercial, and industrial applications. Our area of expertise is fabricating custom perforated metal from high-quality stainless steel sheet metal. Leveraging advanced CNC-guided punches, presses, and rotary-pinned perforation rollers, we can create various shapes and patterns with precise tolerances.

- Round holes

- Square holes

- Slotted holes

- Ornamental or decorative holes

- Custom punching

- Architectural perforated metal

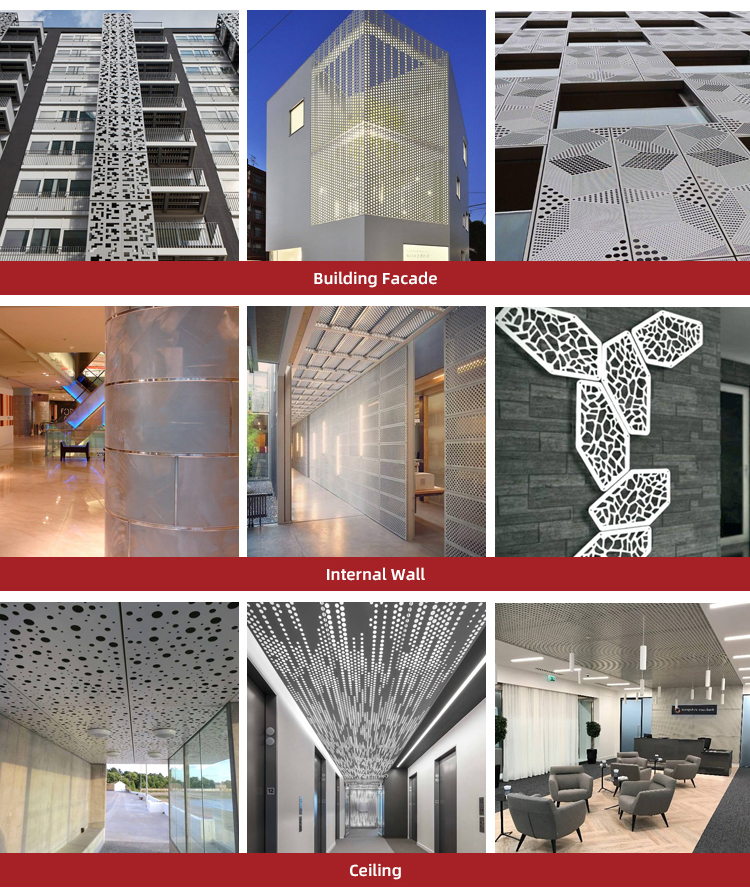

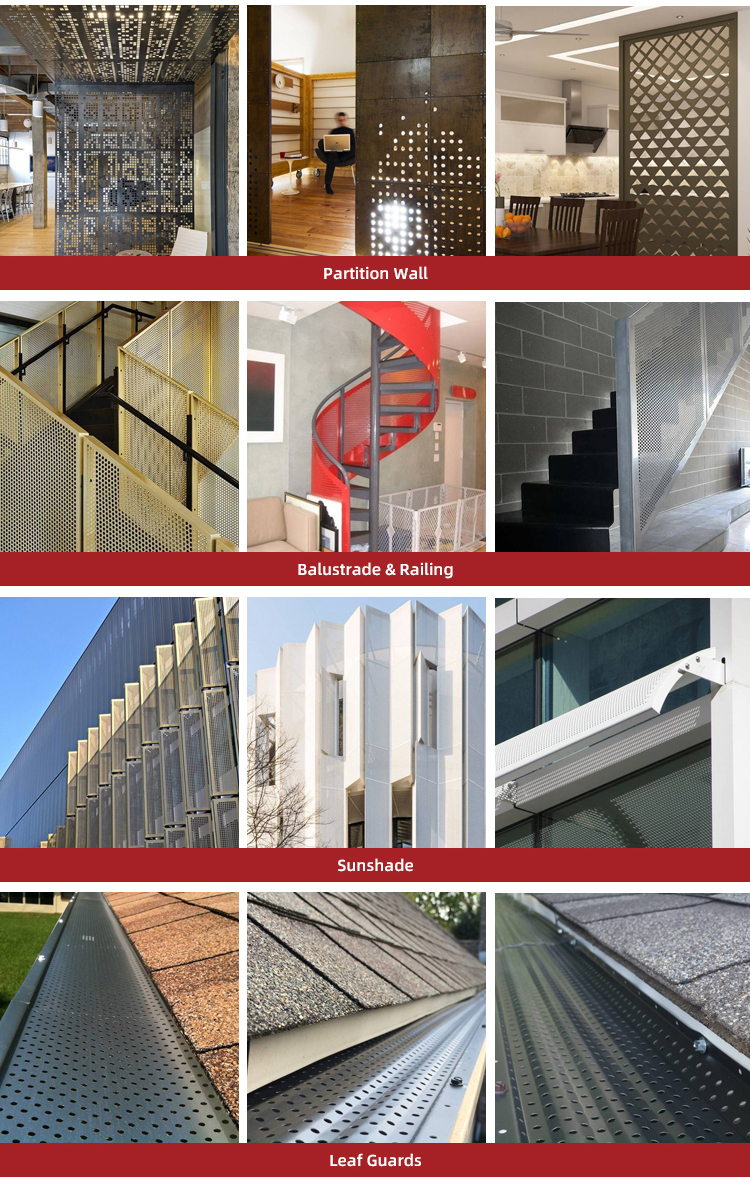

What Are the Applications for Perforated Metal Sheets?

The perforations in stainless steel sheets offer savings in weight and permit the passage of light, liquid, sound, and air. They’re also used to create a decorative or ornamental effect. As a result, perforated stainless steel sheet is suitable for a range of applications.

- Filtration and screening

- Sunshades

- Shelving

- Vessel components

- Ventilation

- Acoustic paneling and speaker grilles

- Light fixtures

- Electronic enclosures

- Building façade infill panels

- Architectural accents

- Retail displays and fixtures

Stainless Steel Grades

We’re happy to create perforated products using stainless steel. Letting us source the material saves you time and hassle, freeing you to focus on your core business. Our technicians can handle an array of stainless steel types.

- Austenitic Stainless Steel – Contains a high percentage of nickel and chromium which enhance its ability to be welded into any shape while providing resistance to corrosion and great strength.

- Ferritic Stainless Steel – These are non-magnetic heat-treatable steels that have good heat and corrosion resistance and are not hardened by heat treatment but are marginally hardenable by cold rolling.

- Duplex Stainless Steel – These are about twice as strong as regular austenitic or ferritic stainless steel. They are extremely corrosion resistant which is attributed to their chemical composition and balanced microstructure.

- Martensitic Stainless Steel – Possess high corrosion resistance and its hardness levels are among the highest of all the stainless steel. These grades are magnetic and can be hardened by heat treatment.

Full-Service Perforated Metal Fabricator

Hermes Steel can custom-fibrate perforated metal products using your print, specification, or purchase order requirements. Our in-house fabrication team can fabricate simple cut sheets, perforated infill panels, custom-punched sheets, and more.

We will work with your drawings to develop a prototype. Upon acceptance, full-scale production kicks off. A variety of industries can benefit from integrating perforated stainless steel products into their applications.

- Architecture

- Petrochemicals

- Agriculture

- Food and beverage processing

- Retail stores and restaurants

- Material webbing, converting, and rolling processes

Post time: Jun-28-2024