Liyini Ishidi Lensimbi Engagqwali Yesandblasted?

I-Sandblasted Stainless Steel Sheet iyindlela yokwelapha engaphezulu ephatha ubuso bensimbi engagqwali ngokufafaza umfudlana wezinhlayiya ezinesivinini esikhulu (ngokuvamile isihlabathi) ukuze kwakheke isithwathwa. Le ndlela yokwelapha inganikeza ishidi lensimbi engagqwali ukuthungwa nokubukeka okuyingqayizivele, okuyisimanje kanye nobuciko.

Lapho kwakhiwa amapuleti ensimbi engagqwali e-sandblasting, kusetshenziswa isihlabathi noma ezinye izinhlayiya eziqinile, futhi izinhlayiya zishaywa ebusweni bensimbi engagqwali nge-jetting enesivinini esikhulu, ngaleyo ndlela kukhiqizwe i-frosted effec.t.

Izici yalokhu kwelashwa kuyafana naleyo yobuhlalu obuqhunyiswe insimbi engagqwali, okuhlanganisa:

1. Ukubukeka Okuyingqayizivele: Ukuqhuma kwegrit kudala ukubukeka okulinganayo, okuyisithwathwa endaweni yensimbi engagqwali, okunikeza ukuthungwa nokuthungwa kwento.

2. Ukumboza amabala: I-Sandblasting ingavala amabala amancane, imihuzuko nezigxivizo zeminwe endaweni yensimbi engagqwali, okwenza ubuso bubukeke bufana kakhulu.

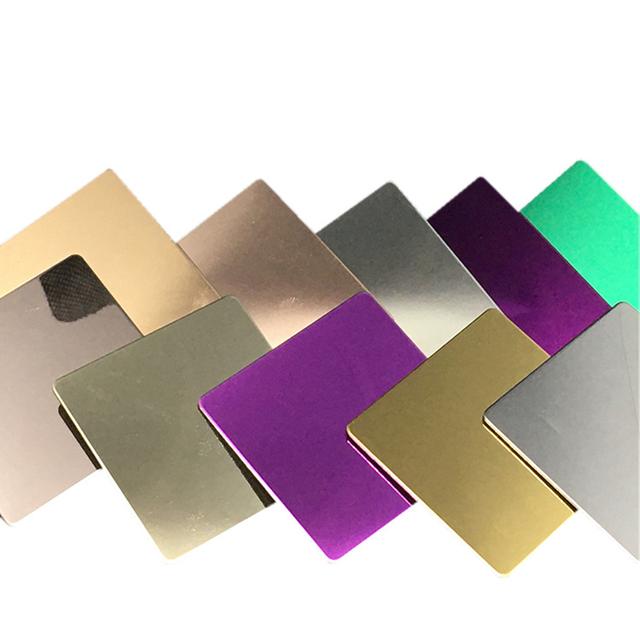

3. Ezobuciko:Ukubukeka kwepuleti lensimbi engenasici ye-sandblasting kungashintshwa ngokuya ngamasu ahlukene we-sandblasting kanye nokukhetha kwezinhlayiya, ngaleyo ndlela kudale imiphumela ehlukahlukene yobuciko.

4. Ukusebenza Okubanzi: Ishidi lensimbi engagqwali elinesandblasted lifanele izicelo zokuhlobisa zangaphakathi nangaphandle, ezinjengokuhlobisa udonga, ifenisha, iminyango namafasitela, njll.

Usayizi Nokuqina Kweshidi Lensimbi Engagqwali Eliqhunyiswe Isihlabathi:

Usayizi : Ubukhulu bamashidi ensimbi engagqwali e-sandblasted bungenziwa ngendlela oyifisayo njengoba kudingekile, futhi ngokuvamile buhluka phakathi kobubanzi obulandelayo:

Ubude: Ubude obujwayelekile busuka ku-1000mm kuya ku-6000mm, kodwa osayizi abade bangenziwa ngokwezifiso njengoba kudingeka.

Ububanzi: Ngokuvamile phakathi kuka-1000mm no-1500mm, kungase futhi kulungiswe ngokuvumelana nezidingo zephrojekthi.

Ubukhulu: Ugqinsi lwepuleti lensimbi engenasici eliqhume nalo lungahluka ngokuya ngezidingo zephrojekthi, ububanzi obujwayelekile bokujiya buhlanganisa:

Ipuleti elincanyana: ngokuvamile phakathi kuka-0.3mm no-3.0mm.

Ipuleti elimaphakathi nelijiyile: ngokuvamile phakathi kuka-3.0mm no-6.0mm.

Ipuleti eliwugqinsi: Ubukhulu bungadlula u-6.0mm, futhi ubukhulu obuthile buncike ezidingweni zephrojekthi.

Inqubo ye-Sandblasted Stainless Steel Sheet:

Inqubo yokukhiqiza i-grit blasted stainless steel sheet ibandakanya izinyathelo eziningi, okulandelayo ukubuka jikelele kwenqubo yokukhiqiza:

Ukulungiselela izinto ezibonakalayo: Khetha ipuleti lensimbi engagqwali elifanelekile njengento eyisisekelo. Izinto zensimbi ezingenasici ezifana no-304 no-316 zivame ukusetshenziswa, futhi ama-alloys ahlukene kanye nokucaciswa kungakhethwa ngokuvumelana nezidingo.

Ukuhlanzeka kwendawo: Qiniseka ukuthi indawo yensimbi engagqwali ihlanzekile futhi ayinawo amafutha, ukungcola namabala. Izindlela zokuhlanza ezivame ukusetshenziswa zihlanganisa ukuhlanza amakhemikhali nokuhlanza ngomshini.

Ukukhetha izinhlayiya: Khetha izinhlayiya ezifanele, ngokuvamile isihlabathi noma ezinye izinhlayiya eziqinile. Ubukhulu nobulukhuni bezinhlayiya kuzothinta isiphetho sokugcina se-matte.

Inqubo yokuqhumisa: Izinhlayiya ezikhethiwe zilayishwa emshinini wokuqhumisa noma idokodo lokuqhuma. Ipuleti lensimbi engagqwali lifakwa egunjini le-sandblasting, futhi izinhlayiya zishayelwa phezulu kwensimbi engagqwali ngokufafaza umfudlana wezinhlayiyana onesivinini esikhulu, ngaleyo ndlela zakhe umphumela oyisithwathwa. Lawula ukushuba, isiqondiso kanye nobude besikhathi sesifutho ukuze ufinyelele ukujula nokubukeka kwe-matte oyifunayo.

Ukulawula Ukujula kweSanding: Lungisa imingcele yesifutho, njengesikhathi sokufutha, usayizi wezinhlayiyana nokucindezela, ukuze ulawule ukujula kwesihlabathi. Izikhathi ezinde zokufutha kanye nezinhlayiya ezinkulu zakha isiphetho se-matte esijulile.

Ukuhlanza nokuhlola: Ngemva kokuqedwa kokuqhuma kwe-sandblasting, ipuleti lensimbi engagqwali lidinga ukudlula ezinyathelweni zokuhlanza nokuhlola ukuze kukhishwe izinhlayiya ezisele nokungcola ukuze kuqinisekiswe ukuthi ikhwalithi yangaphezulu ihlangabezana nezidingo.

Ukwelashwa kwe-anti-corrosion (kuyakhetheka): Ngokwezidingo, ukwelashwa okunqanda ukugqwala kungenziwa epuleti lensimbi engenasici elisesihlabathini ukuze kuthuthukiswe ukumelana nokugqwala.

Ukupakisha nokuthunyelwa: Ngemuva kokuthi konke ukucutshungulwa sekwenziwe, amapaneli ensimbi engenasici ane-sandblasted agcwele futhi alungele ukuthunyelwa kusuka embonini.

Izindawo zokusebenza ze-Sandblasted Stainless Steel Sheet:

Amashidi ensimbi engagqwali anesandblasted ayizinto eziguquguqukayo ezithola ukusetshenziswa ezimbonini ezahlukahlukene ngenxa yobuhle bawo obuhlukile nokusebenza kwawo. Nazi ezinye izindawo ezijwayelekile zokufaka izicelo zamashidi ensimbi engenasici anesandblasted:

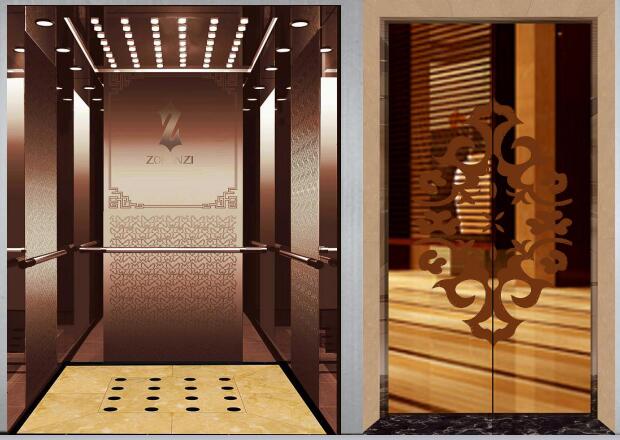

1. Ingaphakathi Design: Amashidi ensimbi engenasici anesandblasted asetshenziswa kakhulu ekwakhiweni kwangaphakathi ukuze kwakhiwe izikhala zesimanje nezesitayela. Angasetshenziselwa ukuvala udonga, amaphaneli okuhlobisa, abahlukanisi bamagumbi, nezinye izakhi zokuklama ukwengeza ukuthungwa nokuthakasela okubonakalayo.

2. Izici Zokwakha:Lawa mashidi avame ukusetshenziswa kumaphrojekthi wezakhiwo ukuthuthukisa ukubukeka kwezakhiwo. Angafakwa kuma-facade, amakholomu, nezinye izakhi zokwakha ukuze kwakheke ukubukeka okuhlukile nokwesimanje.

3. Ifenisha: Amashidi ensimbi engenasici anesandblasted angasetshenziswa ekwakhiweni kwefenisha ukwengeza ukuthinta okuyinkimbinkimbi. Zingasetshenziselwa iziqongo zetafula, ama-countertops, izicabha zekhabhinethi, nezinye izingcezu zefenisha, zinikeze ukuthungwa okuyingqayizivele nokuqedwa kwendawo.

4. Ikhishi kanye neBathroom:Ezindaweni zokuhlala nezohwebo, kusetshenziswa amashidi ensimbi engagqwali anesandblasted ekhishini nasendlini yokugezela. Angasetshenziselwa ama-backsplashes, ama-countertops, nama-sink azungezile ukuze kuzuzwe ukubukeka kwesimanje nokunhle.

5. Izindawo Zokudayisa Nezohwebo: Lawa mashidi asetshenziswa ezindaweni zokuthengisa nezohwebo ukuze enze imibukiso edonsa amehlo, imbobo yodonga, nezimpawu. Ukubukeka kwabo okuthungwe kungasiza ukudonsa ukunaka futhi kube nomthelela ku-ambience jikelele yesikhala.

6. Imboni Yezihambi:Amashidi ensimbi engagqwali anesanti asetshenziswa emahhotela, ezindaweni zokudlela, nasezindaweni zokuphuzela ukuze kuthuthukiswe idizayini yangaphakathi. Angasetshenziselwa amaphaneli odonga okuhlobisa, ama-bar fronts, nezinye izakhi zokuklama ezifaka isandla kumkhathi jikelele.

7. Amakheshi kanye nezitebhisi ezizihambelayo:Ama-elevator nezitezi ezizihambelayo ngokuvamile zihlanganisa amashidi ensimbi engenasici anesandblasted ezindaweni zawo zangaphakathi. Ukuqedwa okuthungwe kungangeza ukuthinta kokunethezeka kulezi zici zokusebenza.

8. Izitendi Zombukiso:Emibukisweni yezohwebo nasemibukisweni, amashidi ensimbi engagqwali ane-sandblasted angasetshenziswa ukuze kwakheke imibukiso edonsa ukunaka namadokodo, kwengeze isici esiyingqayizivele esibonakalayo embukisweni.

9. Izesekeli Zezimoto:Amashidi ensimbi engenasici angasetshenziswa embonini yezimoto ukunquma ingaphakathi nengaphandle, njengamaphaneli edeshibhodi, izibambo zezicabha, nama-accents okuhlobisa.

10.Ubuciko Nezithombe:Abaculi nabaqophi bangasebenzisa amashidi ensimbi engenasici enziwe isihlabathi ukuze bakhe izindawo ezithungwe emisebenzini yabo yobuciko, ezibaziweyo, nasekufakweni kwabo.

Kubalulekile ukuqaphela ukuthi izindawo zokufaka izicelo azikhawulelwe ezibonelweni ezishiwo ngenhla. Amashidi ensimbi engenasici anesandblasted anikeza amathuba anhlobonhlobo ngenxa yokukhanga kwawo kobuhle, ukuqina, kanye nekhono lokwengeza ukujula ezindaweni ezihlukahlukene. Ukukhethwa kwendawo yesicelo kuncike ezidingweni ezithile zephrojekthi kanye nomthelela obonakalayo oyifunayo.

Isikhathi sokuthumela: Aug-21-2023