Stainless steel water corrugated plate ceiling is a unique way of interior decoration. The stainless steel water corrugated plate is used to make the ceiling, creating a beautiful, modern, and artistic decorative effect. This kind of ceiling is often used in commercial spaces, offices, hotel lobbies, exhibition halls, and other places, and it is gradually becoming popular in home decoration. So do you know how it is installed?

| Table of Contents |

| 1、Installation methods of stainless steel water corrugated plate ceiling |

| •Hanging installation |

| •Paste and install directly |

| •Embedded installation |

| •Hanging wire adjustment and installation |

| •Combined installation |

| 2、Characteristics of stainless steel water corrugated plate ceiling |

| 3、Stainless steel water ripple sheet pattern |

| 4、Hermes steel |

| 5、Conclusion |

Installation methods of stainless steel water corrugated plate ceiling

•Hanging installation

The hanging installation method of the stainless steel water corrugated plate ceiling is usually divided into the following steps:

1. Preparation: First of all, you need to prepare the required materials and tools, such as stainless steel water corrugated panels, ceiling joists, suspension parts, screws, electric drills, screwdrivers, etc.

2. Measuring and Marking: Before installation, measure the size and position of the suspended ceiling according to actual needs, and then use a pencil or other suitable tools to mark on the wall or ceiling to determine the position of the keel and hanging parts .

3. Installing the Suspensions: According to the marked position, use an electric drill to drill holes in the ceiling or wall and insert the suspensions. Make sure the hanger is securely in place to support the weight of the suspended ceiling.

4. Install the keel: Cut the keel according to the pre-measured size, and then connect it with the suspension. Usually, the keel is connected with the suspension by screws to ensure a stable and reliable connection.

5. Installing the stainless steel corrugated panels: Place the stainless steel corrugated panels on the keel one by one, and fix them on the keel with screws. During the installation process, it is necessary to ensure that the position of the board is level and aligned to ensure the beauty and stability of the final effect.

6. Processing details part: After the installation is completed, check the overall flatness and appearance of the suspended ceiling. Details can be adjusted and trimmed if necessary to ensure the suspended ceiling performs as intended.

7. Cleaning and acceptance: After the installation is completed, clean up the construction site and confirm that the suspended ceiling is installed firmly and stably without loosening or potential safety hazards.

•Paste and install directly

The direct paste installation method of the stainless steel water corrugated board ceiling is a simple and effective installation method, which is suitable for some specific situations, such as the scene where the ceiling surface cannot be drilled or the original appearance is required. The following are the specific steps of this installation method:

1. Preparation: First, prepare the required materials and tools, including stainless steel corrugated plates, special metal adhesives, cleaning agents, rubber scrapers, measuring tools, scissors, etc.

2. Clean the surface: Use detergent to clean the ceiling surface, make sure it is clean and dust-free, so that the adhesive can adhere better.

3. Measurement and marking: According to actual needs, use measuring tools to mark on the ceiling to determine the installation position and size of the stainless steel water corrugated plate.

4. Cut the plate: According to the marked size, use scissors to cut the stainless steel water corrugated plate into the required shape and size.

5. Apply adhesive: Apply metal adhesive evenly on the back of the stainless steel water corrugated plate. The choice of adhesive should be made according to the recommendations of the manufacturer or professionals to ensure that the bonding effect is stable.

6. Paste the board: gently paste the stainless steel water corrugated board coated with adhesive to the ceiling according to the marked position. Make sure that the sheeting adheres adequately to the ceiling surface without air pockets or voids.

7. Compaction and fixation: Use tools such as rubber scrapers to gently compact the stainless steel water corrugated panels to ensure that they are tightly adhered to the ceiling. Depending on the adhesive’s instructions, it may take time to set and dry.

8. Deal with the details: After the installation is complete, check the overall effect of the suspended ceiling. If necessary, the details can be adjusted and trimmed to maintain the appearance and quality of the suspended ceiling.

9. Cleaning and acceptance: After the installation is completed, clean up the construction site to ensure that the suspended ceiling is installed stably and reliably without loosening or potential safety hazards.

•Embedded installation

It should be noted that the direct paste installation method needs to choose a suitable adhesive, and pay attention to the amount of adhesive and even application during the operation, so as to ensure that the board can be firmly pasted on the ceiling. Before installation, it is best to read the relevant installation guidelines and instructions, or seek advice from professionals.

The embedded installation method of the stainless steel water corrugated board ceiling is a common decoration method, which can create a unique sense of space and visual effects indoors. The following are the detailed steps of this installation method:

1. Preparation: First of all, make sure to prepare the required materials and tools, including stainless steel water corrugated panels, keels, ceiling materials, screws, electric drills, screwdrivers, measuring tools, etc.

2. Measurement and planning: Use measuring tools to measure the size and shape of the ceiling according to actual needs. According to the measurement results, plan the embedded installation position and shape of the stainless steel water corrugated plate.

3. Prepare the keel: According to the plan, cut the keel according to the corresponding size. The number and arrangement of keels should be adjusted according to the design requirements of embedded installation to ensure that the stainless steel water corrugated plate can be supported and kept stable.

4. Install the keel: Use an electric drill and screws to fix the keel to the ceiling. The position of the keel should match the planned embedded installation position to ensure that the stainless steel water corrugated plate can be embedded in it.

5. Embedding stainless steel water corrugated panels: embed the cut stainless steel water corrugated panels between the keels one by one. Make sure that the boards are embedded in the correct position and that they match the studs.

6. Fixing and adjustment: Use screws to fix the stainless steel water corrugated plate on the keel. Pay attention to the position and number of screws during installation to ensure that the board can be firmly fixed in place.

7. Processing details: After the installation is completed, carefully check the embedding effect of the stainless steel water corrugated plate. If necessary, the details can be fine-tuned and trimmed to ensure the overall effect and quality of the suspended ceiling.

8. Cleaning and acceptance: After the installation is completed, clean up the construction site and check the stability and appearance of the suspended ceiling. Ensure that the embedded installation of the stainless steel water corrugated plate is stable and reliable, without loosening or potential safety hazards.

•Hanging wire adjustment and installation

The hanging wire adjustment installation method of the stainless steel water corrugated board ceiling is a common installation method, which can help adjust the height of the ceiling to make it more uniform and balanced. The following are the detailed steps of this installation method:

1、Preparations: Prepare the required materials and tools, including stainless steel water corrugated boards, hanging wires, hanging wire clips, screws, screwdrivers, measuring tools, etc.

2、Measurement and planning: According to actual needs and design requirements, use measuring tools to determine the height of the ceiling and the position of the suspended ceiling. According to the measurement results, plan the layout and adjustment range of the suspension wire.

3、Install the suspension wire clamp: According to the plan, select a suitable location and fix the suspension wire clamp on the ceiling. The suspension wire clamp is a device used to fix the suspension wire. It needs to be firmly fixed on the ceiling to support the weight of the suspended ceiling.

4、Connect the suspension wire: connect the suspension wire to the suspension wire clamp to ensure that the suspension wire is firm and reliable. The number and arrangement of suspension wires should be reasonably arranged according to the size and design of the ceiling to ensure the balance and stability of the ceiling.

5、Adjust the length of the suspension wire: According to actual needs, use the adjustment device on the suspension wire clip to adjust the length of the suspension wire one by one, so that the height of the ceiling meets the design requirements. When adjusting, pay attention to the tightness of the suspension wire to ensure the stability of the ceiling.

6、Fix the stainless steel water corrugated board: After adjusting the height of the hanging wire, fix the cut stainless steel water corrugated board on the hanging wire one by one. Use screws to firmly fix the board on the suspension wire to ensure the stability and firmness of the suspended ceiling.

7、Dealing with the details: After the installation is complete, check the overall effect of the suspended ceiling. If necessary, the details can be fine-tuned and trimmed to ensure the appearance and quality of the suspended ceiling.

8、Cleaning and acceptance: After the installation is completed, clean up the construction site, and check the stability and appearance of the suspension wire and the stainless steel water corrugated plate. Make sure that the installation of the suspended ceiling achieves the expected effect, and there are no looseness or safety hazards.

•Combined installation

The combined installation method of the stainless steel water corrugated board ceiling is an innovative decoration method, which creates a unique visual effect and a sense of space by combining stainless steel water corrugated boards of different sizes, colors or shapes. The following are the detailed steps of this installation method:

1、Preparations: Prepare the required materials and tools, including stainless steel water corrugated boards, hanging wires, hanging wire clips, screws, screwdrivers, measuring tools, etc. At the same time, stainless steel water corrugated panels of different sizes, colors or shapes can be selected according to design requirements.

2、Measurement and planning: According to actual needs and design requirements, use measuring tools to determine the size of the ceiling and the position of the suspended ceiling. According to the measurement results and the combined design, plan the combination and layout of the stainless steel water corrugated plates.

3、Install the suspension wire clamp: According to the plan, select a suitable location and fix the suspension wire clamp on the ceiling. The suspension wire clamp is a device used to fix the suspension wire to ensure that the suspension wire is firmly fixed on the ceiling.

4、Connect the suspension wire: connect the suspension wire to the suspension wire clamp to ensure that the suspension wire is firm and reliable. According to the combined design, adjust the number and position of the hanging wires to support the combination of stainless steel water corrugated plates.

5、Combination of stainless steel corrugated panels: according to the plan, combine stainless steel corrugated panels of different sizes, colors or shapes one by one. Ensure a tight and balanced combination of panels to create a unique decorative effect.

6、Fixing the stainless steel corrugated panels: After assembling the stainless steel corrugated panels, use screws to fix them on the suspension wire one by one. Make sure the panels are firmly in place for the stability of the suspended ceiling.

7、Dealing with the details: After the installation is completed, carefully check the combined effect of the stainless steel water corrugated panels. If necessary, the details can be fine-tuned and trimmed to ensure the overall effect and quality of the suspended ceiling.

8、Cleaning and acceptance: After the installation is completed, clean up the construction site, and check the stability and appearance of the suspension wire and the stainless steel water corrugated plate. Make sure that the modular installation of the suspended ceiling achieves the desired effect, and there are no looseness or safety hazards.

The combined installation method can bring rich decorative effects and ideas to the stainless steel water corrugated board ceiling, but before installation, it is best to read the relevant installation guide and instructions, or consult a professional for advice to ensure a smooth installation process and achieve the desired effect.

Characteristics of stainless steel water corrugated plate ceiling

Unique appearance: The stainless steel water corrugated plate has a unique corrugated texture and metal texture, which can bring a unique appearance and visual effect to the interior space.

Durability: The stainless steel material has the characteristics of corrosion resistance and wear resistance. The ceiling has a long service life and is not easily affected by the external environment.

Easy to Clean: The surface of the stainless steel material is smooth and easy to clean, just wipe it with a damp cloth to keep it clean.

Flexibility: Stainless steel corrugated panels can be customized in size and shape according to design needs, and can adapt to the decoration requirements of different spaces.

Light reflection: The surface of stainless steel can reflect light, which helps to improve the indoor lighting effect and create a bright space atmosphere.

Modern: Stainless steel is inherently modern and can inject a stylish and modern element into interior spaces.

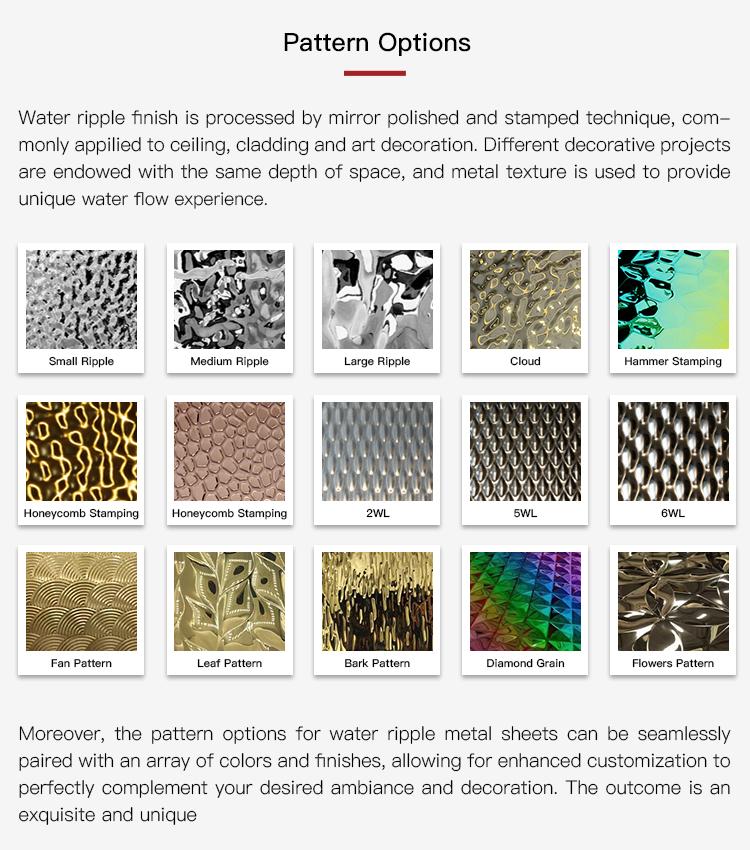

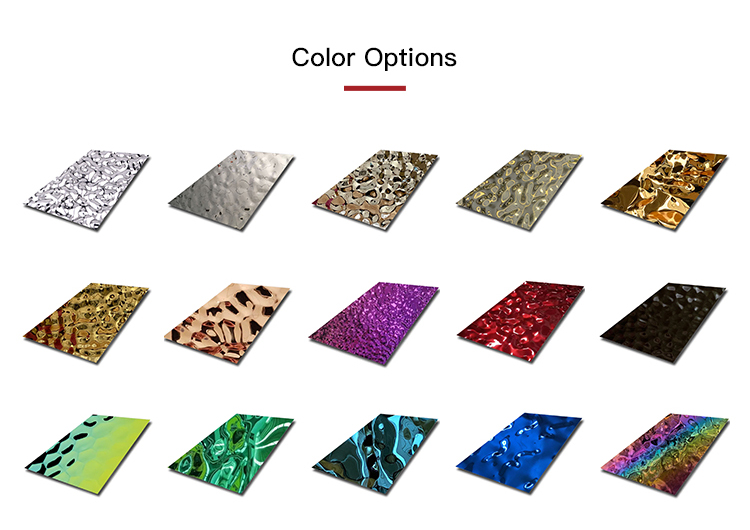

Stainless steel water ripple sheet pattern

Hermes steel

As a premier stainless steel surface designer in China, Foshan Hermes Steel Co., Ltd established in 2006, which strives for stainless steel innovation and quality for more than 10 years. So far, we have developed into a large integrated enterprise of stainless steel material design, and processing.With twelve production equipment production lines, it can meet your various surface design needs

Conclusion

There are many reasons to choose water ripple stainless steel sheets for your next project. These metals are durable, beautiful, and versatile. With so many potential applications, these sheets are sure to add a touch of elegance to any space. Contact HERMES STEEL today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs. Please feel free to CONTACT US!

Post time: Aug-18-2023