what is the stamped stainless steel sheets?

Stamped stainless steel sheets refer to stainless steel plates or sheets that have undergone a metalworking process called stamping. Stamping is a technique used to shape or form metal sheets into various desired shapes, designs, or patterns. In this process, a sheet of stainless steel is placed on a stamping press, and a die (a specialized tool with a specific shape) is pressed onto the metal with high pressure.

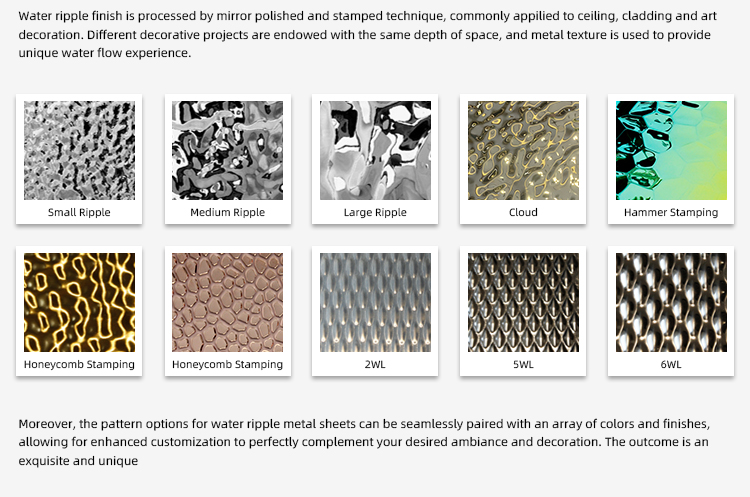

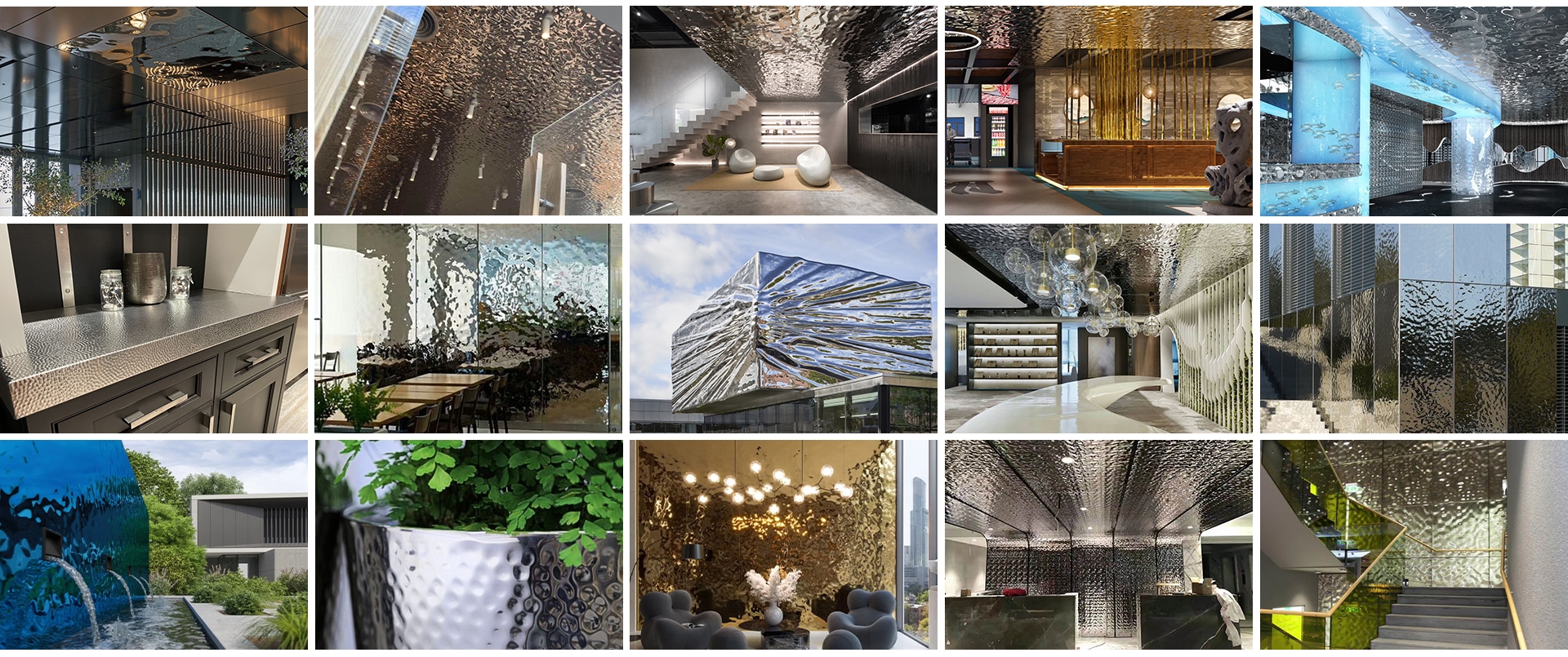

The stamping process deforms the stainless steel sheet, allowing it to take on the shape of the die. This can create a wide range of patterns, textures, or raised designs on the surface of the stainless steel. Stamped stainless steel sheets are often used for decorative purposes in architecture, interior design, and various applications where an aesthetically pleasing, textured, or patterned surface is desired.

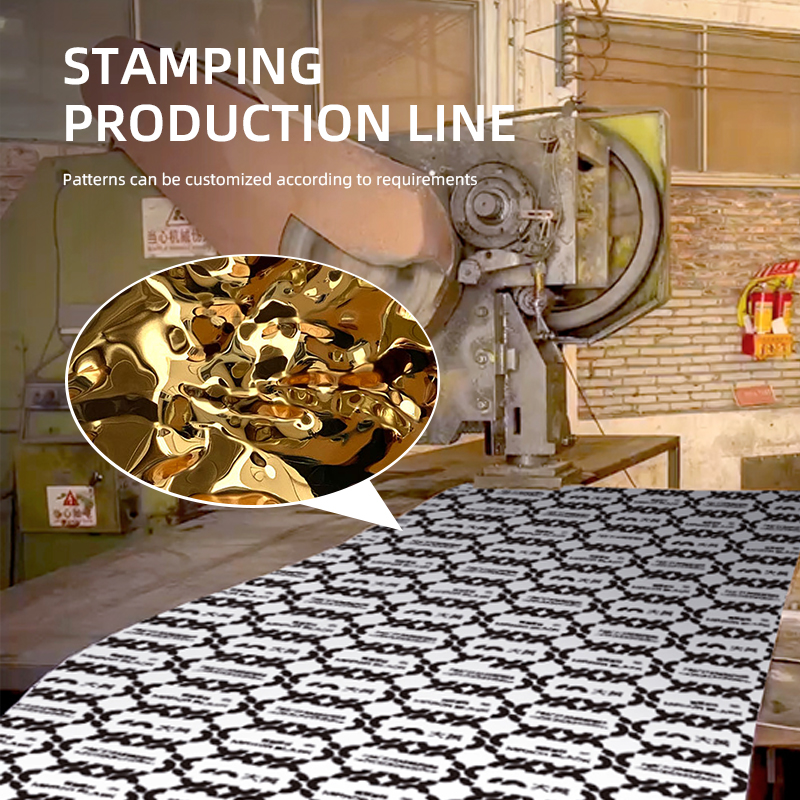

Production process of stamped stainless steel sheets

The production of stamped stainless steel sheets involves several steps in a manufacturing process. Here is a general outline of the typical production method:

-

Material Preparation: The process begins with the preparation of stainless steel sheets. Stainless steel, an alloy primarily composed of iron, carbon, and chromium (among other elements), provides excellent corrosion resistance and durability. The stainless steel sheets are typically supplied in various grades and finishes.

-

Tool and Die Design: The next step involves designing the tools and dies for stamping. Engineers create precise and custom dies that will determine the final shape, pattern, or design to be stamped onto the stainless steel sheets.

-

Stamping Process: The stainless steel sheets are placed onto the stamping press, which is equipped with the designed die. The press applies high pressure to the sheet, pushing it into the die and forming the desired shape or pattern. The stamping process is typically done at room temperature (cold stamping), but in some cases, it may involve heating the material (hot stamping) for specific applications.

-

Post-Stamping Operations: After the stamping process, the stamped stainless steel sheets may undergo additional operations, such as trimming excess material, smoothing edges, or applying protective coatings or finishes to enhance the appearance and durability of the finished product.

-

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the stamped stainless steel sheets meet the required specifications and standards. Inspections are conducted to check for any defects or imperfections.

-

Packaging and Distribution: Once the stamped stainless steel sheets pass the quality control checks, they are packaged appropriately and prepared for distribution to customers or further processing in downstream industries.

It’s essential to note that the production method may vary depending on the specific requirements of the desired stamped stainless steel product, the complexity of the design, and the scale of production. Advanced manufacturing technologies, such as computer numerical control (CNC) systems, may be employed to achieve higher precision and efficiency in the production process.

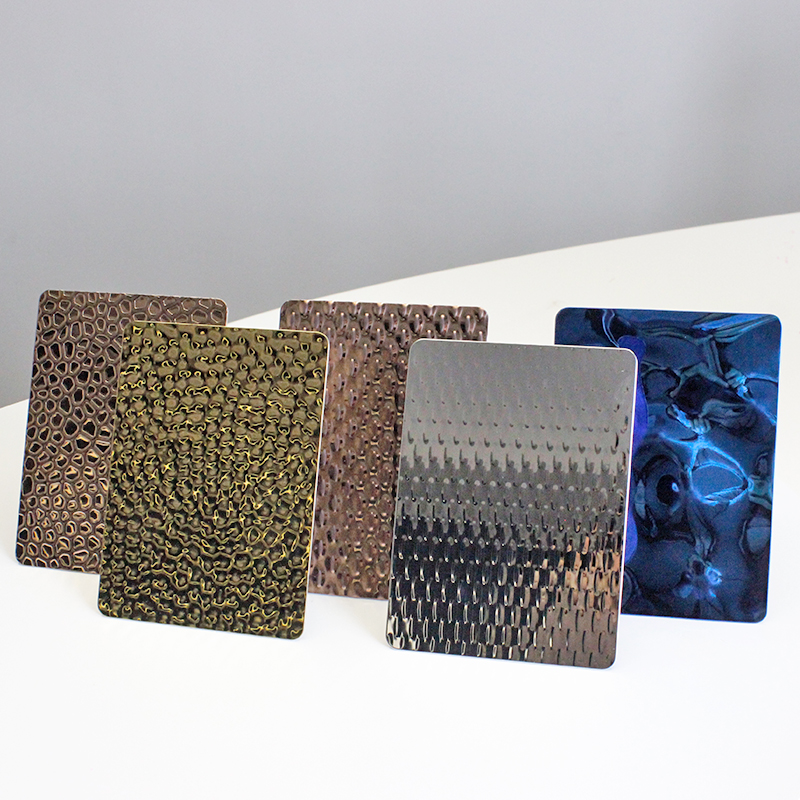

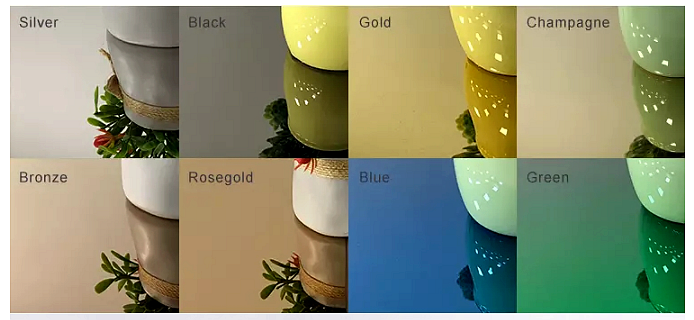

Color Choices

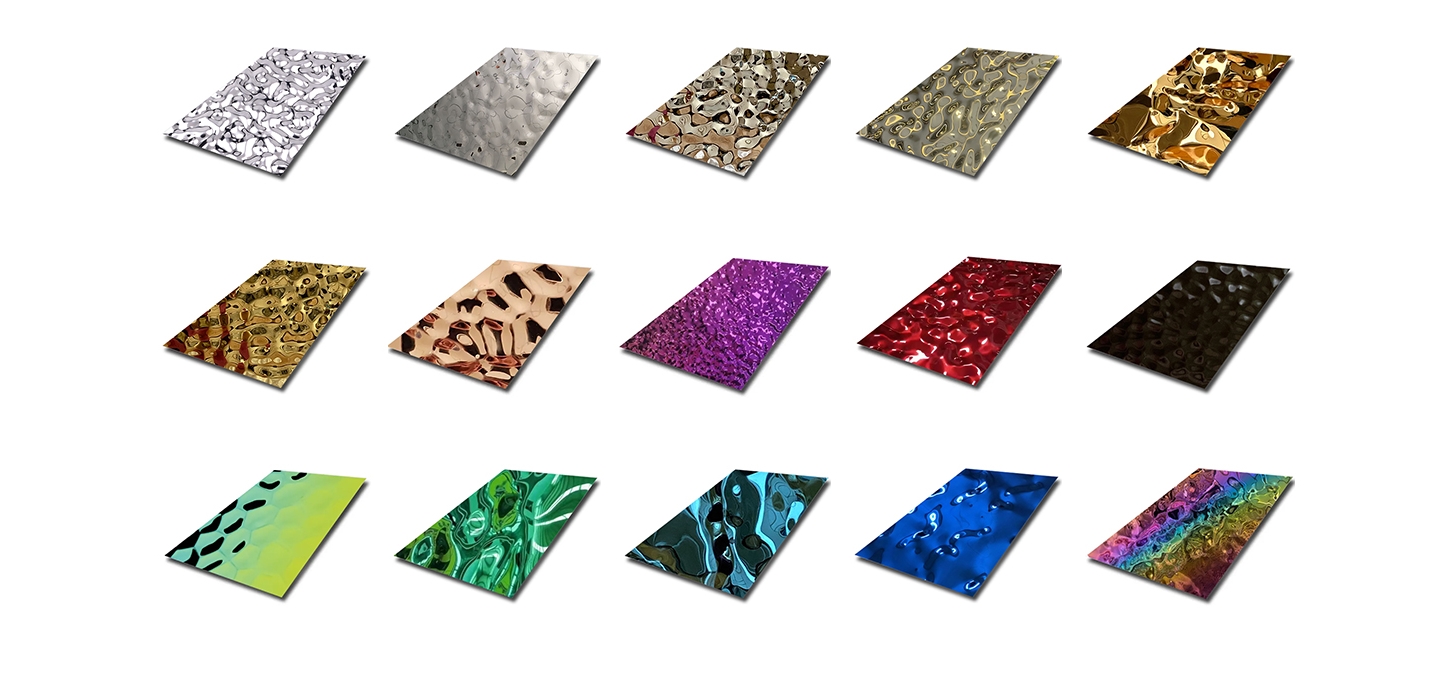

Before stamping, the stainless steel sheets can be mirror polished or brushed as the base surface treatment.

Besides, they may then be PVD coated in a variety of colors, such as gold, rose gold, champagne gold, brasscopper, black, sapphire blue, emerald green, and even rainbow.

Pressure required

The pressure required for stamping stainless steel sheets depends on various factors, including the thickness of the stainless steel, the complexity of the design or pattern, the type of stamping press used, and the properties of the stainless steel grade being stamped. Additionally, the choice between cold stamping (room temperature) and hot stamping (heated material) will also influence the required pressure.

Embossing requires less pressure and can be used on thinner metals, while stamping requires morepressure and can be used on thicker metals.2mm is the maximum thickness allowed for embossed stainless steel sheets, while stamped stainless steemay be up to 3mm thick.

The applications of stamped stainless steel sheet

Stamped stainless steel sheets have a wide range of applications, particularly in industries that value aesthetics, durability, and corrosion resistance. Some common applications include:

-

Architectural and Interior Design: Stamped stainless steel sheets are used in architectural projects and interior design to create visually appealing elements like decorative wall cladding, column covers, elevator panels, and decorative ceilings. The stamped patterns or textures add a touch of elegance and uniqueness to various spaces.

-

Kitchen Appliances: Stainless steel sheets with stamped patterns are utilized for kitchen appliance panels, such as refrigerator doors, dishwasher fronts, and oven panels. The stamped designs can complement the overall kitchen decor and provide a modern and sophisticated look.

-

Automotive Industry: Stamped stainless steel sheets find applications in the automotive sector for interior and exterior trim elements. They can be used for decorative purposes on dashboard panels, door sills, kick plates, and exterior ornamentation.

-

Electronics: In consumer electronics, such as smartphones and laptops, stamped stainless steel sheets can be used for decorative back panels, giving these devices a premium appearance.

-

Retail Fixtures and Displays: Stamped stainless steel sheets are employed in retail environments for displays, signage, and fixtures, where the visually striking patterns enhance the presentation of products.

-

Furniture and Decorative Accents: Stamped stainless steel is used in the furniture industry to create stylish and unique furniture pieces like tabletops, cabinet doors, and decorative accents.

-

Jewelry and Accessories: In the jewelry industry, stamped stainless steel sheets can be used to create intricate patterns and textures for earrings, pendants, bracelets, and other accessories.

-

Marine and Nautical Applications: Stainless steel’s corrosion resistance makes it suitable for marine environments. Stamped stainless steel sheets may be used for marine vessel interior panels, trim, and decorative elements.

-

Art and Sculptures: Artists and sculptors often utilize stamped stainless steel sheets as a canvas for their creations, taking advantage of the versatility and textural possibilities.

-

Aerospace: In the aerospace industry, stamped stainless steel sheets may find applications in aircraft interiors, where aesthetics and lightweight materials are essential.

Stamped stainless steel sheets offer a combination of durability, corrosion resistance, and decorative appeal, making them a versatile choice for various industries seeking high-quality metal finishes with unique designs or patterns.

How to choose the right type of stamped stainless steel sheet for your needs

The type of finish you need

There are several different finishes available, including hairline, mirror, and satin, Each has its own uniquelook and feel, so it’s important to choose the one that best suits your project.

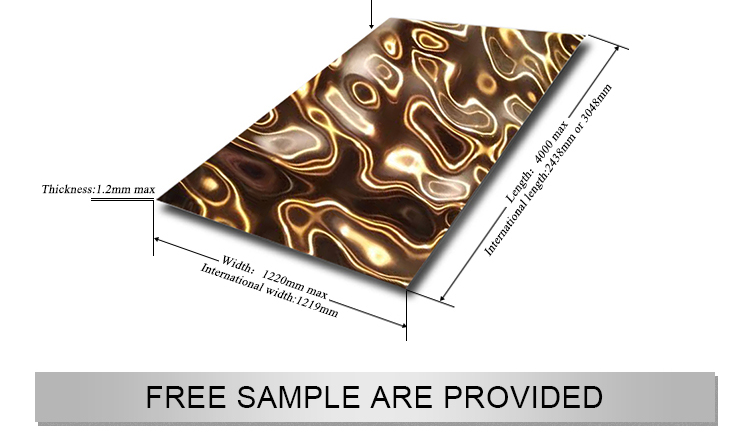

The size of the sheet

stamped sheets come in a varietyof sizes. Be sure to choose one that’s largeenough to complete your project, but not solarge that it’s difficult to work with.Standard size: Width: 1000 / 1219 / 1500mm or Custom-made39′ / 48″ / 59 Length: 2438 / 3048 / 4000mm or Custom-made96″/ 120″/ 157

Material thickness

The thickness of the sheet will affect both the price and the durability. Thicker sheets are more expensive but will last longer.Thin sheets may be less expensive but are more likely to dent easily. The max thickness of stamped stainless steel sheets is 3.0mm respectively.

Conclusion

There are many reasons to choose stamped stainless steel sheets for your next project. These metals are durable, beautiful, and versatile. With so many potential applications, these sheets are sure to add a touch of elegance to any space.Contact HERMES STEEL today to learn more about our products, and services or get free samples. We would be happy to help you find the perfect solution for your needs.Please feel free to CONTACT US !

Post time: Jul-20-2023