Isilingi yeplate yentsimbi yamanzi angenastainless yindlela eyodwa yokuhombisa ngaphakathi. Ipleyiti enamanzi ensimbi engenasici isetyenziselwa ukwenza isilingi, idala isiphumo esihle, sanamhlanje, kunye nobugcisa bokuhombisa. Olu hlobo lwesilingi luhlala lusetyenziswa kwiindawo zorhwebo, ii-ofisi, iindawo zokuhlala iihotele, iiholo zemiboniso, kunye nezinye iindawo, kwaye ngokuthe ngcembe iye idume ngokuhombisa ikhaya. Ngaba uyazi ukuba ifakwe njani?

| Isiqulatho |

| 1,Iindlela zokufakela isilingi yepleyiti yenkcenkce yamanzi ensimbi engenasici |

| •Ufakelo olujingayo |

| •Coca uze ufake ngqo |

| •Ufakelo oluzinzisiweyo |

| •Uhlengahlengiso kunye nofakelo lweengcingo ezijingayo |

| •Ufakelo oludibeneyo |

| 2,Iimpawu zesilingi yepleyiti yentsimbi engatyiwa ngamanzi |

| 3,Ipateni yeshiti yentsimbi engenastainless yamanzi |

| 4,Hermes intsimbi |

| 5,Ukuqukumbela |

Iindlela zokufakela isilingi yepleyiti yenkcenkce yamanzi ensimbi engenasici

•Ufakelo olujingayo

Indlela yokuxhoma yokuxhoma yesilingi yeplate yentsimbi yamanzi engenastainless idla ngokuhlulwa ibe ngamanyathelo alandelayo:

1. Ukulungiselela:Okokuqala, kufuneka ulungiselele izinto ezifunekayo kunye nezixhobo, ezifana neepaneli zensimbi ezingenasici zamanzi, i-ceiling joists, i-suspension parts, i-screws, i-drill yombane, i-screwdrivers, njl.

2. Ukulinganisa nokuMakisha: Ngaphambi kofakelo, linganisa ubungakanani kunye nendawo yesilingi exhonyiweyo ngokweemfuno zokwenene, uze usebenzise ipensile okanye ezinye izixhobo ezifanelekileyo ukuphawula eludongeni okanye kwisilingi ukumisela indawo ye-keel kunye neendawo ezijingayo.

3. Ukufakela ii-Suspensions: Ngokwendawo ephawulweyo, sebenzisa i-drill yombane ukubhoboza imingxuma kwisilingi okanye eludongeni kwaye ufake ukumiswa. Qinisekisa ukuba i-hanger ikhuselekile kwindawo yokuxhasa ubunzima besilingi emisiweyo.

4. Faka i-keel: Sika i-keel ngokobungakanani obulinganiswe ngaphambili, uze uyidibanise kunye nokumiswa. Ngokuqhelekileyo, i-keel idibaniswe nokumiswa ngezikrufu ukuqinisekisa uxhulumaniso oluzinzileyo noluthembekileyo.

5. Ukufakela iipaneli zentsimbi engenasici: Beka i-stainless steel corrugated panels kwi-keel nganye nganye, kwaye uyilungise kwi-keel nge-screws. Ngethuba lokufakwa kwenkqubo, kuyimfuneko ukuqinisekisa ukuba indawo yebhodi ikwinqanaba kwaye ihambelana nokuqinisekisa ubuhle kunye nokuzinza kwesiphumo sokugqibela.

6. Iinkcukacha zokusetyenzwa inxalenye: Emva kokuba ukufakela kugqityiwe, jonga i-flatness iyonke kunye nenkangeleko yesilingi emisiweyo. Iinkcukacha zinokulungelelaniswa kwaye zilungiswe ukuba kuyimfuneko ukuqinisekisa ukuba isilingi emisiweyo yenza njengoko kucetywayo.

7. Ukucoca kunye nokwamkelwa: Emva kokuba ukufakela kugqityiwe, coca indawo yokwakha kwaye uqinisekise ukuba isilingi emisiweyo ifakwe ngokuqinileyo kwaye ngokuzinzileyo ngaphandle kokukhulula okanye iingozi ezinokuthi zikhuseleke.

•Coca uze ufake ngqo

Indlela yokufakela ngokuthe ngqo i-paste ye-stainless steel stainless water corrugated siling yindlela yokufakela elula nesebenzayo, efanelekileyo kwiimeko ezithile ezithile, njengendawo apho umphezulu wesilingi ungenako ukugrunjwa okanye ukubonakala kokuqala kuyadingeka. Oku kulandelayo ngamanyathelo athile ale ndlela yofakelo:

1. Ukulungiselela:Okokuqala, lungiselela izinto ezifunekayo kunye nezixhobo ezifunekayo, kubandakanywa iiplate zensimbi ezingenasici, i-adhesives zetsimbi ezikhethekileyo, ii-agent zokucoca, i-rubber scrapers, izixhobo zokulinganisa, i-scissors, njl.

2. Coca umphezulu: Sebenzisa i-detergent ukucoca indawo yesilingi, qiniseka ukuba icocekile kwaye ayinathuli, ukwenzela ukuba i-adhesive ikwazi ukubambelela kakuhle.

3. Umlinganiselo kunye nokumakishwa: Ngokweemfuno zangempela, sebenzisa izixhobo zokulinganisa ukuphawula kwisilingi ukumisela indawo yofakelo kunye nobukhulu besitya sentsimbi esingenasici samanzi.

4. Sika ipleyiti: Ngokobukhulu obuphawulweyo, sebenzisa isikere ukusika ipleyiti ethathiweyo yamanzi ensimbi engenasici kwimilo kunye nobukhulu obufunekayo.

5. Faka i-adhesive: Faka i-adhesive yentsimbi ngokulinganayo ngasemva kwisitya esinamalahle esinamanzi ensimbi. Ukukhethwa kwe-adhesive kufuneka kwenziwe ngokweengcebiso zomenzi okanye iingcali zokuqinisekisa ukuba umphumo wokubambisana uzinzile.

6. Ncamathelisa ibhodi: Ncamathelisa ngobunono ibhodi yethanki yamanzi ensimbi engenasici efakwe kwi-adhesive kwisilingi ngokwendawo ephawulweyo. Qinisekisa ukuba i-sheeting ibambelela ngokufanelekileyo kwindawo yesilingi ngaphandle kweepokotshi zomoya okanye i-voids.

7. Ukuxinwa kunye nokulungiswa: Sebenzisa izixhobo ezifana ne-rubber scrapers ukuze udibanise ngobumnene iipaneli ze-stainless steel stainless water corrugated panels ukuqinisekisa ukuba zibambelele ngokuqinileyo kwisilingi. Ngokuxhomekeke kwimiyalelo ye-adhesive, kunokuthatha ixesha ukuseta kunye nokomisa.

8. Jongana neenkcukacha: Emva kokuba ukufakela kugqityiwe, khangela isiphumo esipheleleyo sesilingi esimisiweyo. Ukuba kuyimfuneko, iinkcukacha zingalungiswa kwaye zilungiswe ukuze kugcinwe ukubonakala kunye nomgangatho wesilingi esimisiweyo.

9. Ukucoca kunye nokwamkelwa: Emva kokuba ukufakela kugqityiwe, coca indawo yokwakha ukuqinisekisa ukuba isilingi emisiweyo ifakwe ngokuzinzileyo nangokuthembekileyo ngaphandle kokukhulula okanye iingozi ezinokubakho zokhuseleko.

•Ufakelo oluzinzisiweyo

Kufuneka kuqatshelwe ukuba indlela yokufaka i-paste ngokuthe ngqo idinga ukukhetha i-adhesive efanelekileyo, kwaye ubeke ingqalelo kwisixa sokubambelela kunye nokufaka isicelo ngexesha lokusebenza, ukwenzela ukuba kuqinisekiswe ukuba ibhodi inokuthi ifakwe ngokuqinileyo kwisilingi. Ngaphambi kokufakela, kungcono ukufunda izikhokelo zofakelo ezifanelekileyo kunye nemiyalelo, okanye ufune iingcebiso kwiingcali.

Indlela yokufakela edibeneyo yesilingi yebhodi ye-stainless yamanzi yindlela yokuhlobisa eqhelekileyo, enokudala ingqiqo ekhethekileyo yendawo kunye nemiphumo ebonakalayo ngaphakathi. Oku kulandelayo ngamanyathelo aneenkcukacha zale ndlela yofakelo:

1. Ukulungiselela: Okokuqala, qiniseka ukuba ulungiselela izinto ezifunekayo kunye nezixhobo, kubandakanywa iipaneli zensimbi ezingenasici zamanzi, ii-keels, izinto zesilingi, izikrufu, ii-drill zombane, i-screwdrivers, izixhobo zokulinganisa, njl.

2. Umlinganiselo nocwangciso: Sebenzisa izixhobo zokulinganisa ukulinganisa ubungakanani kunye nokumila kwesilingi ngokweemfuno zokwenene. Ngokweziphumo zokulinganisa, cwangcisa indawo yokufakela edibeneyo kunye nokumila kwesitya se-stainless samanzi ensimbi.

3. Lungisa i-keel: Ngokwesicwangciso, sika i-keel ngokobungakanani obuhambelanayo. Inombolo kunye nokulungiswa kwee-keels kufuneka zihlengahlengiswe ngokweemfuno zoyilo lofakelo olufakelweyo ukuze kuqinisekiswe ukuba i-stainless steel water corrugated plate inokuxhaswa kwaye igcinwe izinzile.

4. Faka i-keel: Sebenzisa i-drill yombane kunye nezikrufu ukulungisa i-keel kwisilingi. Isikhundla se-keel kufuneka sihambelane nesicwangciso sofakelo olucwangcisiweyo lokuqinisekisa ukuba i-plate ye-corrugated yamanzi yensimbi engenasici ingafakwa kuyo.

5. Ukufakela iipaneli ezinamazinki ezinamanzi ensimbi engenasici: xhoma iiphaneli ezisikiweyo zentsimbi engenasiphene zamanzi phakathi kweekeels nganye nganye. Qinisekisa ukuba iibhodi zifakwe kwindawo echanekileyo kwaye zihambelana nezikhonkwane.

6. Ukulungiswa kunye nokulungelelanisa: Sebenzisa izikrufu ukulungisa ipleyiti yamanzi yentsimbi engenastainless kwi-keel. Nika ingqalelo isikhundla kunye nenani le-screws ngexesha lofakelo ukuqinisekisa ukuba ibhodi inokulungiswa ngokuqinileyo kwindawo.

7. Ukucubungula iinkcukacha: Emva kokuba ukufakela kugqityiwe, jonga ngononophelo umphumo wokufakela ipleyiti enamalahle ensimbi engenasici. Ukuba kuyimfuneko, iinkcukacha zinokulungiswa kakuhle kwaye zilungiswe ukuze kuqinisekiswe umphumo opheleleyo kunye nomgangatho wesilingi esimisiweyo.

8. Ukucoca kunye nokwamkelwa: Emva kokuba ukufakela kugqityiwe, hlambulula indawo yokwakha kwaye ukhangele ukuzinza kunye nokubonakala kwesilingi esimisiwe. Qinisekisa ukuba ufakelo olufakelweyo lwepleyiti enamalahle ensimbi engenastainless luzinzile kwaye luthembekile, ngaphandle kokukhulula okanye ubungozi obunokubakho.

•Uhlengahlengiso kunye nofakelo lweengcingo ezijingayo

Indlela yokuxhoma intambo yokuxhoma indlela yokufakela isilingi sebhodi ye-stainless steel stainless siyindlela eqhelekileyo yokufakela, enokunceda ukulungelelanisa ukuphakama kwesilingi ukuze ifane kwaye ilinganise. Oku kulandelayo ngamanyathelo aneenkcukacha zale ndlela yofakelo:

1, Amalungiselelo: Lungiselela izinto ezifunekayo kunye nezixhobo, kubandakanywa iibhodi ezinamanzi ensimbi ezingenasici, iingcingo ezijingayo, iikliphu zocingo ezijingayo, izikrufu, i-screwdrivers, izixhobo zokulinganisa, njl.

2. Umlinganiselo kunye nocwangciso: Ngokweemfuno zangempela kunye neemfuno zokuyila, sebenzisa izixhobo zokulinganisa ukumisela ukuphakama kwesilingi kunye nendawo yesilingi emisiwe. Ngokweziphumo zokulinganisa, cwangcisa i-layout kunye noluhlu lohlengahlengiso lwentambo yokumiswa.

3, Faka intambo yocingo yokumiswa: Ngokwesicwangciso, khetha indawo efanelekileyo kwaye ulungise i-clamp yocingo lokumisa kwisilingi. Intambo yocingo yokumiswa sisixhobo esisetyenziselwa ukulungisa intambo yokumiswa. Kufuneka iqiniswe ngokuqinileyo kwisilingi ukuxhasa ubunzima besilingi esimisiweyo.

4, Qhagamshela ucingo lokunqunyanyiswa: qhagamshela ucingo lokumisa kwi-clamp yokumisa ucingo ukuze uqinisekise ukuba ucingo lokumisa luqinile kwaye luthembekile. Inombolo kunye nokulungiswa kweengcingo zokumisa kufuneka zilungiswe ngokufanelekileyo ngokuhambelana nobukhulu kunye noyilo lwesilingi ukuqinisekisa ukulingana kunye nokuzinza kwesilingi.

5, Lungisa ubude bocingo lokunqunyanyiswa: Ngokweemfuno zangempela, sebenzisa isixhobo sokulungelelanisa kwikliphu yocingo yokumisa ukulungelelanisa ubude bocingo lokumisa enye enye, ukwenzela ukuba ukuphakama kwesilingi kuhlangabezane neemfuno zoyilo. Xa ulungelelanisa, qwalasela ukunyanzeliswa kocingo lokumisa ukuqinisekisa ukuzinza kwesilingi.

6 、 Lungisa ibhodi enamazinki entsimbi engenasici: Emva kokulungelelanisa ukuphakama kocingo olujingayo, lungisa ibhodi enqabileyo yamanzi e-stainless steel kwi-wire ejingayo enye enye. Sebenzisa izikrufu ukuze ulungise ngokuqinileyo ibhodi kwintambo yokumiswa ukuze uqinisekise ukuzinza kunye nokuqina kwesilingi emisiwe.

7. Ukujongana neenkcukacha: Emva kokuba ukufakela kugqityiwe, khangela isiphumo esipheleleyo sesilingi esimisiweyo. Ukuba kuyimfuneko, iinkcukacha zinokulungiswa kakuhle kwaye zilungiswe ukuze kuqinisekiswe ukubonakala kunye nomgangatho wesilingi esimisiweyo.

8. Ukucocwa nokwamkelwa: Emva kokuba ukufakela kugqityiwe, coca indawo yokwakha, kwaye ukhangele ukuzinza kunye nokubonakala kocingo lokumisa kunye nesitya se-stainless water corrugated plate. Qinisekisa ukuba ukufakwa kwesilingi emisiweyo kufezekisa umphumo olindelekileyo, kwaye akukho bungozi okanye ukhuseleko.

•Ufakelo oludibeneyo

Indlela yokufakela edibeneyo yesilingi yebhodi yensimbi engenasici iyindlela entsha yokuhlobisa, eyenza umphumo obonakalayo kunye nombono wendawo ngokudibanisa iibhodi ezinamanzi ensimbi ezinobungakanani obuhlukeneyo, imibala okanye iimilo. Oku kulandelayo ngamanyathelo aneenkcukacha zale ndlela yofakelo:

1, Amalungiselelo: Lungiselela izinto ezifunekayo kunye nezixhobo ezifunekayo, kubandakanywa iibhodi ezinamanzi ensimbi ezingenasici, iingcingo ezixhomayo, ii-clips ze-wire clips, izikrufu, i-screwdrivers, izixhobo zokulinganisa, njl. Ngelo xesha, iipaneli zensimbi ezingenasici zamanzi ezinobungakanani obuhlukeneyo, imibala okanye imilo inokukhethwa ngokweemfuno zoyilo.

2. Umlinganiselo kunye nocwangciso: Ngokweemfuno zangempela kunye neemfuno zoyilo, sebenzisa izixhobo zokulinganisa ukulinganisa ubungakanani besilingi kunye nendawo yesilingi emisiwe. Ngokweziphumo zokulinganisa kunye noyilo oludibeneyo, cwangcisa ukudibanisa kunye nokuhlelwa kweeplate ze-corrugated zamanzi ensimbi engenasici.

3, Faka intambo yocingo yokumiswa: Ngokwesicwangciso, khetha indawo efanelekileyo kwaye ulungise i-clamp yocingo lokumisa kwisilingi. I-clamp yocingo olumisiweyo sisixhobo esisetyenziselwa ukulungisa ucingo lokumisa ukuze kuqinisekiswe ukuba ucingo lokumiswa luqiniswe ngokuqinileyo kwisilingi.

4, Qhagamshela ucingo lokunqunyanyiswa: qhagamshela ucingo lokumisa kwi-clamp yokumisa ucingo ukuze uqinisekise ukuba ucingo lokumisa luqinile kwaye luthembekile. Ngokoyilo oludityanisiweyo, lungisa inani kunye nendawo yeengcingo zokuxhoma ukuxhasa ukudibanisa kwamacwecwe ensimbi angenasici.

5, Udibaniso lweepaneli zentsimbi engatyiwayo: ngokwesicwangciso, dibanisa iipaneli zensimbi ezingenasici ezinobungakanani obuhlukeneyo, imibala okanye iimilo nganye nganye. Qinisekisa ukudibanisa okuqinileyo kunye nokulinganisela kweepaneli ukwenza umphumo okhethekileyo wokuhombisa.

6, Ukulungisa iipaneli zentsimbi engatyiwayo: Emva kokudibanisa i-stainless steel corrugated panels, sebenzisa izikhonkwane ukuze uzilungise kwi-wire wireless wire. Qinisekisa ukuba iipaneli ziqinile kwindawo yokuzinza kwesilingi emisiwe.

7. Ukujongana neenkcukacha: Emva kokuba ukufakela kugqitywe, jonga ngokucophelela umphumo odibeneyo wamanzi angenasici. Ukuba kuyimfuneko, iinkcukacha zinokulungiswa kakuhle kwaye zilungiswe ukuze kuqinisekiswe umphumo opheleleyo kunye nomgangatho wesilingi esimisiweyo.

8. Ukucocwa nokwamkelwa: Emva kokuba ukufakela kugqityiwe, coca indawo yokwakha, kwaye ukhangele ukuzinza kunye nokubonakala kocingo lokumisa kunye nesitya se-stainless water corrugated plate. Qinisekisa ukuba ukufakwa kwemodyuli yesilingi emisiweyo kufezekisa umphumo oyifunayo, kwaye akukho nto ikhululekile okanye izingozi zokhuseleko.

Indlela yofakelo edityanisiweyo inokuzisa iziphumo ezityebileyo zokuhombisa kunye neengcinga kwisilingi yebhodi yentsimbi engenasici, kodwa ngaphambi kofakelo, kungcono ukufunda isikhokelo sofakelo esifanelekileyo kunye nemiyalelo, okanye udibane neengcali ukuze ufumane iingcebiso zokuqinisekisa inkqubo yofakelo egudileyo kwaye ufezekise umphumo oyifunayo.

Iimpawu zesilingi yepleyiti yentsimbi engatyiwa ngamanzi

Imbonakalo eyodwa: I-stainless steel stainless water corrugated plate ine-textile ye-corrugated texture kunye nentsimbi yensimbi, enokuzisa imbonakalo ekhethekileyo kunye nefuthe elibonakalayo kwindawo yangaphakathi.

Ukuqina: Izinto zensimbi ezingenasici zineempawu zokumelana ne-corrosion kunye nokuxhatshazwa kokugqoka. Isilingi inobomi benkonzo ende kwaye ayichatshazelwa lula yimeko yangaphandle.

Kulula ukuCoca: Umphezulu wezinto zensimbi ezingenasici zigudileyo kwaye kulula ukuzicoca, zisule nje ngelaphu elimanzi ukuze uhlale ucocekile.

Ukuba bhetyebhetye: Iipaneli zensimbi ezingenasici zingenziwa ngokwezifiso ngobukhulu kunye nokuma ngokweemfuno zoyilo, kwaye ziyakwazi ukulungelelanisa iimfuno zokuhlobisa iindawo ezahlukeneyo.

Ukubonakaliswa kokukhanya: Umphezulu wensimbi engenasici unokubonakalisa ukukhanya, okunceda ukuphucula umphumo wokukhanya kwangaphakathi kunye nokudala indawo ekhanyayo.

Yangoku: Intsimbi estainless yeyangoku kwaye inokufaka into enesitayile kunye neyale mihla kwiindawo zangaphakathi.

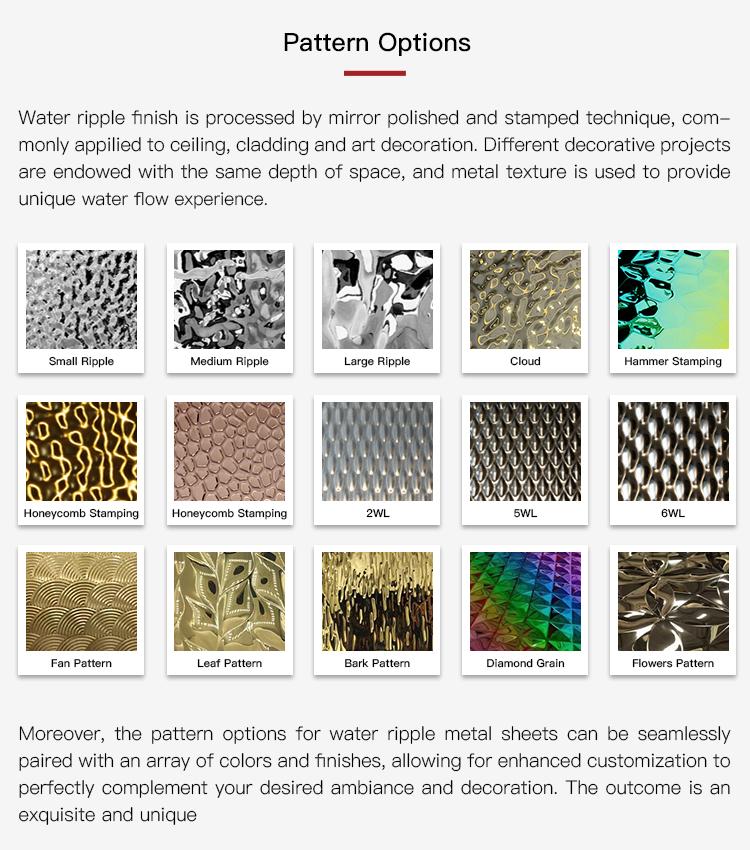

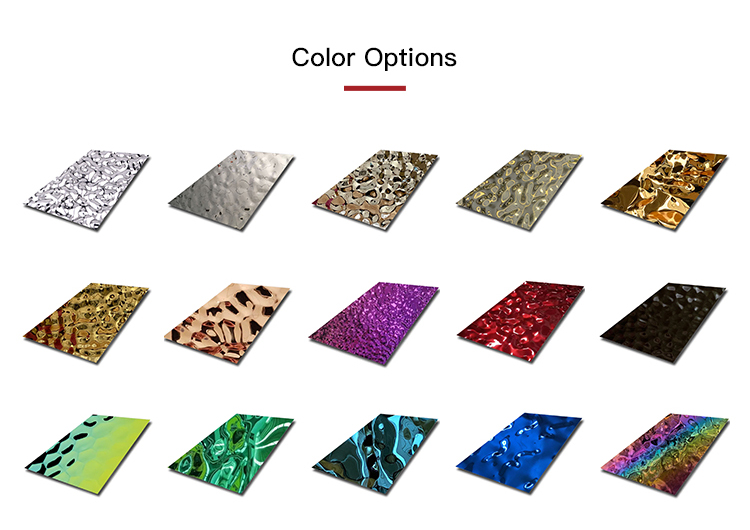

Ipateni yeshiti yentsimbi engenastainless yamanzi

Hermes intsimbi

Njengomyili ophambili wentsimbi ecocekileyo eTshayina, uFoshan Hermes Steel Co., Ltd owasekwa ngo-2006, ozabalazela ukusungula izinto ezintsha zentsimbi kunye nomgangatho ngaphezulu kweminyaka eli-10. Ukuza kuthi ga ngoku, siye sakhula saba lishishini elikhulu elihlanganisiweyo loyilo lwempahla yentsimbi, kunye neprosesa.Ngemigca yokuvelisa izixhobo ezilishumi elinambini, inokuhlangabezana neemfuno zakho zoyilo lomphezulu.

Ukuqukumbela

Kukho izizathu ezininzi zokukhethaamanzi ripple sheets steel stainless kwiprojekthi yakho elandelayo. Ezi ntsimbi zomelele, zintle, kwaye zisebenza ngeendlela ezininzi. Ngezicelo ezininzi ezinokubakho, la maphepha aqinisekile ukuba angongeza umtsalane wobuhle kuyo nayiphi na indawo. Qhagamshelana ne-HERMES STEEL namhlanje ukuze ufunde ngakumbi malunga neemveliso zethu, kunye neenkonzo okanye ufumane iisampuli zasimahla. Siya kukuvuyela ukukunceda ufumane isisombululo esifanelekileyo kwiimfuno zakho. Nceda uzive ukhululekile QHAGAMSHELANA NATHI!

Ixesha lokuposa: Aug-18-2023