Uhlobo lokulungisa umphezulu wensimbi engenasici

Xa intsimbi engenastainless iphuma kwizixhobo ezinkulu zentsimbi, iza kumqulu ogcweleyo kunye nomphezulu ofana nenkungu, owaziwa ngokuba licala le-2B. Kukwakho nendawo ebizwa ngokuba licala leBA. Ukukhanya kwalo mphezulu kubizwa ngokuba yi-6K. Ke imibala eyahlukeneyo, iipateni, kunye neepleyiti zentsimbi ezimile ezibunjiweyo zilungiswa kamva. Ububanzi beentsimbi zentsimbi kwiintsimbi ezinkulu zetsimbi zilinganiselwe, enye i-1219mm ububanzi, enye i-1000mm ububanzi, kwaye enye i-1500mm ububanzi. Ke ngoko, azikho iiplati zentsimbi ezihlobisayo ezinobubanzi be-1800mm kunye nobude be-1900mm kwimarike.

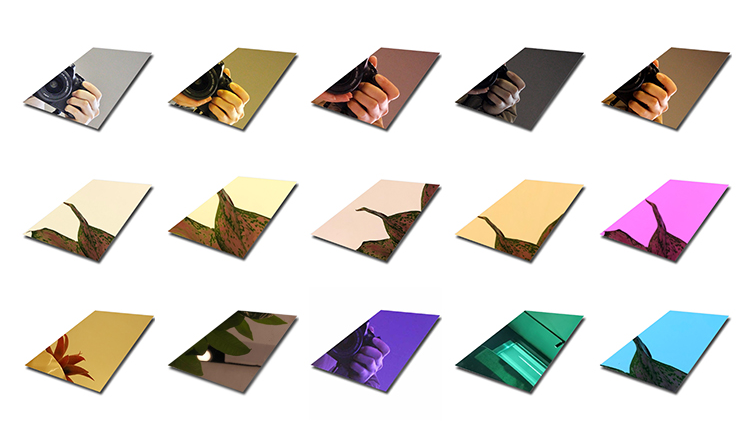

Ukuqhubekeka komphezulu:

1. Umphezulu wesipili(ekwabizwa ngokuba yi-8K): Umphezulu we-Mirror uthetha ukuba ipleyiti yensimbi engenasici igudiswa ngumatshini ukuze ibukeke njengesibuko, esikhanyayo kwaye sikhanyayo. Iikhoyili zensimbi ezingenasici nazo zinokugqitywa ngesibuko.

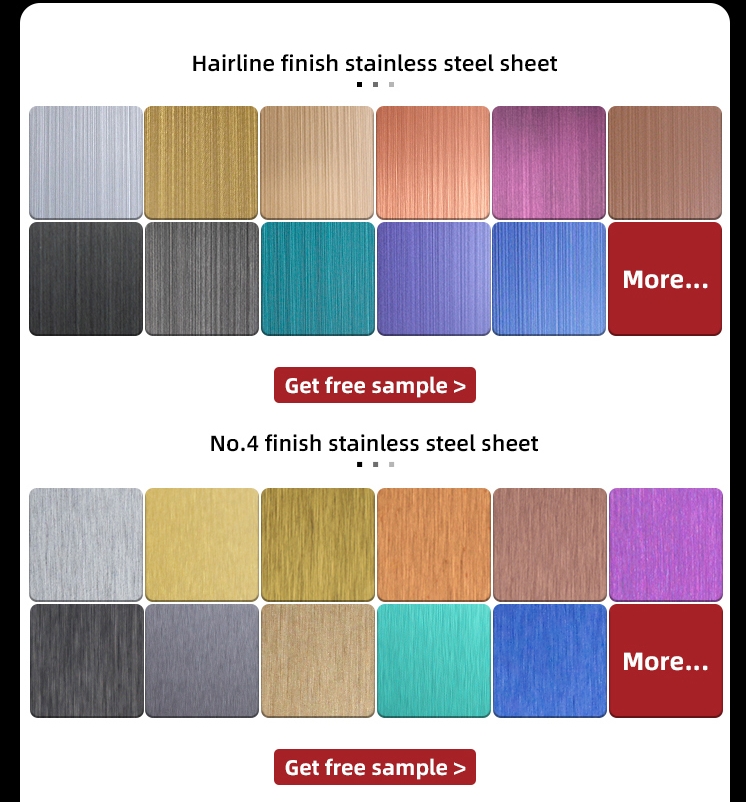

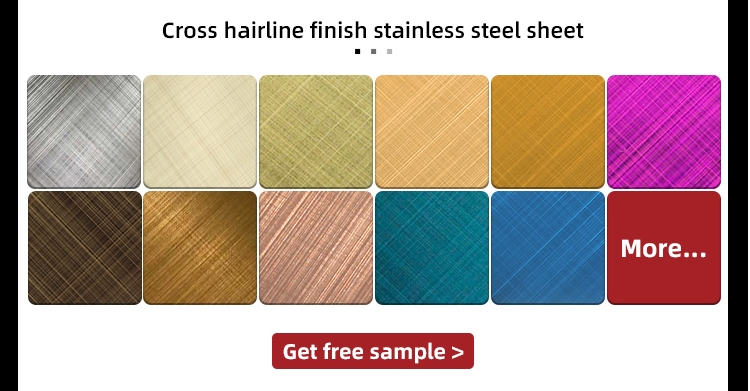

2. Ibrashi, NO.4, Isanti eqhelekileyo: I-Brushed, i-Snowflake Sand, kunye ne-Ordinary Sand nazo zibizwa ngokuba yi-frosted. Ezi ntlobo zintathu zomphezulu wentsimbi ecocekileyo zibizwa ngokuba ziyafana ngenxa yeepateni zesanti ezahlukeneyo kumphezulu. Ubume besanti yesanti ebrashiweyo yeyona ingqindilili kwaye inde kakhulu, ilandelwa yisanti eqhelekileyo, kwaye ubume besanti yesanti yekhephu yeyona incinci kwaye intle. Kakade ke, iimfuno zabo zomatshini wokulungisa nazo zahlukile. Ixabiso lelokuba ngoku kukho abavelisi abafuna ukuba ubuso benziwe ngesanti edibeneyo. Umzekelo, kuyimfuneko ukugaya isanti yekhephu kanye kwaye wenze umzobo. Iikhoyili zensimbi ezingenasici nazo zinokucutshungulwa ngolu hlobo.

Ezi zimbini zingasentla zezona zisisiseko sokuqhubekeka.

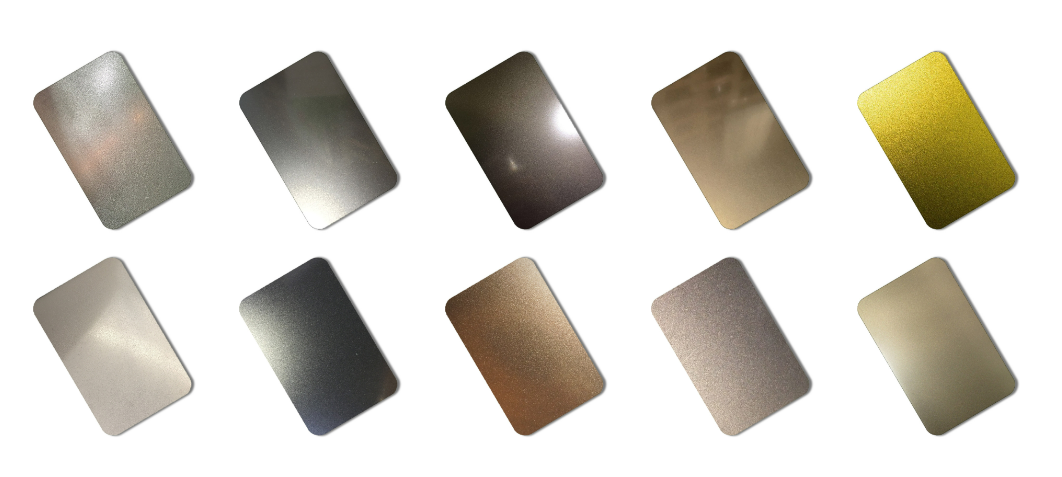

3. Ukuqhunyiswa kwesanti: Oku kuthetha ukuba umphezulu wepleyiti yensimbi engenasici ubonisa umphezulu wesanti ocolekileyo. Nangona kunjalo, i-sandblasting yentsimbi engenastainless yahlulwe ibe yi-matte sandblasting kunye ne-sandblasting eqaqambileyo. I-Matte ithetha ukuba ibhodi ifakwe isanti xa isekho kumphezulu we-2B, kunye neendlela ezikhazimlayo emva kokugulisa umphezulu wesipili. Kwithiyori, iikhoyili zensimbi ezingenasici zingasetyenziselwa olu hlobo lokucubungula, kodwa okwangoku akukho matshini onjalo wokuvelisa.

4. Ukungcangcazela: ikwabizwa ngokuba yipateni ehambelanayo. Umphezulu wale pleyiti yentsimbi ecociweyo iya kubonisa isangqa seepateni zesanti xa ijongwe kude, ngelixa iya kubonakala njengeepateni ezingaqhelekanga kunye neziphithiphithi xa zijongwa kumgama okufutshane.

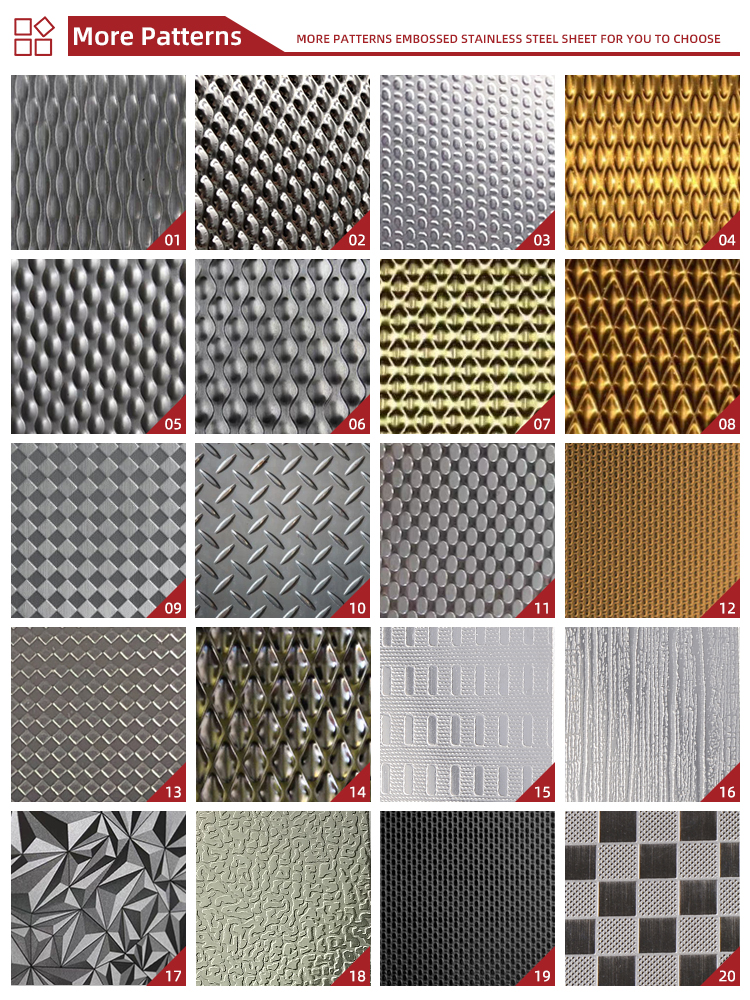

5. Ukuhombisa: Abanye abantu bayibiza ngokuba yi-embossing, eyipleyiti yensimbi engenasici esiyibona phezulu kunye neerhombusi ezincinci, iityhubhu, izikwere kunye neepatheni zepanda. Kodwa xa siqhuba, kunokwenziwa kuphela ngezinto eziqengqelekayo. Olu hlobo lokucubungula alunakwenziwa nge-4 * 8-foot plate. Kufuneka igxininiswe kwaye emva koko ibe mcaba ukuze ibe neepateni esizibonayo. Ipleyiti yensimbi engenasici.

6. Ukufakwa kwe-Titanium: Yintoni abantu abaninzi abayibiza ngokuba yintsimbi yentsimbi enemibala okwangoku eneneni ipleyiti enombala othile phezu komhlaba emva kokufakwa kwe-titanium, njengegolide yetitanium etyheli, igolide ezuke, isafire eluhlaza, njl njl. Xa ufaka umbala, iipleyiti ezintlanu ezisele zicutshungulwe zikhankanywe ngasentla zinokuba nemibala, kodwa emva kokuba ipateni yentsimbi engenasici iphuma, kufuneka iphuculwe ukuya kwi-6-8K ngomatshini we-8K. Yongeza umbala kuphela ngesiphumo esihle. Kukho enye imfuneko kwi-titanium plating. Oko kucetywayo kukwenza i-titanium emnyama, enokwenziwa ngesithando somlilo se-titanium. Nangona kunjalo, eyona ndlela isetyenziswayo ngoku kukufaka i-titanium emnyama ngamanzi. I-potion ilungiselelwe ngokomlinganiselo othile, kwaye ke ipleyiti ifakwe kwi-potion. Echibini, i-electrolysis yenza umphezulu wensimbi engenasici ubonakale umnyama. Ngokuqhelekileyo, isiphumo sokutyalwa kwamanzi i-titanium emnyama singcono kune-vacuum plating. Ngoko ke, abantu abaninzi babhekisela kumacwecwe enziwe ngerose gold njenge rose gold stainless steel, okanye titanium plates.

7. Etching: Kukusebenzisa iikhemikhali kumphezulu wensimbi engenasici ukwenza kubonakale kungalingani, okanye kunye nesicatshulwa okanye iipateni ezithile. Ngokuqhelekileyo, iipleyiti ezisetyenziselwa ukuthungwa ziye zacutshungulwa kwangaphambili. Zinokufakwa imibala kuqala kwaye zifakwe, okanye zinokubhalwa kuqala kwaye zibe nombala. Ipateni edibeneyo inokuthi ifakwe ngokwepateni okanye isicatshulwa esifunwa ngumthengi, kwaye akukho mkhondo wepatheni yangaphambili ngasemva kweplate eqoshiwe.

8. Ukususwa kwe-Titanium: Abanye abantu babiza ipleyiti emva kokususwa kwe-titanium ebizwa ngokuba yintsimbi enemibala. Njengoko igama libonisa, ukususwa kwe-titanium kukuqala ngokubeka i-titanium kwipleyiti, emva koko umbala ususwe kwindawo echongiweyo ukufezekisa ipateni ethile kunye nokumila.

9. ILaser: Le nkqubo ngoku isetyenziswa kwiinkalo ezininzi. Nangona kunjalo, umenzi othile wokucubungula uyimfihlo okwangoku.

10.Anti-iminwe: Uluhlu lweoyile lufakwe kumphezulu weplate yensimbi engenasici kwaye yomiswe ukuze kufezekiswe i-anti-fingerprint kunye ne-anti-oxidation effects.

11.Intsimbi enombala engenasici: Insimbi engenambala kwi-industry steel stainless ibhekisela: ukwenza iipatheni ebusweni bensimbi engenasici eye yafumana unyango olusisiseko. Yahlukile kwi-titanium, i-etching, kunye ne-embossing. Umzekelo unokugqitywa ngokupheleleyo ngumthengi. Ngokomzekelo, abathengi banokukhetha ukwenza "NgaseMlambo Ngexesha loMthendeleko we-Qingming" okanye umbala ongenakwenziwa nge-titanium. Umphezulu webhodi eyenziwe ngale nkqubo ibonakala njengeplastiki, kwaye umbala kunye nephethini zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.

12.Iphepha elineLaminated: Imveliso yefilimu eprintiweyo idityaniswe kumphezulu weplate yensimbi engenasici ngokuyinamathisela, enokuvelisa iipateni ezigqwesileyo kunye neepatheni.

13.Ukufakwa kobhedu: Umphezulu wensimbi engenasici ufakwe ngobhedu. Abanye abathengi bathi yonke into abayifunayo ngumbala wobhedu, ngoko ke bakhetha ubhedu olufakwe i-titanium. Kukho nabathengi abaninzi abafuna ukuba iiplate zibe neminyaka yobudala kunye ne-antiqued, efuna ubhedu olufakwe emanzini okanye ubhedu olubomvu olufakwe emanzini. Xa wenza i-plating yobhedu yamanzi, umphezulu awufuni ukuphathwa, kuba nangona uphathwa, uya kugutyungelwa yinto yobhedu. Emva kokutyalwa kobhedu, kufakwa isilika emnyama, kwaye ekugqibeleni yenziwa ngaphandle kweminwe. Xa usika uvule umphezulu wale pleyiti, into oyibonayo ayingombala wokwenyani wentsimbi engatyiwayo, kodwa ngumbala wobhedu.

14.Ipleyiti yombala edibeneyo: Idityaniswe ngesiseko sezi nkqubo.

Ixesha lokuposa: Dec-14-2023