What Is Sandblasted Stainless Steel Sheet?

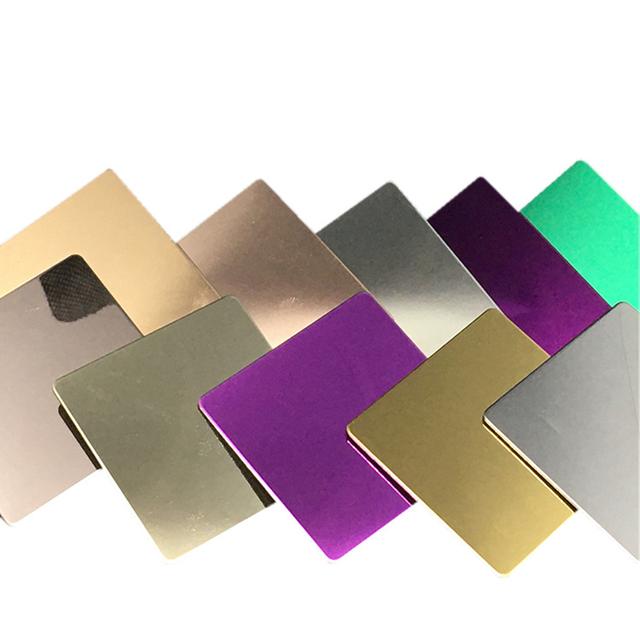

Sandblasted Stainless Steel Sheet is a surface treatment method that treats the surface of stainless steel by spraying a high-speed stream of particles (usually sand) to create a frosted effect. This treatment method can give the stainless steel sheet a unique texture and appearance, which is modern and artistic.

In the manufacture of sandblasting stainless steel plates, sand or other hard particles are used, and the particles are hit to the surface of the stainless steel by high-speed jetting, thereby producing a frosted effect.

Features of this treatment are similar to those of bead blasted stainless steel, including:

1. Unique Appearance: Grit blasting creates an even, frosted appearance on stainless steel surfaces, giving texture and texture to the material.

2. Covering blemishes: Sandblasting can cover up small blemishes, scratches and fingerprints on the stainless steel surface, making the surface look more uniform.

3. Artistic:The appearance of sandblasting stainless steel plate can be changed according to different sandblasting techniques and particle selection, thus creating a variety of artistic effects.

4. Wide Applicability: Sandblasted stainless steel sheet is suitable for indoor and outdoor decorative applications, such as wall decoration, furniture, doors and windows, etc.

Size and Thickness of Sandblasted Stainless Steel Sheet:

Size : The dimensions of sandblasted stainless steel sheets can be customized as required, and usually vary within the following ranges:

Length: Common lengths range from 1000mm to 6000mm, but longer sizes can be customized as required.

Width: Generally between 1000mm and 1500mm, it can also be adjusted according to the needs of the project.

Thickness: The thickness of the blasted stainless steel plate can also vary according to project requirements, common thickness ranges include:

Thin plate: usually between 0.3mm and 3.0mm.

Medium and thick plate: generally between 3.0mm and 6.0mm.

Thick plate: The thickness can exceed 6.0mm, and the specific thickness depends on the needs of the project.

Process of Sandblasted Stainless Steel Sheet:

The process of manufacturing grit blasted stainless steel sheet involves multiple steps, the following is a general overview of the production process:

Material preparation: Select a suitable stainless steel plate as the base material. Stainless steel materials such as 304 and 316 are usually used, and different alloys and specifications can be selected according to needs.

Surface Cleanliness: Make sure the stainless steel surface is clean and free of grease, impurities and stains. Commonly used cleaning methods include chemical cleaning and mechanical cleaning.

Particle selection: Select the appropriate particle material, usually sand or other hard particles. The size and hardness of the particles will affect the final matte finish.

Blasting process: The selected particles are loaded into a blasting machine or blasting booth. The stainless steel plate is placed in the sandblasting chamber, and the particles are hit to the surface of the stainless steel by spraying a high-speed particle stream, thereby forming a frosted effect. Control the intensity, direction and duration of the spray to achieve the desired matte depth and look.

Sanding Depth Control: Adjust the parameters of the spray, such as spray time, particle size and pressure, to control the depth of the sanding. Longer spray times and larger particles create a deeper matte finish.

Cleaning and inspection: After sandblasting is completed, the stainless steel plate needs to go through cleaning and inspection steps to remove residual particles and impurities to ensure that the surface quality meets the requirements.

Anti-corrosion treatment (optional): According to needs, anti-corrosion treatment can be carried out on the sandblasted stainless steel plate to improve its corrosion resistance.

Packing and Shipment: After all the processing is done, the sandblasted stainless steel panels are packed and ready for shipment from the factory.

Application areas of Sandblasted Stainless Steel Sheet:

Sandblasted stainless steel sheets are versatile materials that find applications in various industries due to their unique aesthetic and functional properties. Here are some common application areas for sandblasted stainless steel sheets:

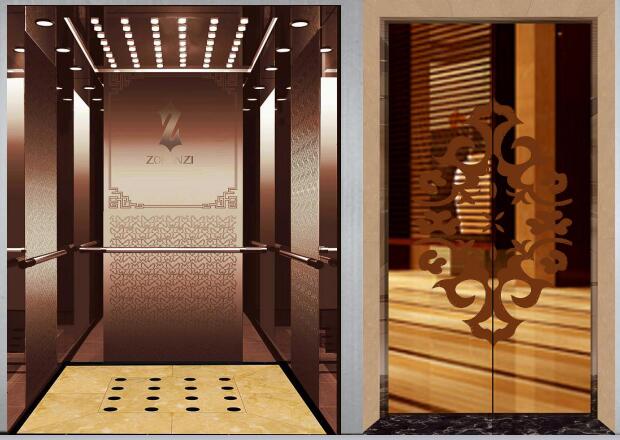

1. Interior Design: Sandblasted stainless steel sheets are widely used in interior design to create modern and stylish spaces. They can be used for wall cladding, decorative panels, room dividers, and other design elements to add texture and visual interest.

2. Architectural Features:These sheets are often used in architectural projects to enhance the appearance of buildings. They can be incorporated into facades, columns, and other architectural elements to create a distinctive and contemporary look.

3. Furniture: Sandblasted stainless steel sheets can be used in furniture design to add a touch of sophistication. They can be used for table tops, countertops, cabinet doors, and other furniture pieces, providing a unique texture and surface finish.

4. Kitchen and Bathroom:In residential and commercial settings, sandblasted stainless steel sheets are employed for kitchen and bathroom applications. They can be used for backsplashes, countertops, and sink surrounds to achieve a modern and elegant look.

5. Retail and Commercial Spaces: These sheets are used in retail and commercial spaces to create eye-catching displays, wall coverings, and signage. Their textured appearance can help draw attention and contribute to the overall ambiance of the space.

6. Hospitality Industry:Sandblasted stainless steel sheets are utilized in hotels, restaurants, and bars to enhance the interior design. They can be used for decorative wall panels, bar fronts, and other design elements that contribute to the overall atmosphere.

7. Elevators and Escalators:Elevators and escalators often incorporate sandblasted stainless steel sheets for their interior surfaces. The textured finish can add a touch of luxury to these functional elements.

8. Exhibition Stands:In trade shows and exhibitions, sandblasted stainless steel sheets can be used to create attention-grabbing displays and booths, adding a unique visual element to the exhibition.

9. Automotive Accessories:Sandblasted stainless steel sheets can be used in the automotive industry for interior and exterior trim, such as dashboard panels, door handles, and decorative accents.

10. Art and Sculptures:Artists and sculptors can utilize sandblasted stainless steel sheets to create textured surfaces in their artworks, sculptures, and installations.

It’s important to note that the application areas are not limited to the examples mentioned above. Sandblasted stainless steel sheets offer a wide range of possibilities due to their aesthetic appeal, durability, and ability to add depth to various surfaces. The choice of application area depends on the specific project requirements and the desired visual impact.

Post time: Aug-21-2023