201 304 316 PVDF Color Decorative Stainless Steel Paint Sheet For Cabinets

Simply put, it consists of two core parts:

Base material: stainless steel plate. Commonly used grades are 304, 304L, 316, 316L, 201, 430, etc., which are selected according to the application environment and cost requirements. Stainless steel provides excellent strength, toughness, corrosion resistance (especially the base layer) and fire resistance.

Surface layer: baking paint coating. Usually composed of primer, color paint (topcoat) and sometimes clear varnish. Under high temperature (usually between 150°C - 250°C), the resin in the paint cross-links and solidifies to form a hard, dense, uniformly colored, high-gloss paint film that is firmly attached to the metal surface.

-

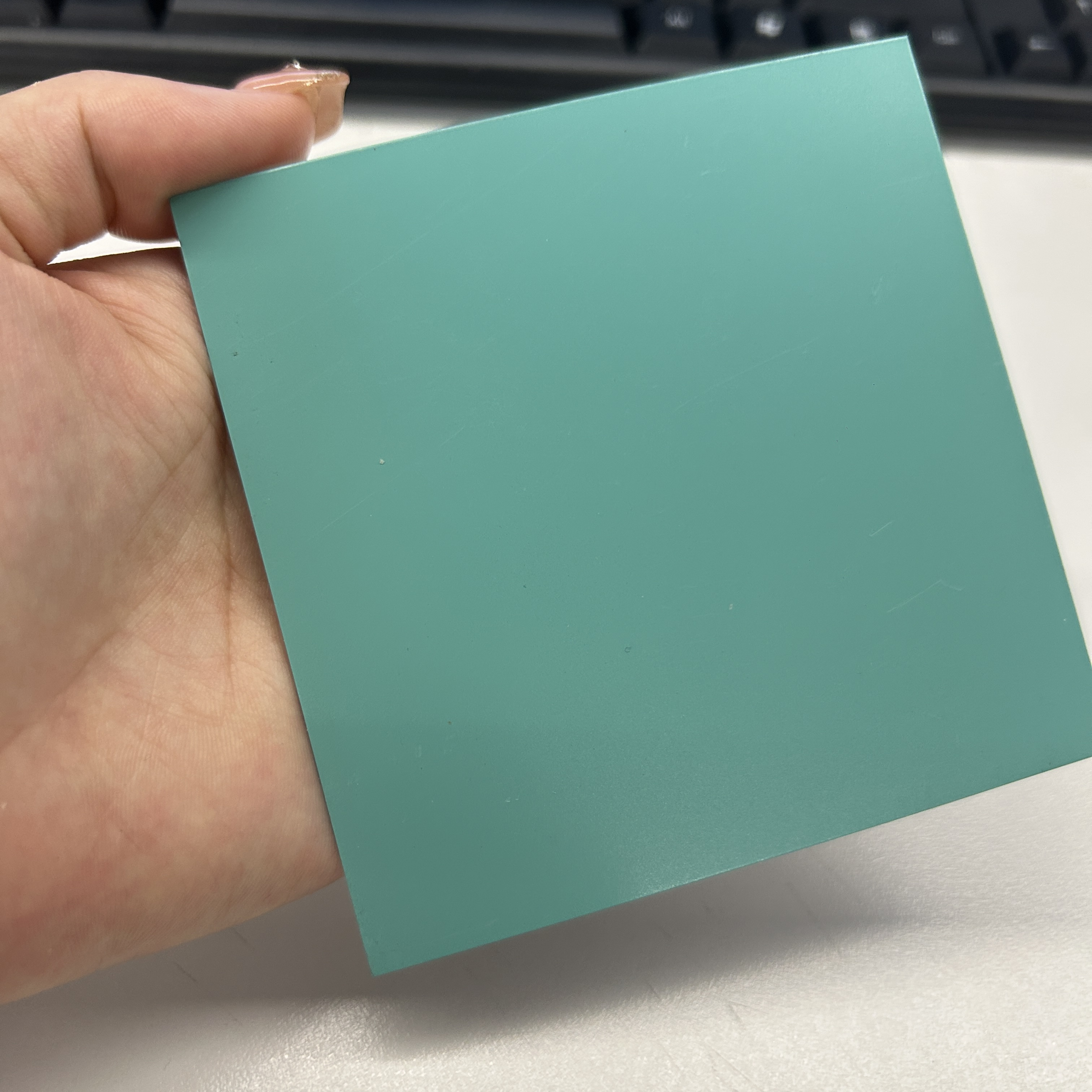

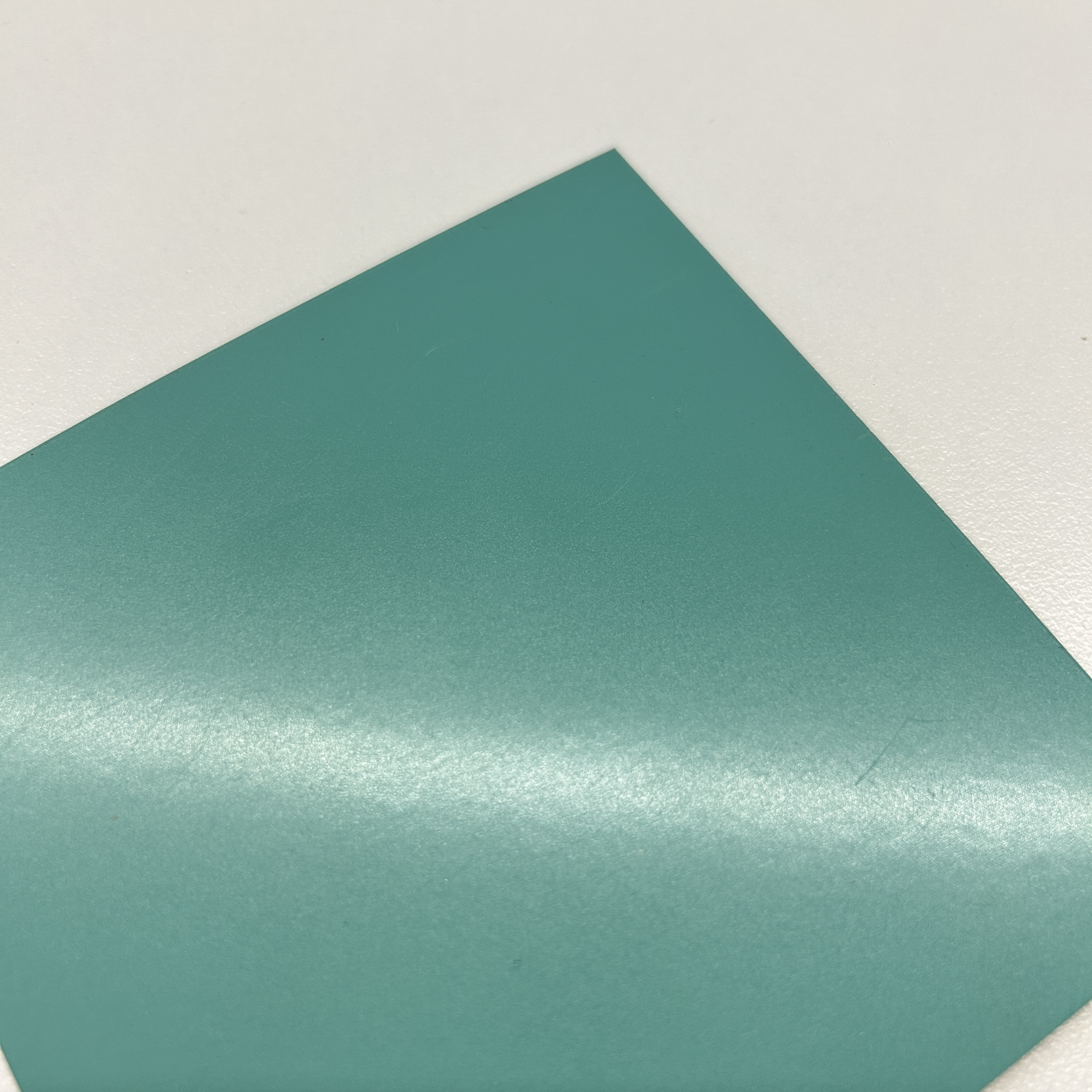

Rich and diverse colors and gloss: This is its most prominent advantage. Almost any color (RAL color card, Pantone color card, etc.) and a variety of effects such as high gloss, matte, metallic paint, pearlescent paint, imitation wood grain, imitation stone grain, etc. can be provided to meet various design needs.

-

Excellent surface flatness and smoothness: After spraying and baking process, the surface is very flat and smooth, easy to clean, not easy to hide dirt, and the visual effect is high-end.

-

Enhanced corrosion resistance: The high-quality paint layer itself has good chemical resistance (acid and alkali resistance, solvent resistance) and weather resistance (UV resistance, humidity and heat resistance), providing an additional protective barrier for the stainless steel substrate, so that it can maintain a good appearance in more demanding environments. Especially for stainless steel with relatively poor corrosion resistance such as 201, the paint layer can significantly improve its overall anti-rust ability.

-

Good scratch and wear resistance: The paint film after high temperature curing has a higher hardness, and is less likely to be scratched or worn than ordinary spraying or PVC film (but not absolutely scratch-proof).

-

Easy to clean and maintain: The smooth and dense surface makes it difficult for oil, dust, etc. to adhere. Just wipe it with a damp cloth or neutral detergent on a daily basis.

-

Environmental protection: Modern baking paint processes mostly use environmentally friendly coatings (such as fluorocarbon coatings PVDF, polyester coatings PE, etc.), with low VOC emissions.

- Retain some characteristics of stainless steel: such as strength, fire resistance (Class A non-combustible materials), and certain high temperature resistance (depending on the type of paint).

- Cost-effectiveness: Compared with complex processes such as pure stainless steel etching and embossing, or using higher-grade stainless steel (such as 316) to achieve better appearance and corrosion resistance, baking paint is a relatively economical and efficient way to achieve rich colors and surface effects.

Application fields of stainless steel paint plate

Due to its beautiful, durable and easy-to-clean characteristics, stainless steel paint plate is widely used in:

Architectural decoration: indoor and outdoor curtain walls, wall decoration panels, elevator cars, door covers, column wraps, ceilings, sunshades, etc.

Kitchen equipment: high-end cabinet door panels, refrigerator panels, range hood panels, disinfection cabinet panels, commercial kitchen equipment shells, etc.

Household appliances: washing machine panels, dryer panels, microwave oven panels, water heater panels, etc.

Furniture: office furniture, bathroom furniture, display cabinets, bar counters, etc.

Transportation: interior decoration panels of subways, high-speed railways, ships, and buses.

Advertising logos: sign base plates, display racks.

Other industrial uses: clean room walls, laboratory countertops, equipment shells, etc.

Difference from ordinary spraying

"Baking" is the key: ordinary spraying may only be naturally dried or low-temperature baked, the cross-linking curing degree of the paint film is low, and the hardness, adhesion, and durability are far inferior to the paint cured by high-temperature baking.

Performance difference: Paint panels are usually much better than ordinary spray panels in terms of weather resistance, chemical resistance, hardness, wear resistance, adhesion, gloss durability, etc.

Aspects to note

Paint film damage: If the paint film is severely scratched or damaged due to bumps, the internal steel plate is exposed, and rust may still occur in this place under harsh conditions (although stainless steel itself is corrosion-resistant, the damaged edge may still become the starting point of corrosion).

Cost: Compared with ordinary stainless steel plates or spray panels, paint panels are more expensive.

Installation and handling: Careful operation is required to avoid bumps and scratches on the surface.

High temperature limit: Although the substrate is stainless steel, the paint layer has its upper temperature limit (usually not more than 150°C - 200°C, depending on the type of paint). Long-term high temperature will cause the paint film to discolor, powderize or even fall off.

Summary

Painted stainless steel sheet is a functional decorative sheet that perfectly combines the practical properties of stainless steel (strength, corrosion resistance, fire resistance) with the aesthetic decorative properties of paint (rich colors, gloss, flatness). It is widely used in construction, home appliances, home furnishing and industrial fields that have high requirements for beauty, durability and easy cleaning. When choosing, you need to pay attention to the material of the stainless steel substrate, the type of paint coating (such as PVDF fluorocarbon paint has the best weather resistance) and the quality of the processing technology.

Parameters:

|

Type

|

Stainless steel paint plate |

| Thickness | 0.3 mm - 3.0 mm |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max. width 1500mm |

| SS Grade | 304,316, 201,430, etc. |

| Origin | POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc. |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

4. What substrates are PVDF coatings applied to?

A4: Primarily:

A5: Extremely durable, PVDF coatings are known for their ability to withstand decades of harsh weather exposure while retaining color and gloss significantly better than polyester (PE) or silicone-modified polyester (SMp) coatings. Lifespans of 20+ years are common.

6. Does PVDF coating fade?

A8: Yes, PVDF coating is typically the most expensive option among common coil coatings (PE, SMP, PVDF) due to the higher cost of the fluoropolymer resin and premium pigments.

Foshan Hermes Steel Co., Limited, establishes a large stainless steel comprehensive service platform integrating international trading, processing, storage and after-sales service.

Our company is located in Foshan Liyuan Metal Trading Center, which is a large stainless steel distribution and trading area in southern China, with convenient transportation and mature industrial supporting facilities. A lot of merchants gathered around the market center. Combining the advantages of market location with strong technologies and scales of major steel mills, Hermes Steel takes full advantages in the field of distribution and quickly shares market information. After more than 10 years of unremitting operation, Hermes Steel establishes professional teams of international trading, large warehousing, processing and after-sales service, providing professional stainless steel import and export trading services to our international customers with fast response, stable supreme quality, strong after-sales support and excellent reputation.

Hermes Steel has a wide range of products and services, covering stainless steel coils, stainless steel sheets, stainless steel pipes, stainless steel bars, stainless steel wires and customized stainless steel products, with steel grades 200 series, 300 series, 400 series; including surface finish like NO.1, 2E, 2B, 2BB, BA, NO.4, 6K, 8K. In addition to meet the individual needs of our customers, we also provide customized 2BQ (stamping material), 2BK (8K processing special material) and other special material, with customized surface’s processing including mirror, grinding, sandblasting, etching, embossing, stamping, lamination, 3D laser, antique, Anti-fingerprint, PVD vacuum coating and water plating. At the same time, we provide with flattening, slitting, film covering, packaging and full sets of import or export trading services.

Foshan Hermes Steel Co., Limited. with years of experience in the field of stainless steel distribution, has been adhering to the aims of customer focus and service orientation, continuously building a professional sales and service team, providing professional solutions to satisfy customers’ various demands through prompt response and ultimately obtaining customer satisfaction to reflect the value of our enterprise. Our mission is to be a stainless steel company providing one-stop service to promptly satisfy the customers’ requirements.

In the process of providing customers with quality products and services for many years, we have gradually established our own corporate culture. Believing, sharing, altruism and persisstence are the pursuits of every staff from Hermes Steel.