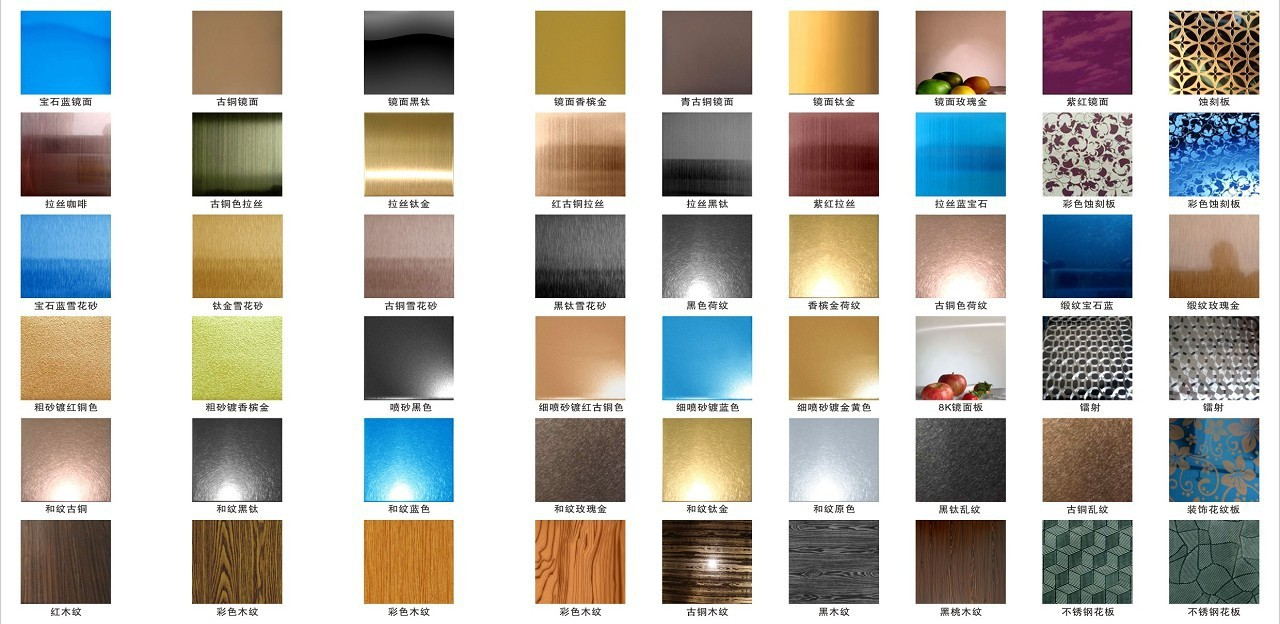

The colors of commonly used stainless steel decorative color plates are available for customers to choose: titanium black (black titanium), sapphire blue, titanium gold, brown, brown, bronze, bronze, champagne gold, rose gold, purple red, emerald green, etc. and can be customized and deployed unique The color matching can meet the various preferences and unique taste pursuits of the owners and architects for the architectural decoration atmosphere.

Exquisite and delicate workmanship, this is not only a product, but also a work of art seduced by fashion charm. Combination brings good life enjoyment.

Will the colored stainless steel decorative panels fade?

I believe that many bigwigs in the decoration industry will encounter this problem, because after the surface treatment of stainless steel, in addition to the etching pattern, there are various colors on the surface, and there is a layer of no fingerprints on the surface layer.At this time, industry leaders will ask, will the color of the surface plating fade? If you are very familiar with the experience of stainless steel finishes, you will be very sure that this color will not generally fade, and you may wonder why it does not generally fade? We all know that stainless steel itself has corrosion resistance, and its performance is better after electroplating! Discoloration generally does not occur. However, in some special cases, the painted surface will fade to varying degrees. Let’s talk about the conditions under which discoloration problems can occur!

1. The color plating time is not enough during the processing

In order to save time and cost, some processing factories will shorten the color plating time of a furnace during surface treatment. In theory, the longer the coloring time, the higher the hardness of the coating. The longer the color of the colored stainless steel decorative plate lasts, the longer it will be used, and it will not fade after 5 to 10 years of use

2. The application of stainless steel is also related

We all know that there is a certain degree of acid-base imbalance in stainless steel. For example, near the coastal area or during the installation process, some acid glue accidentally touches the surface of the colored stainless steel decorative panel, and if it is not handled in time, or the handling method is improper, the surface will be damaged. Color coatings cause varying degrees of damage and even cause stainless steel to rust on steel substrates!

3. External human factors

In our future use, it is inevitable that the surface will be damaged due to improper use. For example, scratches and corrosive liquids can discolor stainless steel trim. If used for a long time, or exposed to the sun and rain for a long time!

Why does the colored stainless steel plate have color difference every time?

Different batches of stainless steel color plates will have different color differences due to changes in temperature, furnace conditions, shift personnel, batches, etc. during the production process. There will be a little color difference, but it is generally invisible to the naked eye.

The reasons for the color difference of stainless steel plates under non-artificial conditions are generally as follows:

One is that the working gas is unevenly distributed in the furnace body, resulting in uneven gas ionization and color difference;

Second, the arc source is unevenly distributed, resulting in insufficient sputtering and chromatic aberration;

The third is beyond the sputtering range, resulting in chromatic aberration;

Fourth, there will be chromatic aberration after no fingerprints.

Post time: Apr-24-2023