wholesale high quality 201 304 316 8K mirror pvd colored etched stainless steel sheet and plates used for elevator door

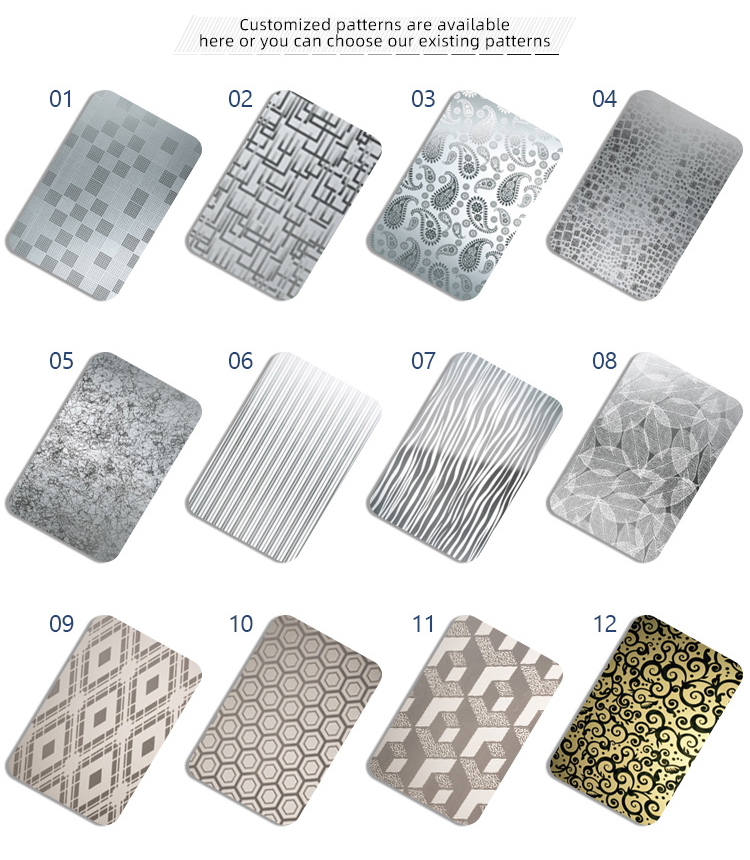

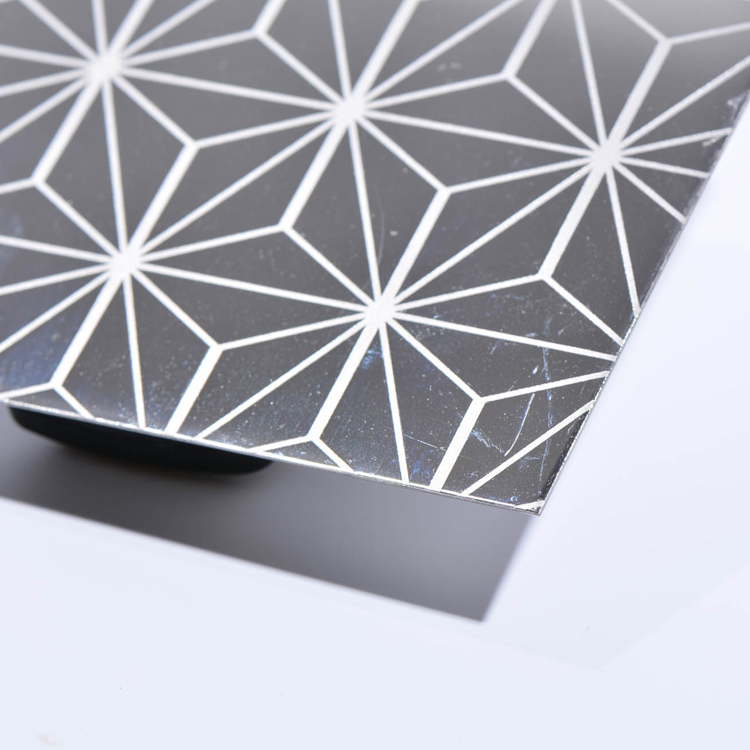

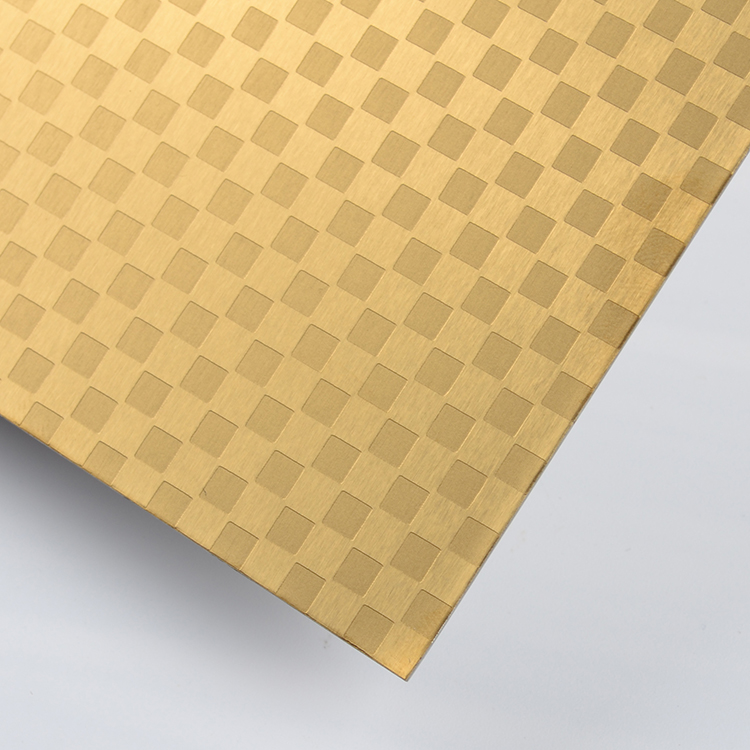

The etching removes a thin layer of stainless steel, changes the color to a dull silver gray, and roughens the surface, which can be contrasted with grinding, super mirror, or other finishes to create thousands of variations. The etched finish also can be colored before or after etching.

|

Type |

4x8 decorative stainless steel sheet |

|

Name |

ATEM 304 0.8mm 1mm 4x8ft' etched pvd color stainless steel sheets ltd for exterior brick wall panels |

|

Thickness |

0.3-3mm |

|

Size |

1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max. width 1500mm |

|

SS Grade |

304,316, 201,430, etc. |

|

Finish |

etching |

|

Available finishes |

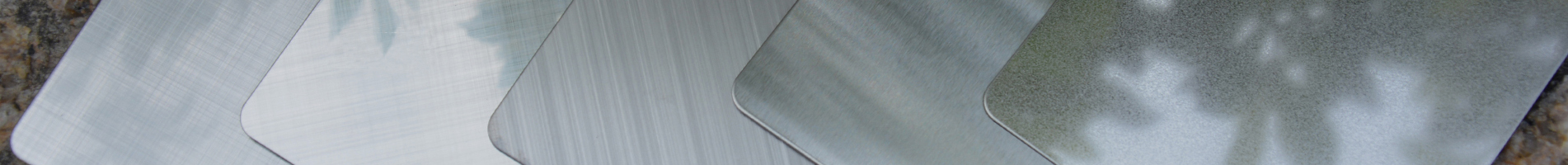

No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination, etc. |

|

Origin |

POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc. |

|

Packing way |

PVC+ waterproof paper + strong sea-worthy wooden package |

|

Chemical composition |

||||

|

Grade |

STS304 |

STS 316 |

STS430 |

STS201 |

|

Elong(10%) |

Above 40 |

30MIN |

Above 22 |

50-60 |

|

Hardness |

≤200HV |

≤200HV |

Below 200 |

HRB100,HV 230 |

|

Cr(%) |

18-20 |

16-18 |

16-18 |

16-18 |

|

Ni(%) |

8-10 |

10-14 |

≤0.60% |

0.5-1.5 |

|

C(%) |

≤0.08 |

≤0.07 |

≤0.12% |

≤0.15

|

Etching a stainless steel sheet is a process of creating designs, patterns, or textures on the surface of stainless steel using an etching technique. The etching process involves selectively removing the material from the stainless steel sheet to create the desired design.

Here is a general overview of the etching process for stainless steel:

Design: Start by creating or selecting the procedure or pattern you want to etch onto the stainless steel sheet. This can be done using computer-aided design (CAD) software or by hand.

Masking: Apply a mask or resist material, such as a vinyl sheet or photoresist, onto the stainless steel sheet. The mask protects the areas you want to remain untouched during the etching process.

Transfer: Transfer the design onto the mask using a technique like screen printing or by exposing the mask to UV light through a photomask, depending on the complexity of the design.

Etching: Submerge the stainless steel sheet into an etchant solution, which is typically an acid-based chemical. The etchant selectively removes the unprotected metal, creating the desired design. Common etchants for stainless steel include nitric acid or a mixture of nitric and hydrochloric acids (aqua regia).

Rinse and Clean: Once the desired etching depth is achieved, remove the stainless steel sheet from the etchant solution and rinse it thoroughly with water to stop the etching process. Clean the surface to remove any remaining mask or residue.

Finishing: After etching, you may choose to further enhance the appearance of the stainless steel sheet by applying various finishing techniques. These can include polishing, brushing, or coating the surface to add color or protect the etched design.

It's important to note that etching stainless steel requires proper safety precautions due to the use of chemicals. It is advisable to work in a well-ventilated area, wear appropriate protective gear (gloves, goggles, and a respirator), and follow the manufacturer's instructions for handling the etching chemicals.

Foshan Hermes Steel Co., Limited, establishes a large stainless steel comprehensive service platform integrating international trading, processing, storage and after-sales service.

Our company is located in Foshan Liyuan Metal Trading Center, which is a large stainless steel distribution and trading area in southern China, with convenient transportation and mature industrial supporting facilities. A lot of merchants gathered around the market center. Combining the advantages of market location with strong technologies and scales of major steel mills, Hermes Steel takes full advantages in the field of distribution and quickly shares market information. After more than 10 years of unremitting operation, Hermes Steel establishes professional teams of international trading, large warehousing, processing and after-sales service, providing professional stainless steel import and export trading services to our international customers with fast response, stable supreme quality, strong after-sales support and excellent reputation.

Hermes Steel has a wide range of products and services, covering stainless steel coils, stainless steel sheets, stainless steel pipes, stainless steel bars, stainless steel wires and customized stainless steel products, with steel grades 200 series, 300 series, 400 series; including surface finish like NO.1, 2E, 2B, 2BB, BA, NO.4, 6K, 8K. In addition to meet the individual needs of our customers, we also provide customized 2BQ (stamping material), 2BK (8K processing special material) and other special material, with customized surface’s processing including mirror, grinding, sandblasting, etching, embossing, stamping, lamination, 3D laser, antique, Anti-fingerprint, PVD vacuum coating and water plating. At the same time, we provide with flattening, slitting, film covering, packaging and full sets of import or export trading services.

Foshan Hermes Steel Co., Limited. with years of experience in the field of stainless steel distribution, has been adhering to the aims of customer focus and service orientation, continuously building a professional sales and service team, providing professional solutions to satisfy customers’ various demands through prompt response and ultimately obtaining customer satisfaction to reflect the value of our enterprise. Our mission is to be a stainless steel company providing one-stop service to promptly satisfy the customers’ requirements.

In the process of providing customers with quality products and services for many years, we have gradually established our own corporate culture. Believing, sharing, altruism and persisstence are the pursuits of every staff from Hermes Steel.