Iipleyiti zensimbi ezingenasici zisaxhaphake kakhulu kubomi bemihla ngemihla, kwaye zikwasetyenziswa kubomi bemihla ngemihla. Iipleyiti zensimbi ezingenasici zinobukhulu obuhlukeneyo kunye neenkcukacha, kwaye zininzi ezininzi. Ngaphambi kokuba ukhethe, kusafuneka ukwazi okuthile malunga nobukhulu. Kuphela ngale ndlela sinokukwazi ukuthenga ukuba yintoni ubukhulu obufanelekileyo, ubungakanani obuqhelekileyo beplate yensimbi engenasici? Ziziphi iindlela zokusika ipleyiti yensimbi engenasici?

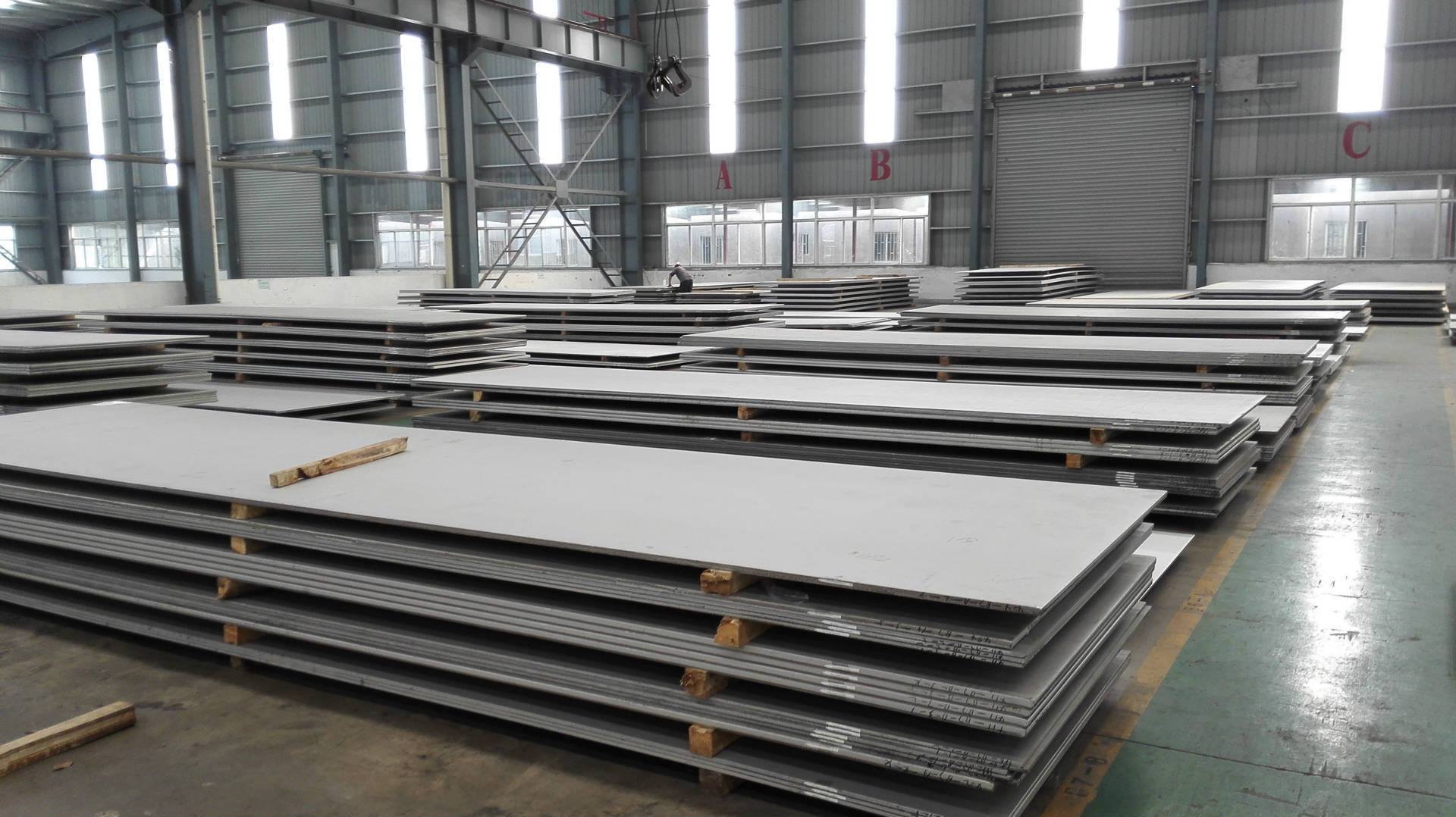

I-Stainless Steel Plate imilinganiselo yoMgangatho

1. Intsimbi yensimbi engenasici kunye nezinto eziphathekayo: 304, 316L, 321, 201, (301 tape) Isitya sensimbi yasekhaya: 430, 409, 201.

2. ipleyiti steel stainless 304 ubukhulu ipleyiti 0.12mm-65mm ipleyiti stainless steel 316L # plate ubukhulu 0.5mm-16mm.

3. Unyango lomphezulu weplate: i-8K mirror surface, i-2B i-surface egudileyo, i-sanding (umzobo, isanti ehlanjululweyo), igolide ye-titanium, i-rice grain, i-oil surface drawing, ibhodi ye-BA.

4. Plate ububanzi: 1000mm * 2000mm, 1219mm * 2438mm, 1219 * 30481219 * 3500, 1219 * 4000, 1500mm * 3000mm, 1500mm * 6000mmm.

Ziziphi iindlela zokusika ipleyiti yensimbi engenasici

1. Ukusika amadangatye: Iindleko zesi sixhobo ziphantsi. Nangona iyenye yeendlela ezimbalwa ezingabizi kakhulu zokusika iipleyiti zentsimbi ezishinyeneyo, kusekho iziphene ekusikeni ipleyiti encinci. Xa kuthelekiswa neplasma, ukusika amadangatye kunommandla omkhulu ochatshazelwe ngubushushu kunye ne-thermal deformation.

2. Ukusika i-Laser: Izixhobo zokusika i-Laser zinokusika iiplate zensimbi ezingenasici ngaphantsi kwe-30mm, kwaye emva kokufaka i-oksijini kwi-laser beam, inokunqumla i-40mm yensimbi ye-carbon steel, kodwa emva kokusika i-oksijini, ifilimu encinci ye-oxide iya kwenziwa phezu komhlaba.

3. Ukusika ucingo: Ukucutshungulwa kocingo kubizwa ngokuba yi-wire cut. Iphuhliswe ngesiseko se-EDM yokubhoboza kunye nokwenza. Ayiphuhlisi kuphela ukusetyenziswa kwe-EDM, kodwa iphinda ithathe indawo ye-perforation kunye nokubunjwa kwe-EDM kwezinye iinkalo.

4. Ukucutha i-Edge: ukucheba komphetho kusebenzisa i-blade ephezulu ehambayo kunye ne-blade esezantsi engatshintshiyo, kwaye isebenzisa i-gap efanelekileyo ye-blade ukufaka amandla okucheba kwiipleyiti zetsimbi ezinobunzima obahlukeneyo ukusika kunye nokwahlula iipleyiti ngokobungakanani obufunekayo. Owokuqala ngumatshini wokwenza umsebenzi ophambili kushishino lwesinyithi.

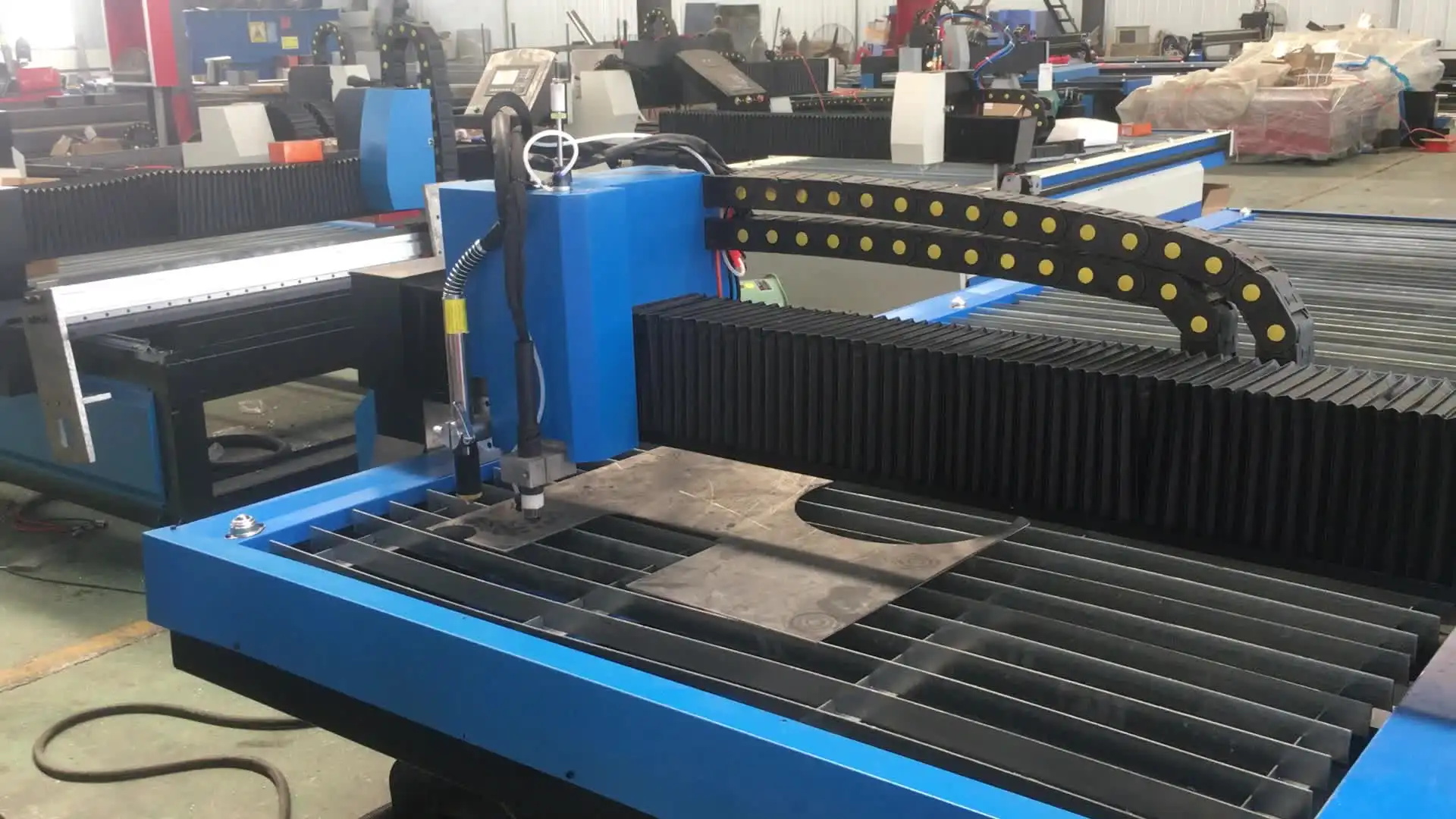

5. Umatshini wokusika i-Plasma: Le ndlela yokusika inyibilikisa isinyithi kwi-incision ye-workpiece ngokusebenzisa ukushisa okuphezulu kwe-plasma, kwaye ususe isinyithi esityhidiweyo kunye nomfutho we-plasma ye-speed-speed ukwenza i-incision.

Wonke umntu kufuneka akhethe ipleyiti yentsimbi efanelekileyo. Emva kwakho konke, ukucaciswa kweplate yensimbi kuyahluka ngeenjongo ezahlukeneyo. Asikuko ukuba ukutyeba kungcono, kodwa kuxhomekeke kwiimfuno zakho kwaye ukhethe ubukhulu obufanelekileyo ngokweemfuno zakho.

Ixesha lokuposa: May-19-2023