Izinto eziluncedo:

1. Okusezantsi ubukhulu bephepha bubuhle kwaye busebenza kakuhle

2. Ukuhombisa kwandisa amandla ezinto eziphathekayo

3. Yenza umphezulu wezinto eziphathekayo ukhululeke

4. Enye iembossing inika inkangeleko ebambekayo yokugqiba.

Ibakala kunye nobukhulu:

Izinto eziphambili ziyi-201, 202, 304, 316 kunye nezinye iipleyiti zensimbi ezingenasici, kunye neenkcukacha eziqhelekileyo kunye nobukhulu: 1000 * 2000mm, 1219 * 2438mm, 1219 * 3048mm; inokunganqunywa okanye ifakwe kumqulu wonke, kunye nobukhulu be-0.3mm ~ 2.0mm.

Isebenza njani inkqubo ye-embossing:

1. UkuKhethwa kwePhepha leNsimbi elingenaStainless:Inkqubo iqala ngokukhetha ishidi lensimbi engenasici efanelekileyo. Intsimbi engatyiwayo ikhethwa ngenxa yokuqina kwayo, ukuxhathisa umhlwa, kunye nenkangeleko yobuhle ngokubanzi.

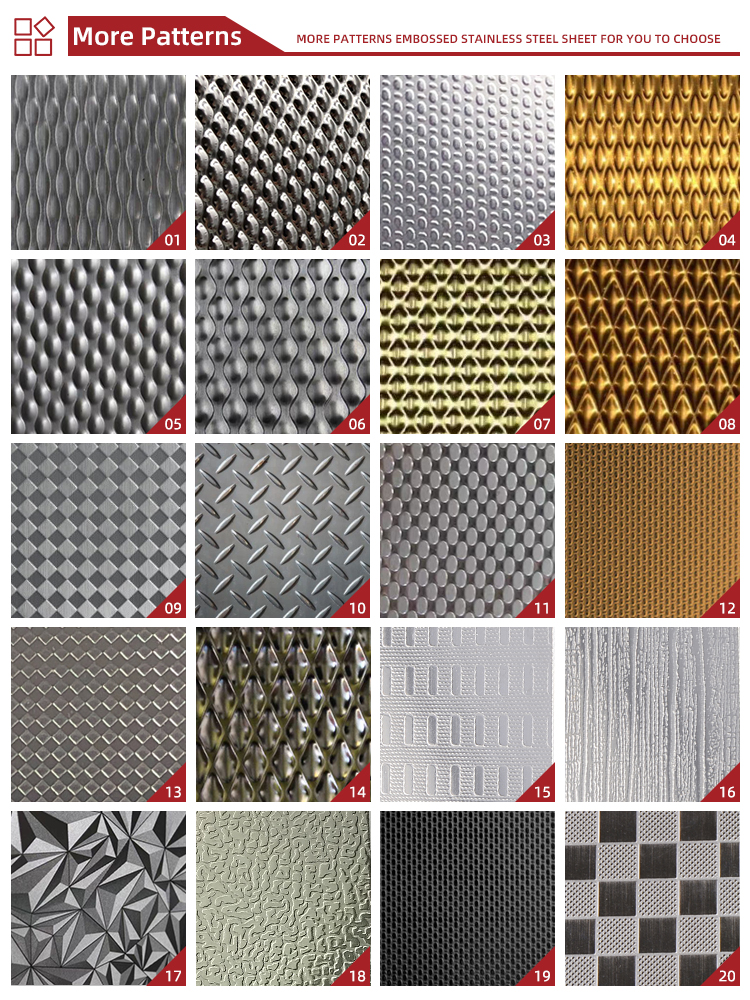

2. Ukukhethwa koyilo:Uyilo okanye iphethini ikhethwa kwinkqubo yokufaka i-embossing. Kukho iipateni ezahlukeneyo ezikhoyo, ukusuka kwiimilo zejometri ezilula ukuya kwizinto ezintsonkothileyo.

3. Ukulungiswa komphezulu: Umgangatho weshidi lensimbi engenasici licocwe ngokucokisekileyo ukuze lisuse naluphi na ukungcola, ioli, okanye ukungcola okunokuphazamisa inkqubo yokufaka i-embossing.

4. Ukuhombisa:Iphepha lensimbi elicociweyo libekwe ke phakathi kwee-roller embossing, ezifaka uxinzelelo kunye nokudala ipateni efunwayo kwindawo yephepha. I-roller embossing inomzekelo obhalwe kuwo, kwaye idlulisela iphethini kwintsimbi njengoko idlula.

5. Unyango lobushushu(Ukhetho): Kwezinye iimeko, emva kokufakwa kwe-embossing, ishidi lensimbi engenasici linokuthi liqhube inkqubo yokunyanga ukushisa ukuze lizinzise isakhiwo sesinyithi kunye nokunciphisa nayiphi na ingcinezelo eyenziwe ngexesha lokufaka i-embossing.

Ukuqukumbela

Iphepha elifakwe intsimbi engatyiwayongezicelo ezininzi ezinokubakho. Qhagamshelana neHermes Steel namhlanje ukuze ufunde ngakumbi malunga neemveliso zethu, kunye neenkonzo okanye ufumane iisampulu zasimahla. Siya kukuvuyela ukukunceda ufumane isisombululo esifanelekileyo kwiimfuno zakho. Nceda uzive ukhululekileQHAGAMSHELANA NATHI

Ixesha lokuposa: Sep-15-2023