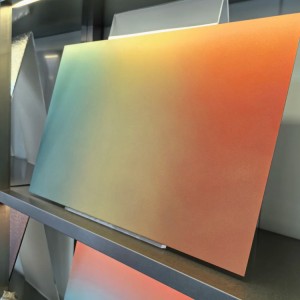

PVDF Coating Dusk Color Stainless Steel Wal Panel Decoration Metal Sheet

|

Type

|

Stainless steel paint plate |

| Thickness | 0.3 mm - 3.0 mm |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max. width 1500mm |

| SS Grade | 304,316, 201,430, etc. |

| Available Base Metal | Steel/Cold Rolled Stainless Steel/Aluminum/Galvanized Steel. |

| Packing way | PVC+waterproof paper + strong sea-worthy wooden package |

| Surface Finish | PVDF Coating |

| Color | Dusk Color |

1. Excellent Weather Resistance

PVDF coating contains 70% fluorocarbon resin with a large number of F-C bonds, which determines its super stability. So it has superior resistance to weathering by ultraviolet light, moisture, or temperature. Its surface will not powder or fade for more than 20 years outdoors.

2. Super Corrosion Resistance

Thanks to its excellent resistance to chemicals, such as acid, alkali, salt, etc., PVDF coating will provide a protective barrier for the base metal. Besides, PVDF coating is 6-10 times thicker than the ordinary coating. The thick coating offers high surface hardness and good wear resistance.

3. Excellent High and Low Temperature Resistance

PVDF coating is applied to metal at a temperature of 200°C above, and on the lower surface using EP epoxy powder thermosetting resin, which can be used at 150 °C. After 10 times of freezing-thawing experiments, the resin layer did not fall off, heave, crack, peel, damage and other phenomena. The coating can be used in the temperature range of -60 ℃ to 150 ℃ for a long time.

4. Maintenance-free and Self-cleaning Performance

PVDF coating has very low surface energy, and the surface dust can be self-cleaned by rain. Besides, its maximum water absorption rate is less than 5% and its minimal friction coefficient is 0.15 to 0.17. So it will not stick to dust scale and oil.

5. Strong Adhesion

PVDF coating has excellent adhesion on the surfaces of metals(steel,stainless steel,aluminum,galvanized steel), plastics cement, and composite materials.

Why Choose Grand Metal?

1. Own Factory

2.Competitive Price

We are the core agent for steel mills such as TSINGSHAN, TISCO, BAO STEEL, POSCO, and JISCO, and our base metal materials include: steel,cold rolled stainless steel,aluminum and galvanized steel etc.

3.Fast Delivery

Standard stock products can be shipped within a few days. Custom orders (depending on the material grade, complexity of the surface treatment, and required slitting widths and tolerances) may take weeks or even months.

4. Quality Control

Our company has a strong after-sales team, and each order is matched with dedicated production staff to follow up.The processing progress of the order is synchronized to the sales staff in real time every day. Each order must go through multiple inspection procedures before shipment to ensure Delivery is possible only if delivery requirements are met.The detailed quality control procedures are as follows:

1. Incoming inspection of base metal (Verify coil/sheet specifications (grade, thickness, width, surface finish - e.g., galvanized, Galvalume, aluminum,stainless steel)., visual checks).

2. In-Process Control (During Coating Line Operation).Surface Pretreatment, Primer Application ,PVDF Topcoat Application,

3. Final Product Inspection & Testing Before Packaging.

4. Certification & Traceability.

What Service Can We Offer You?

To meet the individual needs of our customers, we also provide customized service including material customization,style customization,size customization,color customization,protective film customization etc.

1. Material Customization

Selected steel, cold rolled stainless steel, aluminum and galvanized steel as the base metal sheet.

2.Color Customization

More 15+ years of PVDF Color painting experience,available in more than 10+ colors such as gold,rose gold and blue etc.

3.Style Customization

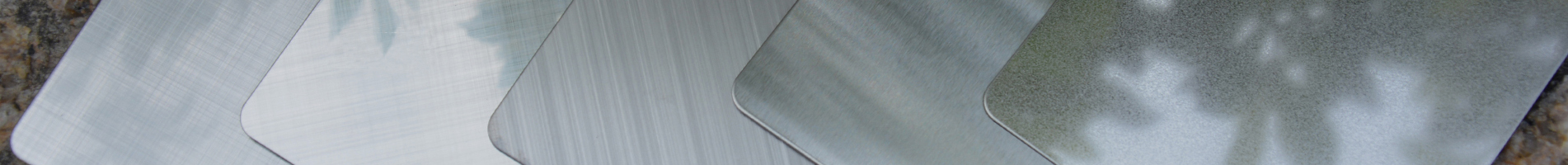

More than 100+ patterns for you to choose,we also provide pattern customized service.Click the photo below to get our product catalog.

4. Size Customization

The standard size of PVDF paint finish stainless steel sheet can be 1219*2438mm,1000*2000mm,1500*3000mm, and the customized width can be up to 2000mm.

5. Protective Film Customization

The standard protective film of PVDF paint finish stainless steel sheet can be used with PE/Laser PE/Optic Fiber Laser PE.

What Else Service Can We Offer You?

We also provide you with the sheet metal fabrication service, including laser cutting service, sheet blade cutting service,sheet grooving service, sheet bending service,sheet welding service, and sheet polishing service etc.

Uses Of PVDF Paint Finish Stainless Steel Sheet

The biggest highlight of this PVDF cherry blossom pink color paint finish decorative stainless steel sheet is that it can reflect colorful colors through sunlight. It not only inherits the corrosion resistance, durability and easy cleaning of stainless steel, but can also be bent for interior decoration, as well as for artwork and building facades. It is the interior decoration material that designers are looking for.

2. What is the typical composition of a PVDF coating system?

3. How thick is the PVDF coating?

4. What substrates are PVDF coatings applied to?

A4: Primarily:

5. How durable is PVDF coating?

A5: Extremely durable, PVDF coatings are known for their ability to withstand decades of harsh weather exposure while retaining color and gloss significantly better than polyester (PE) or silicone-modified polyester (SMp) coatings. Lifespans of 20+ years are common.

6. Does PVDF coating fade?

7. Is PVDF coating easy to clean?

8. Is PVDF coating more expensive than other coatings?

A8: Yes, PVDF coating is typically the most expensive option among common coil coatings (PE, SMP, PVDF) due to the higher cost of the fluoropolymer resin and premium pigments.

Foshan Hermes Steel Co., Limited, establishes a large stainless steel comprehensive service platform integrating international trading, processing, storage and after-sales service.

Our company is located in Foshan Liyuan Metal Trading Center, which is a large stainless steel distribution and trading area in southern China, with convenient transportation and mature industrial supporting facilities. A lot of merchants gathered around the market center. Combining the advantages of market location with strong technologies and scales of major steel mills, Hermes Steel takes full advantages in the field of distribution and quickly shares market information. After more than 10 years of unremitting operation, Hermes Steel establishes professional teams of international trading, large warehousing, processing and after-sales service, providing professional stainless steel import and export trading services to our international customers with fast response, stable supreme quality, strong after-sales support and excellent reputation.

Hermes Steel has a wide range of products and services, covering stainless steel coils, stainless steel sheets, stainless steel pipes, stainless steel bars, stainless steel wires and customized stainless steel products, with steel grades 200 series, 300 series, 400 series; including surface finish like NO.1, 2E, 2B, 2BB, BA, NO.4, 6K, 8K. In addition to meet the individual needs of our customers, we also provide customized 2BQ (stamping material), 2BK (8K processing special material) and other special material, with customized surface’s processing including mirror, grinding, sandblasting, etching, embossing, stamping, lamination, 3D laser, antique, Anti-fingerprint, PVD vacuum coating and water plating. At the same time, we provide with flattening, slitting, film covering, packaging and full sets of import or export trading services.

Foshan Hermes Steel Co., Limited. with years of experience in the field of stainless steel distribution, has been adhering to the aims of customer focus and service orientation, continuously building a professional sales and service team, providing professional solutions to satisfy customers’ various demands through prompt response and ultimately obtaining customer satisfaction to reflect the value of our enterprise. Our mission is to be a stainless steel company providing one-stop service to promptly satisfy the customers’ requirements.

In the process of providing customers with quality products and services for many years, we have gradually established our own corporate culture. Believing, sharing, altruism and persisstence are the pursuits of every staff from Hermes Steel.