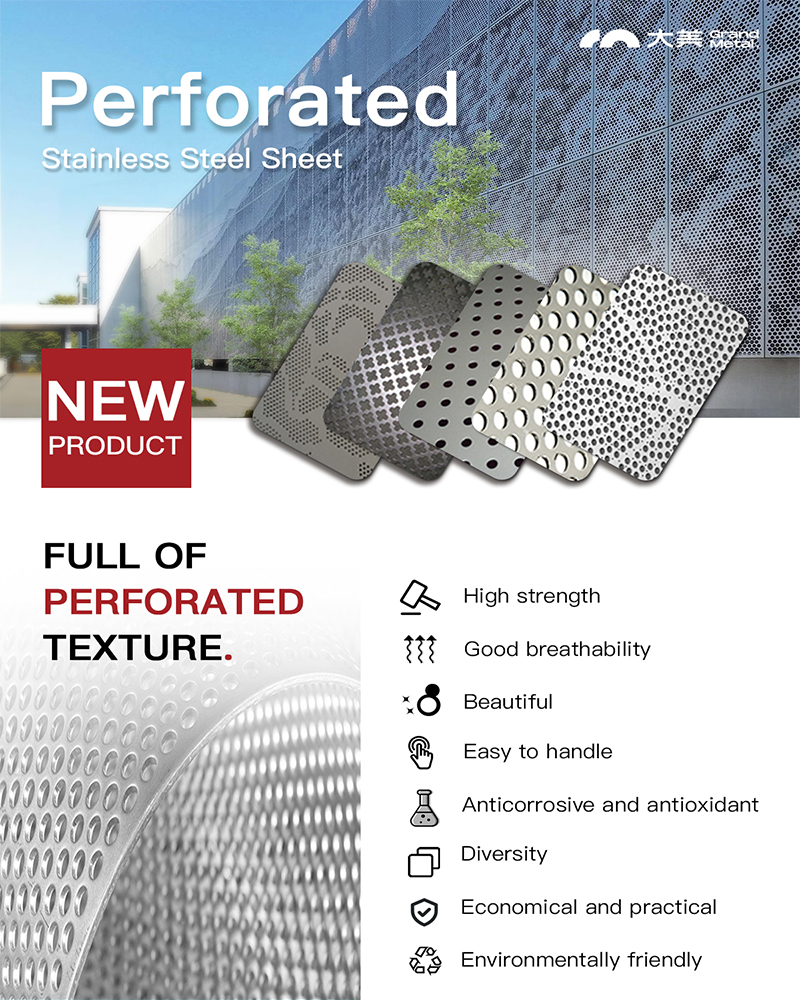

Waraaqo bir ah oo daloolin oo aan daloolin

Birta aan daloolin waa xaashi bir ah oo la shaabadeeyey, la feeray, ama la gooyey si loo sameeyo habab dalool gaar ah ama meel bannaan. Waxa loo istcimaalaa ujeedooyinka bilicda san sida lahjadaha dhismaha iyo waxqabadka sida sifaynta ama hawo-qaadista.

Faa'iidooyinka Birta Daloolin

Daawaha birta ah ee raagaya, cimilada u adkaysata, muuqaal ahaanna soo jiidasho leh, birta aan-dhalatada lahayn waxay si khibrad leh u miisaamaysaa qaabka iyo shaqada.

Birta aan birta lahayn waa qoys ka kooban birta ku salaysan oo ka kooban ugu yaraan 11 boqolkiiba chromium, kaas oo soo saara lakabka oksaydhka oogada kaas oo ka ilaaliya xaalufka. Tilmaamaha waxqabadka gaarka ah waxay ku kala duwan yihiin darajada, laakiin alaabtu waxay bixisaa faa'iidooyin kala duwan.

- Waxay u adkaysataa daxalka

- Xoog sare

- Nolosha meerto dheer

- Miisaan hooseeya

- Fudud in la nadiifiyo

- Dib loo warshadayn karo

- Waxay u taagan tahay heerkul aad u daran

- Fudud in la nadiifiyo

- Muuqaal dhalaalaya

- Weldability wanaagsan

- Habayn adag

- Waxay ka hortagtaa magnetism-ka, xaaladaha qaarkood

Marka ay la kulmaan xoogaga saameynta leh, lakabka oksaydh-ka oogada ayaa is-bogsiinaya ilaa iyo inta uu jiro Ogsajiinta, xitaa xaddi yar. Natiijo ahaan, xaashida daloolin ee birta ah ee xajiya nicks, calamadaha, xagashada, ama noocyada kale ee waxyeellada ma daxaloobayso.

Heerarka Birta Aan-La'aanta ah - Halabuurka Kiimikada

| Alloy # | CR | Ni | C | Mn.Max. | Si-Max. | P.Max. | S.Max. | Qaybaha Kale |

|---|---|---|---|---|---|---|---|---|

| 304 | 18.0/20.0 | 8.0/11.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 304L | 18.0/20.0 | 8.0/11.0 | 0.03 ugu badnaan. | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 305 | 17.0/19.0 | 10.0/13.0 | 0.12 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 308 | 19.0/21.0 | 10.0/12.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 309 | 22.0/24.0 | 12.0/15.0 | 0.20 Max. | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 310 | 24.0/26.0 | 19.0/22.0 | 0.25 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 314 | 23.0/26.0 | 19.0/22.0 | 0.25 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | …………. |

| 316 | 16.0/18.0 | 10.0/14.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 2.00/3.00 |

| 316L | 16.0/18.0 | 10.0/14.0 | 0.03 ugu badnaan. | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 2.00/3.00 |

| 317 | 18.0/20.0 | 11.0/15.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | Mo. 3.00/4.00 |

| 321 | 17.0/19.0 | 9.0/12.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | Ti 5xC Min. |

| 330 | 14.0/16.0 | 35.0/37.0 | 0.25 ugu badnaan | …. | …. | …. | …. | …………. |

| 347 | 17.0/19.0 | 9.0/13.0 | 0.08 ugu badnaan | 2.0 | 1.0 | 0.040 | 0.030 | Cb+Ta 10xC Min. |

| 410 | 11.5/13.5 | …. | 0.15 | 1.0 | 1.0 | 0.040 | 0.030 | …………. |

| 430 | 14.0/18.0 | …. | 0.12 ugu badnaan | 1.0 | 1.0 | 0.040 | 0.030 | …………. |

| 904L |

Iibiyaha birta daloolsan ee birta ah

Hermes Steel waa bixiye hormuud u ah alaabada birta ah ee dalbanaya codsiyada qaab dhismeedka, ganacsiga, iyo warshadaha. Meeshayada khibradda leh waxay soo saartaa birta daloolsan ee caadiga ah ee ka samaysan birta birta ah ee aan tayada lahayn. Ka faa'iidaysiga feerayaasha horumarsan ee CNC-gu hagayo, madbacadaha, iyo rollers-ka daloolinta ee rotary-pined, waxaan abuuri karnaa qaabab iyo qaabab kala duwan oo leh dulqaad hufan.

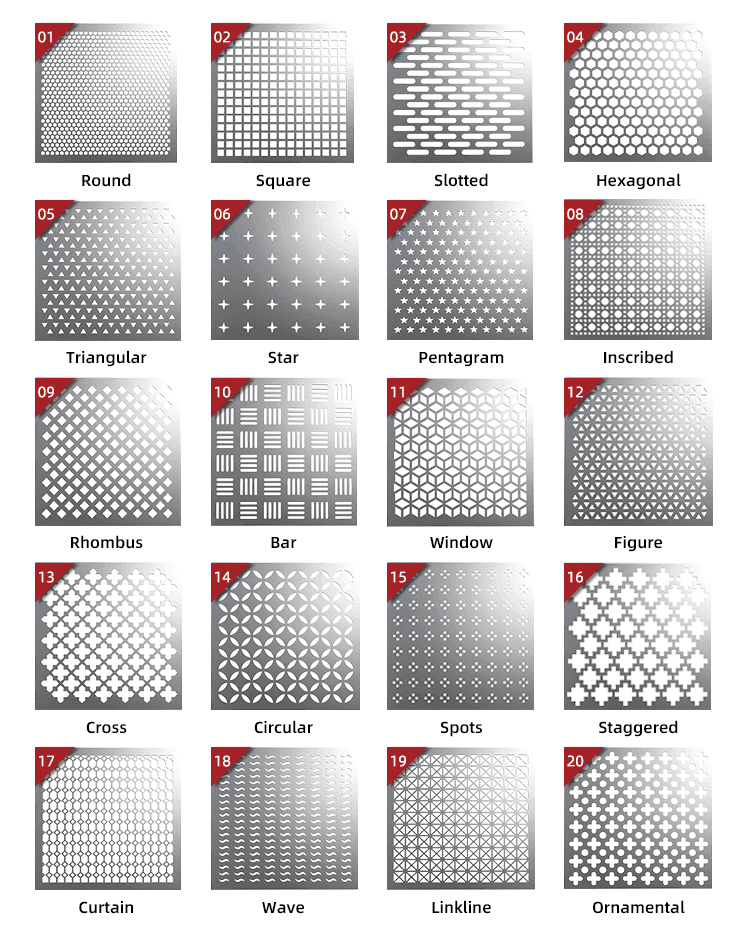

- Godad wareeg ah

- Godad labajibbaaran

- Godad la jeexjeexay

- Godadka qurxinta ama qurxinta

- Feer gaar ah

- Biraha daloolin ee dhismaha

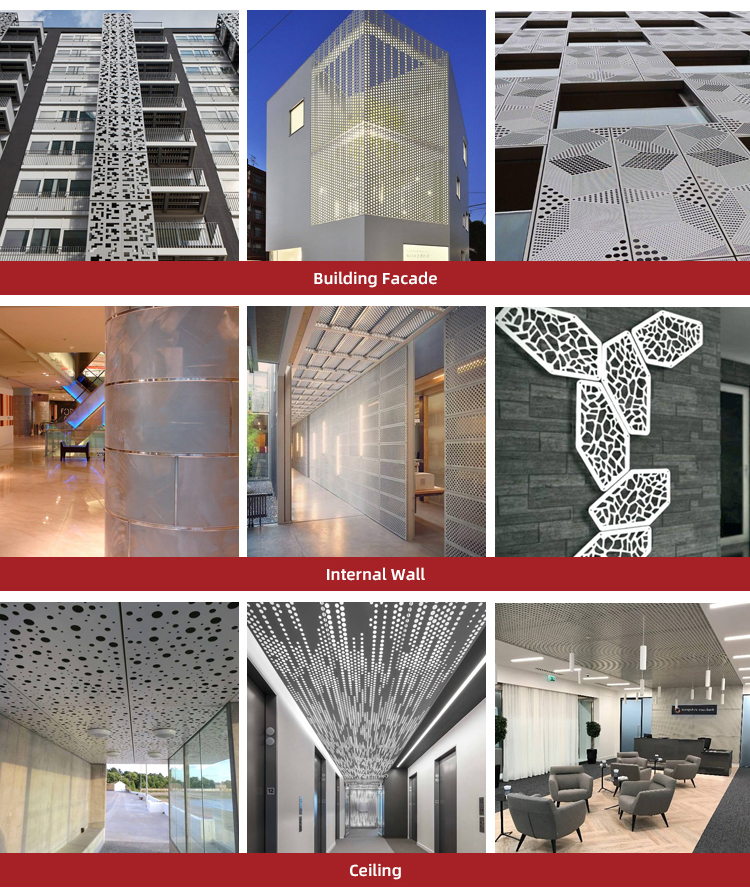

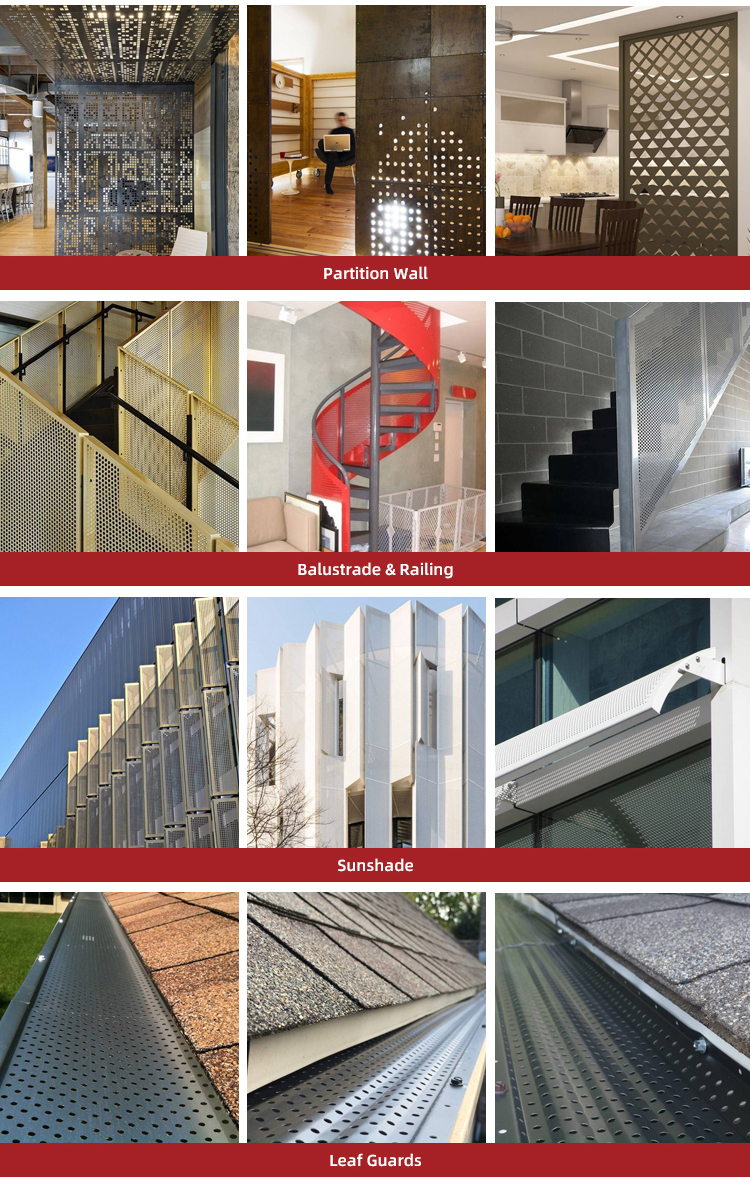

Waa maxay codsiyada xaashida birta ee daloolsan?

Daloolada ku jira xaashida birta ah waxay bixisaa kaydin miisaan waxayna oggolaadaan marinka iftiinka, dareeraha, codka, iyo hawada. Waxa kale oo loo isticmaalaa in lagu sameeyo wax lagu qurxiyo ama qurxinta. Natiijo ahaan, xaashida birta aan daloolin ee daloolku waxay ku habboon tahay codsiyo kala duwan.

- Shaandhaynta iyo baadhista

- Sunshade

- Sheelaynta

- Qaybaha markabka

- Hawo-qaadid

- Acoustic paneling iyo grilles hadalka

- Qalabka laydhka

- Xirmooyinka elegtarooniga ah

- Dhismaha wejiyada buuxinta darbiyada

- Lahjadaha dhismaha

- Bandhigyada tafaariiqda iyo qalabyada

Heerarka Birta Aan Lahayn

Waxaan ku faraxsanahay inaan abuurno alaab daloolsan anagoo adeegsanayna birta aan-xawaalka ahayn. Inaad noo ogolaato inaad ka hesho agabku waxay kaa badbaadinaysaa waqti iyo dhib, taasoo kuu fasaxaysa inaad diirada saarto ganacsigaaga asaasiga ah. Farsamayaqaanadeenu waxay xamili karaan noocyo kala duwan oo bir ah oo aan bir lahayn.

- Austenitic Stainless Steel – Waxa ku jira tiro badan oo nikkel iyo chromium ah kuwaas oo kor u qaadaya awoodda lagu alxanayo qaab kasta iyada oo la siinayo iska caabbinta daxalka iyo xoogga weyn.

- Ferritic Stainless Steel - Kuwaani waa bir aan ahayn bir bir ah oo lagu daweyn karo kulaylka iyo iska caabbinta daxalka oo aan ku engegin daaweynta kulaylka laakiin wax yar ayay ku engegaan qabowga duubista.

- Duplex Stainless Steel - Kuwani waxay qiyaastii laba jeer ka xoog badan yihiin birta caadiga ah ee austenitic ama ferritic ahama. Waxay si aad ah ugu adkaystaan daxalka taas oo loo aanaynayo isku dhafka kiimikada iyo qaab-dhismeedkooda oo dheellitiran.

- Martensitic Stainless Steel- Hayso iska caabbinta daxalka sare iyo heerarkeeda engegnaanteedu waxay ka mid yihiin kuwa ugu sarreeya dhammaan birta-la'aanta. Darajooyinkani waa birlab waxaana lagu adkeyn karaa daawaynta kulaylka.

Warshadaynta Birta Daloolan ee Adeeg Buuxa

Hermes Steel waxay si gaar ah u qurxin kartaa alaabada birta daloolsan iyadoo la isticmaalayo daabacaada, qeexida, ama shuruudaha dalbashadaada. Kooxdayada wax-soo-saarka ee guriga dhexdiisa waxay samayn karaan go'yaal fudud oo la jarjaray, saqafyo dalool leh, go'yaal la feeray, iyo in ka badan.

Waxaanu kula shaqayn doonaa sawiradaada si aanu u samayno prototype. Marka la aqbalo, wax soo saar buuxa ayaa bilaabmaya. Warshado kala duwan ayaa ka faa'iidaysan kara isku dhafka alaabada birta aan daloolin ee daloolsan codsiyadooda.

- Dhismaha

- Kiimikada batroolka

- Beeraha

- Habaynta cuntada iyo cabitaanka

- Dukaamada tafaariiqda iyo makhaayadaha

- Shabakadda shabkada, beddelidda, iyo geeddi-socodka rogid

Waqtiga boostada: Jun-28-2024