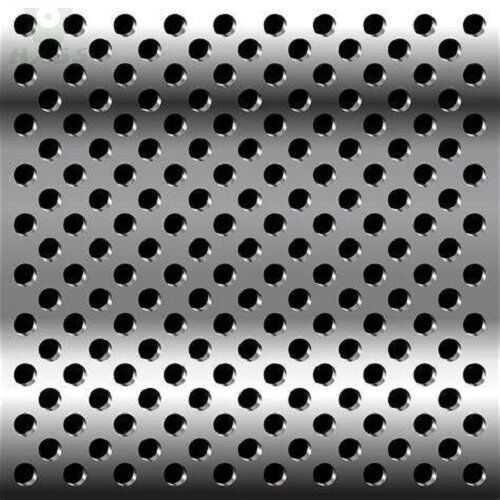

Kukho iintlobo ezininzi kunye neenkcukacha zeepleyiti zensimbi ezingenasici. Ipleyiti ene-perforated inobunzima obuhle kwaye ayiyi konakala emva kwexesha elithile. Ukongeza, ipleyiti enemingxuma intle kwaye inesisa. Zikwasetyenziswa kwizinto ezininzi zobomi bokwenene, ezifana nesamente, ukukhuselwa kwendalo, ukuhlobisa, njl. Ubomi abuyi kungcoliswa. Ubungakanani kunye nobukhulu bepleyiti enemingxuma ingenziwa ngokwezifiso ngokweemfuno zabathengi.

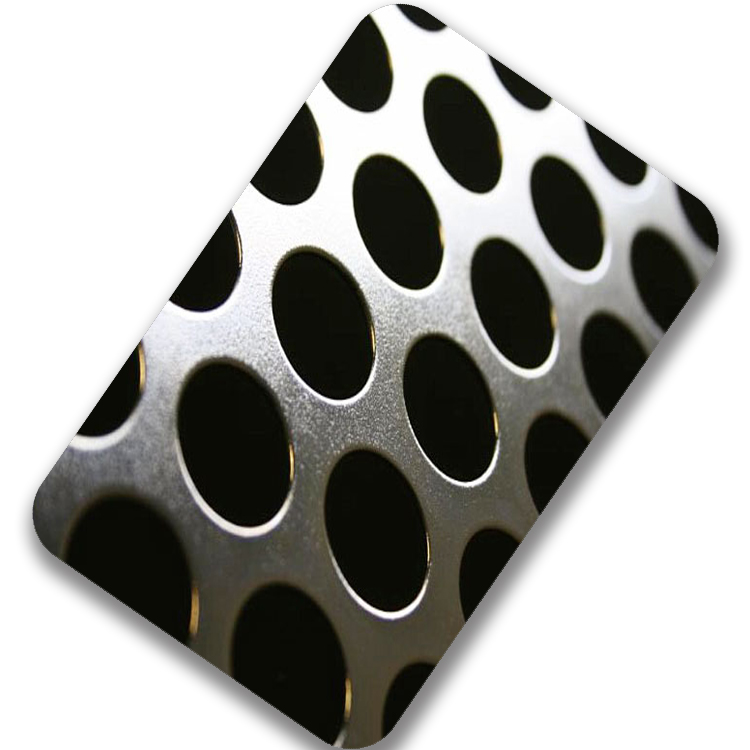

Insimbi engenasici luhlobo lwemesh yensimbi eyenziwe ngokubetha iipleyiti zensimbi ezingenasici kumatshini wokubhoboza we-CNC ngokwendlela yokubeka umngxuma. Iipleyiti zidla ngokuba ziipleyiti zentsimbi ezikumgangatho ophezulu ezinje nge-SUS361, SUS304, kunye ne-SUS201. Iindidi zemingxuma zinemingxuma ejikelezayo, imingxuma emide ejikelezayo, imingxuma yesikwere, imingxuma engunxantathu, imingxuma yesikali, imingxuma yedayimane, imingxuma ye-herringbone, imingxuma emide esinqeni, imingxuma yeentyatyambo zeplum, imingxuma e-I-shaped, kunye neminye imingxuma ekhethekileyo.

Olona phawu lukhulu lwepleyiti enemingxuma yensimbi engenastainless kukuba inobunzima obukhaphukhaphu, inokumelana nefuthe elinamandla, ukusebenza kakuhle kokucoca, inkangeleko entle, kunye neepatheni ezahlukeneyo.

Isetyenziswa kakhulu kwimizi-mveliso kwaye isetyenziselwa oohola bendlela, oololiwe, oololiwe kunye nezinye iindlela zokuhamba kwiindawo zasezidolophini Izithintelo zokulawula ingxolo yokusingqongileyo kwizibonelelo, iipaneli ezifunxa isandi sokugquma isandi kunye nokunciphisa ingxolo kwiindonga zesakhiwo, amagumbi e-generator, izakhiwo zefektri, kunye neminye imithombo yengxolo, inokusetyenziswa njengezinto ezifunxa isandi kwisakhiwo sophahla kunye neepaneli zodonga.

Isithethi esihle, i-grinders, izikrini zasemgodini, izikrini ezimilise okwengqolowa, ukutya, imigodi, iibhaskithi zeziqhamo zentsimbi, izigqubuthelo zokutya, iipleyiti zeziqhamo, kunye nezinye izitya zasekhitshini zezixhobo zasekhitshini, kunye neminatha yeshelufu yeendawo zokuthenga, imiboniso yokuhombisa, kunye neminatha yokungenisa umoya kunye ne-ventilation yamanzi kwi-waret field nets.

Kukho iintlobo ezininzi kunye neenkcukacha zeepleyiti zensimbi ezingenasici. I-perforated mesh yensimbi engenasici inobunzima obuhle kwaye ayiyi konakala emva kwexesha elithile. Ukongeza, ipleyiti yensimbi engenasici intle kwaye inesisa. Zikwasetyenziswa kwizicelo ezininzi zobomi bokwenyani, njengesamente, ukukhuselwa kwendalo, umhlobiso, njl.

Ubomi abuyi kungcoliswa. Ubungakanani kunye nobukhulu beplate yensimbi engenasici ingenziwa ngokwezifiso ngokweemfuno zabathengi. Iimveliso eziveliswe yi-Shanghai Huaxiao Metal Co., Ltd. zigqibelele kakhulu. Iipleyiti zensimbi ezingenasici eziveliswe yinkampani yethu zinomgangatho othembekileyo kunye noqoqosho. Abathengi baya kwenza ngokweemfuno zethu kwaye babakhonze nge-100% yokwaneliseka kunye nengqibelelo. Ukuba unazo naziphi na iimfuno, nceda ukhululeke ukunxibelelana nam. Ngokungakumbiiimveliso zentsimbi engatyiwa,nceda ujonge iwebhusayithi yethu.

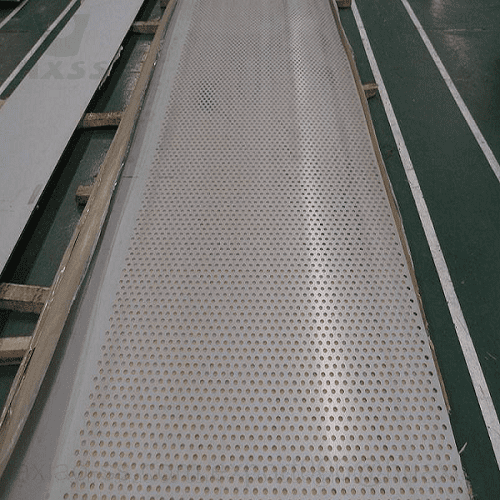

Inkqubo yokuvelisa ipleyiti enemingxuma yentsimbi engenastainless:

I-1, Okokuqala khetha izinto eziphathekayo ze-mesh yensimbi engenasici kwaye uyilo ngokuchanekileyo i-mold ekuqaleni kwe-punching plate / i-perforated mesh yensimbi engenasici. Umgangatho wokufa umisela umgangatho wemveliso ye-mesh yensimbi engenasici kwi-perforated kwiprogram enkulu, ngoko siye sabetha kwiminyaka yamuva. Umngundo utyale imali eninzi kunye namandla, nto leyo eye yaphucula kakhulu uyilo lokubumba kunye nomthamo wokuvelisa wefektri yethu kwaye yaqokelela iipateni zokubumba.

Ukubetha: Ngoku iveliswa sesona sixhobo siphambili se-wkc-2000 CNC eTshayina. I-Stepper motor feeding kunye nokulawula ukusebenza kwe-plc, ukuchaneka kwemveliso kufikelela ku-+/-0.15MM, kunye nolawulo olusemgangathweni, lunokuthi lufakwe isitampu kuluhlu lwe-10mm-0.2mm.

I-2, ukuchetywa kwebhodi: Ukuba umda wenkqubo yokuvelisa udlula uluhlu lonyamezelo olufunayo, amagcisa ethu anezakhono anokukunceda ukuba ususe imiphetho engaphezulu ngokweemfuno zakho;

I-3, ukusika ibhodi: ukusika kumqulu wonke webhodi kwisayizi oyifunayo;

4. Ukulungiswa kwe-mesh ye-perforated stainless steel mesh: Singasebenzisa umatshini wokulinganisa ukubuyisela ipleyiti ephothiweyo ye-punched deformation kwisimo sayo sokuqala.

Iipleyiti ze-Stainless Steel ezinobunzima obuyi-0.8mm-12mm zinokubekwa kwinqanaba. Kwaye ukucoca i-punching kufuna ukusetyenziswa kwee-lubricants, kodwa sinenkqubo yokunciphisa i-degreasing esusa umkhondo ukusuka phezulu kwaye yenza i-orifice icoceke. Ukuqulunqa kunye nokusebenza okunzulu, ukongeza kugcino lwabathengi, sinokubonelela ngoluhlu lwenkqubo elandelayo kwipleyiti yensimbi engenasici, ebandakanya ukulinganisa, ukusika, ukuleyibhela, ukupakishwa, ukukhupha amafutha, ukukhupha, ukubumba, ukudibanisa, ukupeyinta, i-electroplating, i-welding, i-Polishing, ukugoba, ukuqengqeleka, njl.

Ixesha lokuposa: Nov-30-2022