athini amashiti entsimbi engenasitampu?

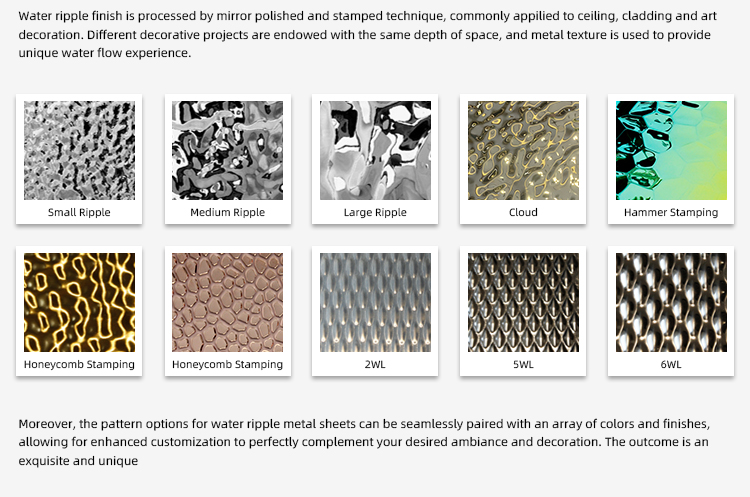

Amashiti entsimbi engenasitampubhekisa kwiipleyiti zentsimbi engenakutyiwa okanye kumaphepha athe afumana inkqubo yokwenza isinyithi ebizwa ngokuba yistamping. Isitampu bubuchule obusetyenziselwa ukubumba okanye ukwenza amaphepha entsimbi abe ziimilo ezahlukeneyo ezinqwenelekayo, uyilo, okanye iipateni. Kule nkqubo, ishidi lensimbi engenasici lifakwe kwi-stamping press, kwaye i-die (isixhobo esikhethekileyo esinemilo ethile) icinezelwe kwintsimbi ngoxinzelelo oluphezulu.

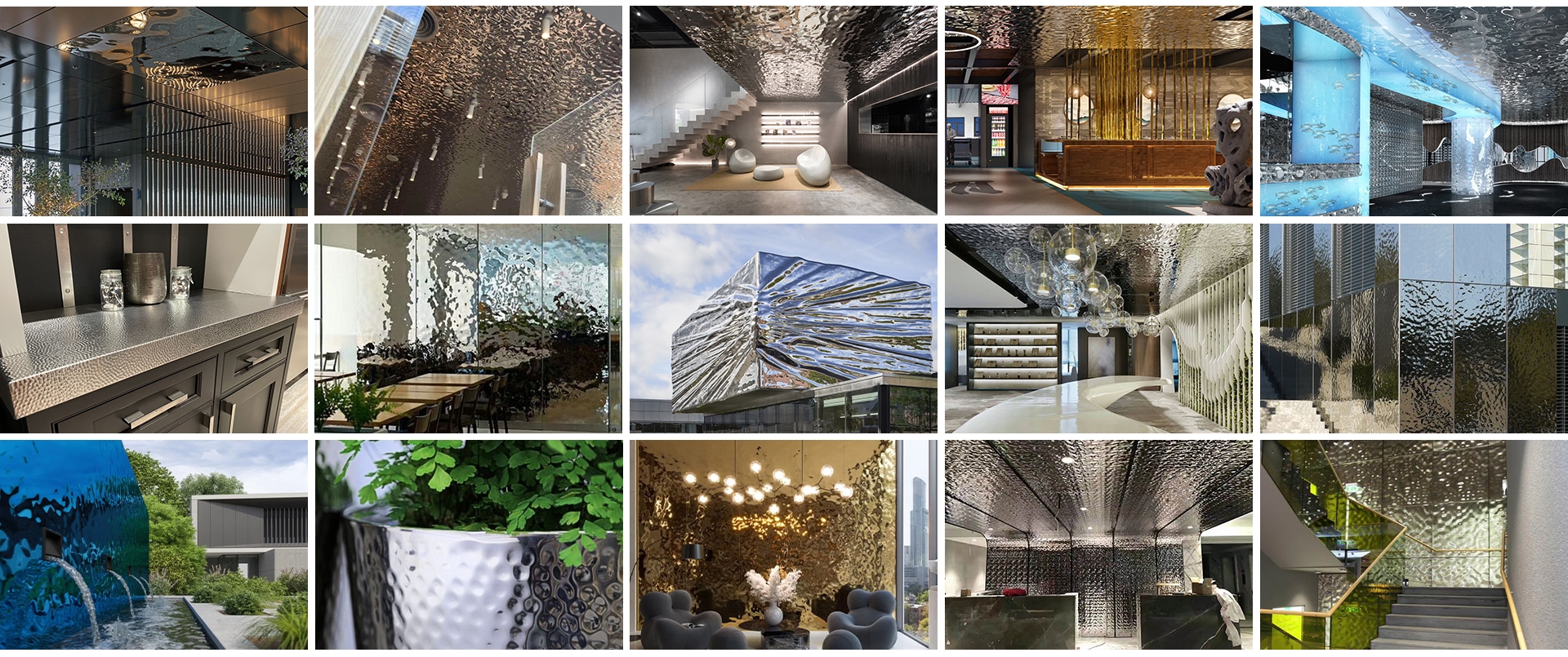

Inkqubo yesitampu iguqula ishidi lensimbi engenasici, livumela ukuba lithathe ubume bokufa. Oku kunokudala uluhlu olubanzi lweepatheni, ukuthungwa, okanye ukuyila okuphakanyisiweyo kumphezulu wensimbi engenasici. Amashiti entsimbi engenasitampu ahlala esetyenziselwa iinjongo zokuhombisa kulwakhiwo, uyilo lwangaphakathi, kunye nosetyenziso olwahlukeneyo apho kufunwa indawo ebukekayo, eyenziweyo, okanye enepateni.

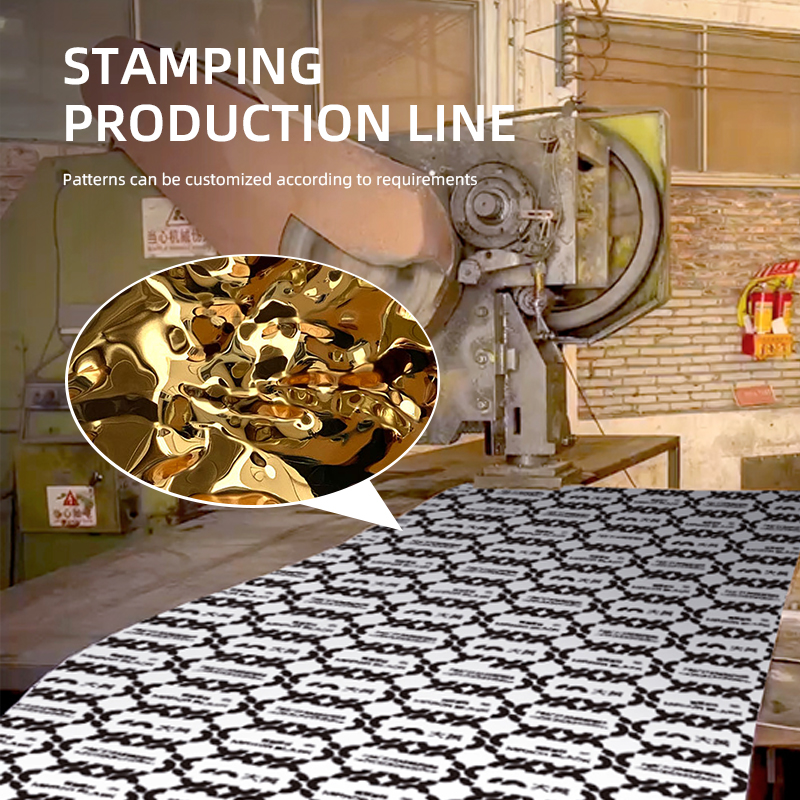

Inkqubo yokuveliswa kwamaphepha ensimbi engenasitampu

Ukuveliswa kwamaphepha ensimbi engenasitampu kubandakanya amanyathelo amaninzi kwinkqubo yokuvelisa. Nalu ulwandlalo oluqhelekileyo lwendlela yemveliso eqhelekileyo:

-

Ukulungiselela Izinto Eziluncedo: Inkqubo iqala ngokulungiswa kwamaphepha ensimbi engenasici. Insimbi engenasici, i-alloy eyenziwe ngentsimbi, i-carbon, kunye ne-chromium (phakathi kwezinye izinto), ibonelela ngokugqwesileyo kokuxhathisa kunye nokuqina. Iishiti zensimbi ezingenasici zibonelelwa ngamabakala ahlukeneyo kunye nokugqiba.

-

Isixhobo kunye noYilo lokufa: Inyathelo elilandelayo libandakanya ukuyila izixhobo kwaye kufa ngenxa yesitampu. Iinjineli zidala ukufa okuchanekileyo kunye nesiko okuya kuthi kumisele imilo yokugqibela, ipateni, okanye uyilo oluza kugximfizwa kushiti wentsimbi.

-

Inkqubo yeStamping: Iishiti zetsimbi ezingenasici zifakwe kwi-stamping press, exhotywe ngokufa okulungiselelwe. Umshicileli usebenzisa uxinzelelo oluphezulu kwiphepha, ukulityhalela kwi-die kunye nokwenza imilo efunekayo okanye iphethini. Inkqubo yesitampu ngokuqhelekileyo yenziwa kwiqondo lobushushu begumbi (i-cold stamping), kodwa kwezinye iimeko, kunokubandakanya ukufudumeza imathiriyeli (i-hot stamping) kwizicelo ezithile.

-

Imisebenzi ye-Post-Stamping: Emva kwenkqubo yesitampu, i-stamp stainless stainless sheets inokuthi iqhube imisebenzi eyongezelelweyo, njengokunciphisa izinto ezingaphezulu, i-smooting edges, okanye ukusebenzisa iingubo zokukhusela okanye ukugqiba ukunyusa ukubonakala kunye nokuqina kwemveliso egqityiweyo.

-

Ulawulo lwemeko: Kuyo yonke inkqubo yokuvelisa, amanyathelo okulawula umgangatho aphunyezwa ukuze kuqinisekiswe ukuba i-stamped stainless steel sheets ihlangabezana neenkcukacha ezifunekayo kunye nemigangatho. Uhlolo lwenziwa ukujonga naziphi na iziphene okanye ukungafezeki.

-

Ukupakishwa kunye nokusasazwa: Emva kokuba i-stamped stainless steel sheets idlulise iisheke zokulawula umgangatho, zipakishwe ngokufanelekileyo kwaye zilungiselelwe ukuhanjiswa kubathengi okanye ukuqhutyelwa phambili kumashishini asezantsi.

Kubalulekile ukuqaphela ukuba indlela yokuvelisa inokwahluka ngokuxhomekeke kwiimfuno ezithile zemveliso efunwayo yesitampu esingenasici, ukuntsokotha koyilo, kunye nobungakanani bemveliso. Itekhnoloji yokuvelisa ekwinqanaba eliphezulu, njengeenkqubo zolawulo lwamanani ekhompyuter (CNC), zinokuqeshwa ukuphumeza ukuchaneka okuphezulu kunye nokusebenza kakuhle kwinkqubo yokuvelisa.

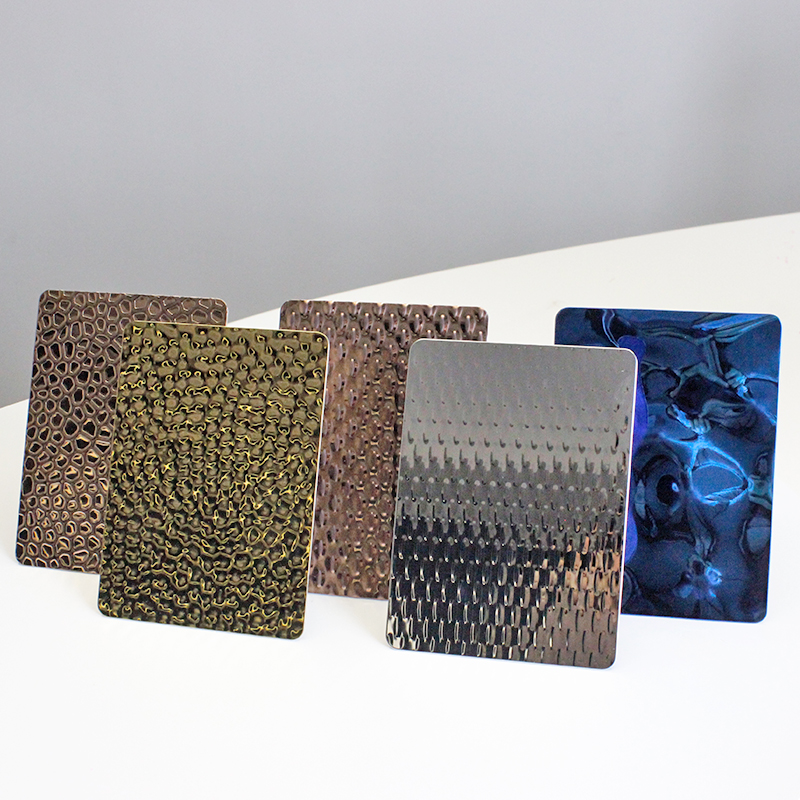

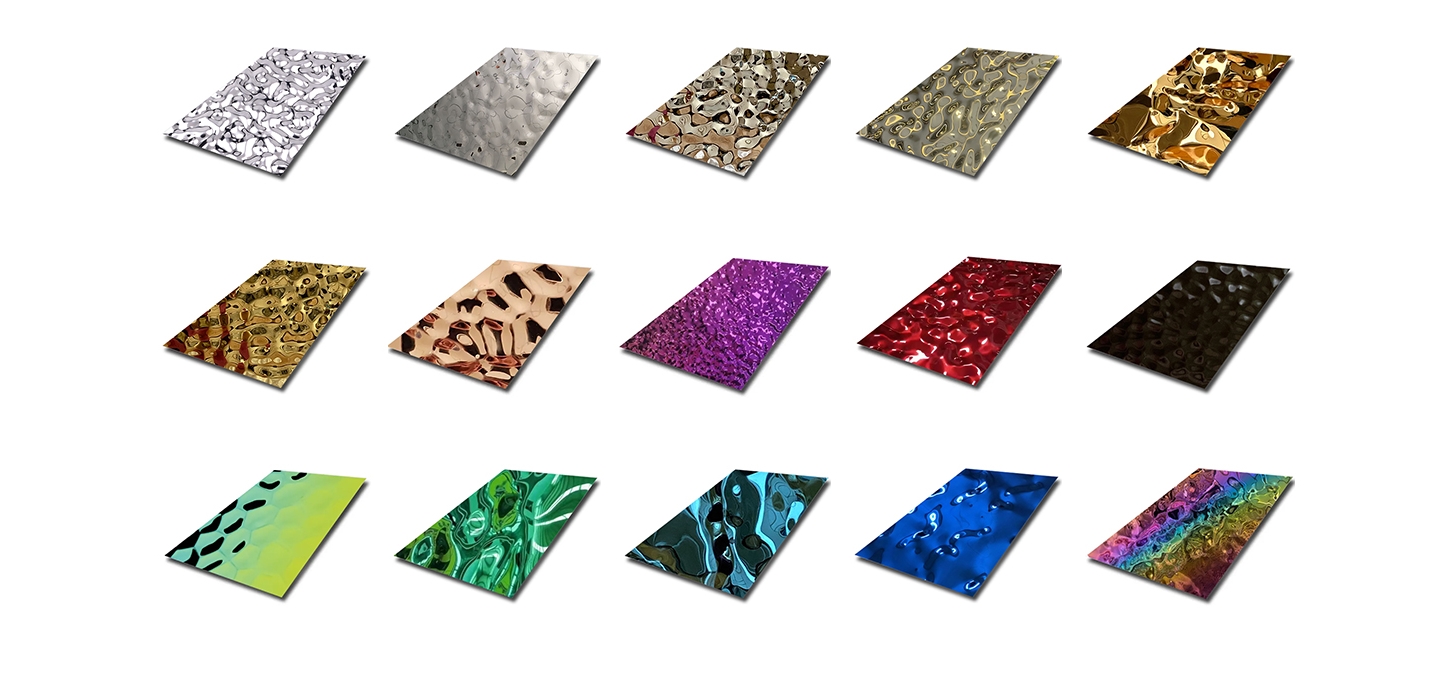

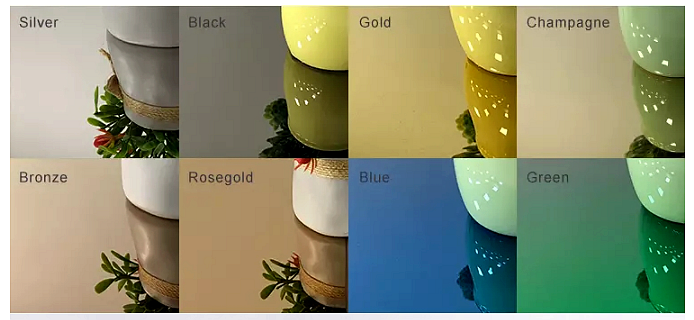

Ukhetho loMbala

Ngaphambi kokunyathela, amashiti ensimbi engenasici anokubaisipili sikhazimlisiwe or ibrashinjengonyango lwesiseko somphezulu.

Ngaphandle koko, baya kuba njaloPVD iqatywengemibala eyahlukahlukeneyo, njengegolide, igolide erozi, igolide yechampagne, ibrasscopper, emnyama, eluhlaza nesafire, eluhlaza neemeraldi nkqu nomnyama.

Uxinzelelo luyafuneka

Uxinzelelo olufunekayo ekunyatheleni amashiti ensimbi engenasici kuxhomekeke kwizinto ezahlukeneyo, kubandakanywa ubukhulu bensimbi engenasici, ukuntsokotha koyilo okanye ipateni, uhlobo lomatshini wokushicilela osetyenzisiweyo, kunye neempawu zebakala lensimbi engenasici. Ukongezelela, ukhetho phakathi kwe-stamping ebandayo (ubushushu begumbi) kunye ne-hot stamping (izinto ezifudumalayo) nazo ziya kuba nefuthe kuxinzelelo olufunekayo.

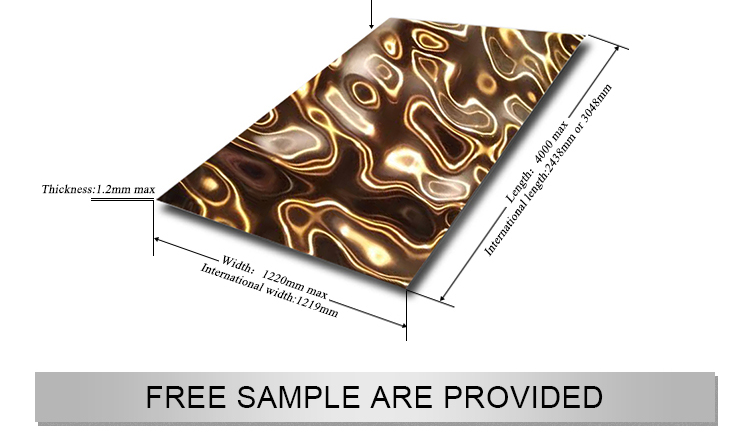

I-Embossing ifuna uxinzelelo oluncinci kwaye ingasetyenziselwa kwisinyithi esincinci, ngelixa isitampu sifuna uxinzelelo olungaphezulu kwaye lunokusetyenziswa kwiintsimbi ezityebileyo.2mm ubukhulu becala obuvunyelweyo kumaphepha ensimbi angenasici, ngelixa isitampu esingenasici sifikelela kwi-3mm ubukhulu.

Ukusetyenziswa kwamaphepha ensimbi engenasitampu

Amashiti entsimbi engenasitampu anoluhlu olubanzi lwezicelo, ngakumbi kumashishini axabisa ubuhle, ukuqina, kunye nokumelana nokubola. Ezinye izicelo eziqhelekileyo ziquka:

-

Uyilo loyilo kunye noyilo lwangaphakathi: Amashiti entsimbi engenasitampu asetyenziswa kwiiprojekthi zoyilo kunye noyilo lwangaphakathi ukwenza izinto ezibukekayo ezinje ngokuhombisa udonga, izigqubuthelo zekholamu, iiphaneli zelifti, kunye neesilingi zokuhombisa. Iipateni ezinesitampu okanye i-texture yongeza umtsalane wobuhle kunye nokungaqhelekanga kwiindawo ezahlukeneyo.

-

Izixhobo zasekhitshini: Amashiti entsimbi engatyiwayo aneepateni ezinesitampu asetyenziswa kwiiphaneli zezixhobo zasekhitshini, njengeengcango zesikhenkcisi, imida yokucoca izitya kunye neepaneli ze-oveni. Uyilo lwesitampu lunokuncedisana nekhitshi elihonjisiweyo kwaye libonelele ngenkangeleko yangoku kunye neyinkimbinkimbi.

-

Ushishino lweemoto: Iishiti zetsimbi ezingenasitampu zifumana izicelo kwicandelo leemoto kwizinto zangaphakathi kunye nezangaphandle ze-trim. Zingasetyenziselwa iinjongo zokuhombisa kwiipaneli zedeshibhodi, iintsimbi zocango, iipleyiti zokukhaba, kunye nokuhlobisa kwangaphandle.

-

Electronics: Kwii-electronics zabathengi, ezifana nee-smartphones kunye neelaptops, iishiti zetsimbi ezingenasitampu zingasetyenziselwa ukuhombisa iipaneli zangasemva, ukunika ezi zixhobo imbonakalo yeprimiyamu.

-

Izinto ezilungisiweyo kunye neziboniso: Amashiti ensimbi anesitampu asetyenziswa kwiindawo zokuthengisa ukuze abonise, imiqondiso, kunye nezixhobo, apho iipateni ezibukekayo ziphucula unikezelo lweemveliso.

-

Ifenitshala kunye neempawu zokuhombisa: Isitampu sentsimbi engenastainless sisetyenziswa kushishino lwefenitshala ukwenza amaqhekeza efanitshala anesitayile kunye nekhethekileyo njengeetafile, iingcango zekhabhathi, kunye neempawu zokuhombisa.

-

Ubucwebe kunye nezixhobo: Kwishishini lezacholo, amashiti ensimbi angenasitampu anokusetyenziswa ukwenza iipateni ezintsonkothileyo kunye nokuthungwa kwamacici, i-pendants, i-bracelets, kunye nezinye izixhobo.

-

Izicelo zaseLwandle kunye neNautical: Ukumelana nokugqwala kwentsimbi yentsimbi kuyenza ilungele iindawo zaselwandle. Amashiti esinyithi angenasitampu anokusetyenziselwa iipaneli zangaphakathi zeenqanawa zaselwandle, i-trim, kunye nezinto zokuhombisa.

-

Ubugcisa kunye neMizobo: Amagcisa kunye nabakroli basoloko besebenzisa amaphepha entsimbi angenasitampu njengeseyile kwindalo yabo, bethatha ithuba lokuguquguquka kunye nokunokwenzeka okubhaliweyo.

-

I-Aerospace: Kwishishini le-aerospace, amashiti ensimbi anesitampu anokufumana izicelo ngaphakathi kwenqwelomoya, apho i-aesthetics kunye nezinto ezilula ziyimfuneko.

Amashiti entsimbi engenasitampuzibonelela ngokudityaniswa kokuqina, ukuxhathisa umhlwa, kunye nesibheno sokuhombisa, nto leyo ebenza ukuba babenokhetho oluguquguqukayo kumashishini ahlukeneyo afuna ukugqitywa kwesinyithi esikumgangatho ophezulu kunye noyilo olulodwa okanye iipateni.

Indlela yokukhetha uhlobo olufanelekileyo lweshiti lensimbi engenasitampu kwiimfuno zakho

Uhlobo lokugqiba oludingayo

Kukho iintlobo ezahlukeneyo zokugqitywa ezikhoyo, kuqukaiinwele, isipili, kwayesatin, Nganye inenkangeleko yayo eyodwa kunye nokuziva, ngoko ke kubalulekile ukukhetha eyona ifanele iprojekthi yakho.

Ubungakanani bephepha

amaphepha anesitampu aza ngokweesayizi ezahlukeneyo. Qinisekisa ukuba ukhethe enye enkulu ngokwaneleyo ukugqiba iprojekthi yakho, kodwa hayi solarge ukuba kunzima ukusebenza.Ubungakanani Standard: Ububanzi: 1000 / 1219 / 1500mm okanye Custom-ezenziwe39′ / 48″ / 59 Ubude: 2438 / 3048/30009/6000mm okanye 6000mm / Custom-made 120″/157

Ubukhulu bezinto eziphathekayo

Ubunzima bephepha buya kuchaphazela zombini ixabiso kunye nokuqina. Amashiti ashinyeneyo abiza kakhulu kodwa aya kuhlala ixesha elide. Amaphepha amancinci asenokungabizi kakhulu kodwa athande ukubobokeka lula. Ubukhulu bobukhulu bamashiti ensimbi engenasitampu yi-3.0mm ngokulandelelanayo.

Ukuqukumbela

Kukho izizathu ezininzi zokukhethaamashiti entsimbi engenasitampukwiprojekthi yakho elandelayo. Ezi ntsimbi zomelele, zintle, kwaye zisebenza ngeendlela ezininzi. Ngezicelo ezininzi ezinokuthi zibe kho, la maphepha aqinisekile ukuba angongeza ukuchukumisa ubuhle nakweyiphi na indawo.fumana iisampulu zasimahla. Siya kukuvuyela ukukunceda ufumane isisombululo esigqibeleleyo kwiimfuno zakho.Nceda uzive ukhululekileQHAGAMSHELANA NATHI !

Ixesha lokuposa: Jul-20-2023