Isiphumo sesibuko sensimbi engenasici sibhekiselele ekukhanyeni okuphezulu, okufana nesipili esifunyenwe kumphezulu wamaphepha ensimbi. Esi siphumo sisiphumo senkqubo ekhethekileyo yokupholisha kunye ne-buffing eyenza indawo egudileyo, ekhanyayo kunye neqondo eliphezulu lokubonakala.

Inkqubo yokuPhumeza isiphumo sesipili

Ukukhethwa kwezinto:

Imigangatho ephezulu yensimbi engenasici efana ne-304, i-316, okanye i-430 isetyenziswa ngokuqhelekileyo.

La mabanga akhethelwe ukuxhathisa okugqwesileyo kokutya, ukuqina, kunye nokukwazi ukugudiswa kwi-sheen ephezulu.

Ukugudisa:

Umphezulu wensimbi engenasici utyhutyha uthotho lwamanyathelo okusila kunye nokupholisha kusetyenziswa i-abrasives eyongezelelekileyo.

Le nkqubo isusa ukungafezeki, imikrwelo, kunye nezitenxo zomphezulu, nto leyo ekhokelela kwindawo egudileyo, efanayo.

Ukubhufa:

Emva kokupholishwa, intsimbi engatyiwayo iyagqunywa kusetyenziswa izinto ezithambileyo kunye neekhompawundi zokuphucula ukukhanya kunye nokufezekisa ukugqiba okubonakalayo.

I-buffing iqhubela phambili igudisa umphezulu kwaye inyuse ukukhazimla kwayo, idala inkangeleko efana nesipili.

Iimpawu zeMirror Effect

Ukuzibonakalisa:

Isiphumo sesibuko siphumela kwindawo enokubonisa imifanekiso kunye nokukhanya okuphantse kufane nesibuko seglasi.

Oku kubonakaliswa kuphezulu kungenxa yokuguda kunye nokulingana komphezulu okuphunyezwe ngokulungiswa ngobuchule.

Isibheno sobuhle:

Ukugqitywa okufana nesipili kubukeka kunomtsalane kwaye yongeza ukubanjwa kobuhle kunye nobugocigoci kwizicelo ezahlukeneyo.

Ihlala isetyenziselwa izinto zokuhlobisa kunye nezakhiwo zokwakha imbonakalo yanamhlanje kunye nephezulu.

Umphezulu oGudile:

Umphezulu wentsimbi egqwethiweyo yesipili ugudile kakhulu, unoburhabaxa obuphantsi kakhulu.

Oku kuguda akupheleli nje ekubeni negalelo kumgangatho obonakalisayo kodwa kwenza umphezulu ube lula ukuwucoca nowokugcina.

Ukubunjwa kweekhemikhali zensimbi engenasici kuyahluka ngokuxhomekeka kwibakala elithile kunye nokusetyenziswa kwayo. Nazi iinkcukacha zokwakheka kweekhemikhali zamabakala aqhelekileyo entsimbi engatyiwayo:

304 Intsimbi engatyiwa

I-304 Stainless Steel yeyona isetyenziswa ngokuqhelekileyo i-austenitic stainless steel, eyaziwa ngokumelana nokugqwesa kwayo okugqwesileyo kunye nokubumba. Ukwakhiwa kweekhemikhali ngokuqhelekileyo kubandakanya:

- Ikhabhoni (C): ≤ 0.08%

- IManganese (Mn): ≤ 2.00%

- Isilicon (Si): ≤ 0.75%

- I-Chromium (Cr): 18.00% - 20.00%

- I-Nickel (Ni): 8.00% - 10.50%

- Phosphorus (P)≤ 0.045%

- Isulfure (S): ≤ 0.030%

316 Intsimbi engatyiwa

I-316 i-Stainless Steel iqulethe i-molybdenum, eyandisa ukuxhathisa kwayo kwi-kloride corrosion, iyenze ifanelekele iindawo zaselwandle kunye nezixhobo zokulungisa imichiza. Ukwakhiwa kweekhemikhali ngokuqhelekileyo kubandakanya:

- Ikhabhoni (C): ≤ 0.08%

- IManganese (Mn): ≤ 2.00%

- Isilicon (Si): ≤ 0.75%

- I-Chromium (Cr): 16.00% - 18.00%

- I-Nickel (Ni): 10.00% - 14.00%

- I-Molybdenum (Mo): 2.00% - 3.00%

- Phosphorus (P)≤ 0.045%

- Isulfure (S): ≤ 0.030%

430 iNtsimbi eNgatyiwayo

I-430 Stainless Steel iyinsimbi engenasici ye-ferritic eyaziwa ngokuxhathisa kwayo kakuhle kunye nokubumba kodwa ayinakho ukusebenza okuphezulu kobushushu kunye nokumelana nokunyuka kwe-304 kunye ne-316. Ukubunjwa kwayo kweekhemikhali kubandakanya:

- Ikhabhoni (C): ≤ 0.12%

- IManganese (Mn): ≤ 1.00%

- Isilicon (Si): ≤ 1.00%

- I-Chromium (Cr): 16.00% - 18.00%

- I-Nickel (Ni): ≤ 0.75%

- Phosphorus (P): ≤ 0.040%

- Isulfure (S): ≤ 0.030%

201 Intsimbi engatyiwa

I-201 iStainless Steel yintsimbi ye-austenitic engatyiwayo ene-manganese ephezulu kunye nomxholo we-nitrogen ukuze ithathe indawo ye-nickel, esetyenziswa ngokuqhelekileyo kwindawo epholileyo enomhlwa. Ukwakhiwa kweekhemikhali ngokuqhelekileyo kubandakanya:

- Ikhabhoni (C): ≤ 0.15%

- IManganese (Mn): 5.50% - 7.50%

- Isilicon (Si): ≤ 1.00%

- I-Chromium (Cr): 16.00% - 18.00%

- I-Nickel (Ni): 3.50% - 5.50%

- Phosphorus (P)≤ 0.060%

- Isulfure (S): ≤ 0.030%

- I-nitrogen (N): ≤ 0.25%

410 intsimbi engatyiwa

I-410 Stainless Steel yintsimbi ye-martensitic enamandla amakhulu kunye nokuqina kodwa ukuxhathisa okuphantsi kwe-corrosion, esetyenziswa ngokuqhelekileyo kwizicelo ezifuna amandla aphezulu. Ukwakhiwa kweekhemikhali ngokuqhelekileyo kubandakanya:

- Ikhabhoni (C): ≤ 0.15%

- IManganese (Mn): ≤ 1.00%

- Isilicon (Si): ≤ 1.00%

- I-Chromium (Cr): 11.50% - 13.50%

- I-Nickel (Ni): ≤ 0.75%

- Phosphorus (P): ≤ 0.040%

- Isulfure (S): ≤ 0.030%

Olu qulunqo lweekhemikhali lumisela iimpawu zokusebenza kwibakala ngalinye lensimbi engenasici, ezifana nokuxhathisa i-corrosion, amandla, ukuqina, kunye ne-machinability. Ngokuxhomekeke kwiimfuno ezithile zesicelo, ibakala elifanelekileyo lensimbi engenasici lingakhethwa ukufezekisa ukusebenza kakuhle.

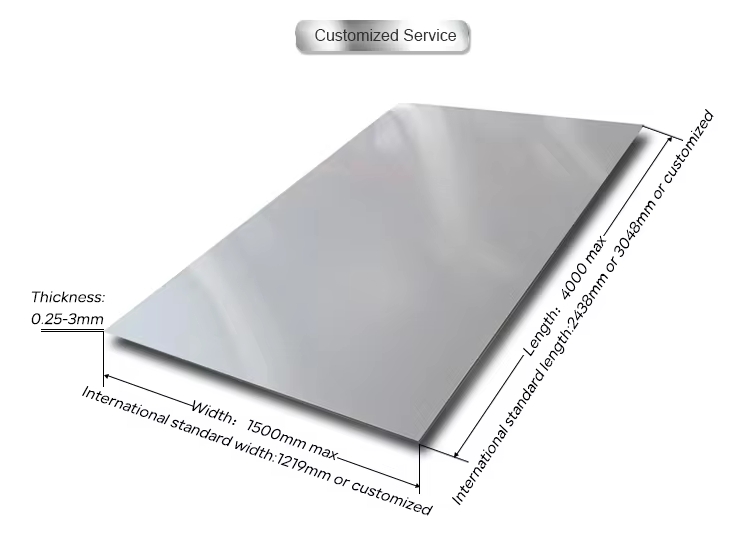

Ubungakanani obusemgangathweni:

Amashiti entsimbi angenasipili afumaneka ngokobukhulu obuqhelekileyo, obunje:

-

Ukutyeba: Ubukhulu obuqhelekileyo buvela kwi-0.25mm ukuya kwi-3mm, kuxhomekeke kwiimfuno zesicelo.

-

Ububanzi: Ububanzi obuqhelekileyo bunokwahluka kwi-1000mm ukuya kwi-1500mm okanye ngaphezulu, kuxhomekeke kumthengisi kunye nenkqubo yokuvelisa.

-

Ubude: Ubude obuqhelekileyo buhlala buvela kwi-2000mm ukuya kwi-4000mm okanye ngaphezulu, kodwa ubude obuqhelekileyo bunokufumaneka.

Ukulungiselela:

Ukuba ubungakanani obuqhelekileyo abuhlangabezani neemfuno zakho, ubungakanani obuqhelekileyo besipili samaphepha entsimbi angenziwa ukuba ahambelane neemfuno zakho ezithile. Oku kuvumela ukuguquguquka okukhulu kuyilo kwaye iqinisekisa ukuba ubungakanani beshiti luhambelana ngokuchanekileyo neemfuno zakho zeprojekthi.

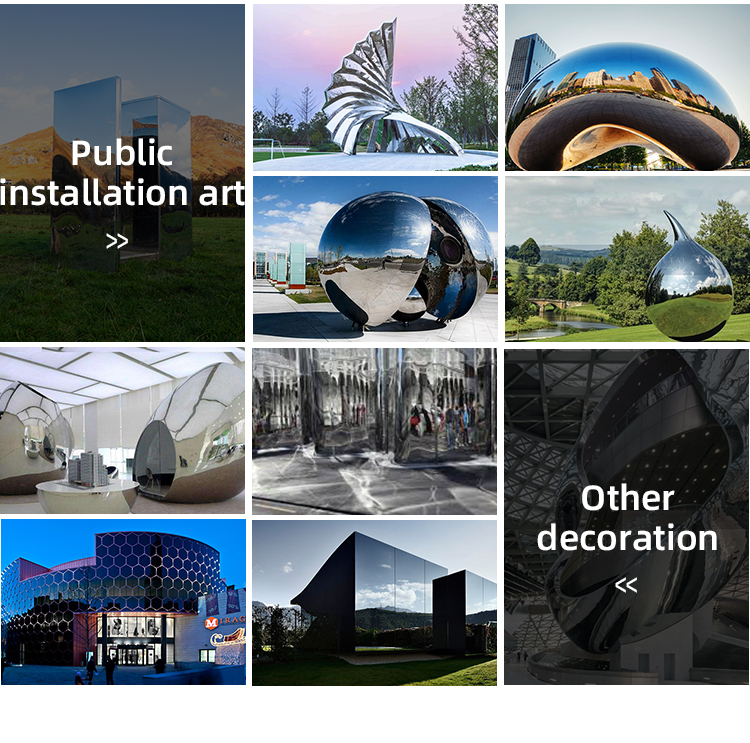

Usetyenziso lweStainless Steel eneMirror Effect

Uyilo lwezakhiwo:

Isetyenziselwa ukwakha i-facades, i-cladding yangaphakathi, kunye neepaneli zokuhombisa.

Ibonelela ngobuhle, ubuhle bale mihla kwaye inokuphucula impembelelo yembonakalo yezakhiwo.

Ukulungiswa ngaphakathi:

Ngokuqhelekileyo isetyenziselwa i-backsplashes yasekhitshini, ii-countertops, kunye neepaneli zodonga.

Yongeza imvakalelo yobumnandi kwiindawo zokuhlala kunye nezorhwebo zangaphakathi.

Iimoto:

Ifakwe kwi-trim, i-grilles, kunye nezinye izinto zokuhombisa izithuthi ukuphucula inkangeleko.

Imiqondiso kunye neZiboniso:

Isetyenziswe kwimiqondiso ephezulu, iipaneli zokubonisa, kunye neebhodi zentengiso ngenxa yesiphumo sayo sokutsala amehlo.

EzoRhwebo kunye nezoShishino:

Isetyenziswa kwiindawo ezifuna amanqanaba aphezulu ococeko, njengezityalo ezilungisa ukutya kunye nezibhedlele, ngenxa yendalo yayo ekulula ukuyicoca.

I-Q1: Yintoni isibuko sentsimbi engenasici?

I-A1: Isibuko seshiti lensimbi engenasici sibhekiselele kwiphepha lensimbi engenasici eliye lafumana inkqubo yokupolisha ekhethekileyo ukuze kuphunyezwe ukugqiba okubonakalayo, okufana nesipili kumphezulu wayo.

Q2:Sifikelelwa njani isibuko kwintsimbi engenasici?

I-A2: Ukugqitywa kwesibuko kwintsimbi engenasici kufezekiswa ngothotho lweenkqubo zokupolisha kunye nokubhobhoza kusetyenziswa iziqhoboshi ezicolekileyo ngokuqhubekayo kude kufumaneke indawo egudileyo, ebonakalisayo.

I-Q3: Zeziphi izicelo zesipili samaphepha ensimbi engenasici?

I-A3: I-Mirror steel stainless sheets isetyenziswa ngokuqhelekileyo kwiiprojekthi zoyilo kunye noyilo lwangaphakathi lokwakha iifacade, iindonga zangaphakathi, iipaneli zokuhombisa, i-backsplashes yasekhitshini, i-countertops, i-automotive trim, imiqondiso kunye nemiboniso.

I-Q4: Ziziphi iingenelo zokusebenzisa i-mirror sheets steel stainless?

I-A4: Izibonelelo zibandakanya i-sleek, i-aesthetic yanamhlanje, ukubonakala okuphezulu, ukuqina, ukuxhathisa ukubola, ukugcinwa lula, kunye nokufaneleka kwezicelo ezahlukeneyo zangaphakathi nangaphandle.

I-Q5: Ngawaphi amabakala ensimbi engenasici asetyenziselwa ukugqiba isibuko?

A5: Amanqaku aqhelekileyo abandakanya i-304, i-316, kunye ne-430 yensimbi engenasici. IBanga lama-316 likhethwa kwizicelo ezifuna ukomelezwa kokumelana nomhlwa, okufana nemekobume yaselwandle.

I-Q6: Ucoca njani kwaye usigcine njani isipili samashiti entsimbi?

I-A6: I-Mirror i-stainless sheet sheets inokucocwa ngokusebenzisa izisombululo ze-detergent ezithambileyo kunye neendwangu ezithambileyo okanye izipontshi. Ziphephe izicoci eziabrasive okanye iipads zokukhuhla ezinokukrwela umphezulu. Ukucoca rhoqo kunceda ukugcina umgangatho obonakalisayo.

I-Q7: Ngaba isibuko samaphepha entsimbi angenziwa ngokwezifiso?

I-A7: Ewe, amashiti ensimbi yesipili angenziwa ngokwezifiso ngokobukhulu, ubukhulu, kunye nokugqiba ukuhlangabezana neemfuno ezithile zeprojekthi. Ukwenza ngokwezifiso kunokubandakanya ukusika, ukubunjwa, okanye ukuhombisa umphezulu ngeenjongo zokuhombisa.

I-Q8: Ngaba amashiti ensimbi yesipili afanelekile kwizicelo zangaphandle?

I-A8: Ewe, isibuko samaphepha ensimbi engenasici sifanelekile kwizicelo zangaphandle, kodwa ukuvezwa kweemeko ezibuhlungu zokusingqongileyo kunokufuna ukucocwa kunye nokugcinwa kwamaxesha ngamaxesha ukugcina ukugqiba.

I-Q9: Yiyiphi imida yesibuko samaphepha ensimbi engenasici?

I-A9: I-Mirror sheet sheets ingabonisa iminwe yeminwe, i-smudges, okanye imikrwelo ngokubonakalayo ngakumbi xa kuthelekiswa nezinye izinto ezigqityiweyo. Ukongezelela, iindleko zokuqala zinokuba phezulu kunezinye izinto, kodwa ukuhlala ixesha elide kunye nesibheno sobuhle sihlala sithethelela utyalo-mali.

Q10: Ndingawathenga phi amashiti entsimbi angenasipili?

I-A10: I-Mirror i-stainless steel sheets ifumaneka kubathengisi besinyithi, abavelisi, kunye nabasasazo abakhethekileyo kwiimveliso zetsimbi. Basenokunikezela ngoluhlu lweesayizi, amabakala, kunye nokugqiba ukuze zihambelane neemfuno zeprojekthi.

Ezi FAQs zibonelela ngombono obanzi wesipili samaphepha ensimbi engenasici, izicelo zabo, izibonelelo, ukugcinwa, kunye nokukhethwa ngokwezifiso.

Ixesha lokuposa: Jun-12-2024