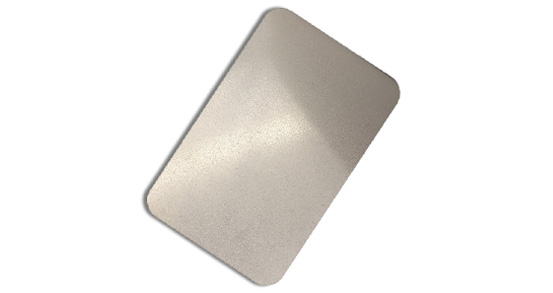

Launi bakin karfe yashi ayukan iska mai ƙarfi yana amfani da iska mai ƙarfi azaman iko, don samar da mafi daidaita allurar za ta kayan (tamar jan ƙarfe, yashi baƙin ƙarfe, yashi teku, yashi ma'adini, gwal ɗin gwal na gwal) jet mai saurin sauri zuwa buƙatar ma'amala da farfajiyar aikin, sanya bayyanar a saman fuskar bangon kayan aiki ko canjin siffar, saboda tasirin abrasive zuwa farfajiyar, yin tsafta da yanayin aiki daban-daban. workpiece iya inganta inji Properties na surface, don haka inganta gajiya juriya na workpiece, ƙara da mannewa tsakanin shafi da, mika da karko daga cikin shafi, amma kuma ga ya kwarara na Paint da kuma ado.

Idan aka kwatanta da sauran hanyoyin tsaftacewa (kamar pickling da tsaftace kayan aiki), tsarin fashewar yashi yana da halaye masu zuwa:

Yashi mai fashewa shine mafi tsafta, mafi girma, mafi sauri, mafi inganci hanyar tsaftacewa.

Na biyu, ana iya zaɓar maganin fashewar yashi ba bisa ka'ida ba tsakanin rashin ƙarfi daban-daban, kuma sauran hanyoyin ba su iya cimma hakan ba.

Manual polishing iya wasa da surface amma gudun ne ma jinkirin, sinadaran ƙarfi tsaftacewa ba conducive ga surface ga m shafi manne.

Sandblasting galibi yana da aikace-aikace masu zuwa:

(1) da workpiece shafi, plating, workpiece bonding jiyya.

Sandblasting iya cire duk datti kamar tsatsa fata a kan surface na workpiece, da kuma kafa da muhimmanci sosai asali juna a kan surface na workpiece (wato, abin da ake kira gashi surface), kuma za a iya musanya ta daban-daban barbashi size of abrasive, don cimma daban-daban mataki na roughness, ƙwarai inganta aikin da shafi, plating abu mannewa.

Ko don sanya haɗin haɗin haɗin gwiwa ya fi ƙarfi, mafi inganci.

(2) tsaftacewa da goge tarkacen simintin simintin gyare-gyare da ɓangarorin ƙirƙira da kayan aikin bayan maganin zafi.

Sandblasting zai iya tsaftace duk wani datti a saman simintin gyare-gyare da ƙirƙira sassa, bayan maganin zafi (kamar oxide fata, babu datti da sauran ragowar), da goge saman kayan aikin don haɓaka santsi na aikin, kunna aikin ƙawata aikin.

Sandblasting tsaftacewa na iya sa workpiece nuna uniform karfe launi, sa workpiece bayyanar mafi kyau, don ƙawata rawar da ado.

(3) Burr tsaftacewa da kuma surface kawata sassa machining.

Yashi mai fashewa zai iya tsaftace ƙananan burr a saman kayan aikin, kuma ya sa saman aikin ya fi dacewa, cire cutar da burr, inganta matakin aikin.

Kuma sandblasting iya zama a cikin workpiece surface junction buga wani karamin zagaye kusurwa, sabõda haka, workpiece bayyana mafi kyau, mafi daidai.

(4) inganta inji Properties na sassa.

Bayan fashewar yashi, sassan injiniyoyi na iya samar da uniform da dabara mai ma'ana da madaidaicin shimfidar wuri (tsari na asali) akan saman sassan da ake buƙata, ta yadda za'a iya adana tabon lubrication, don haɓaka yanayin lubrication, rage hayaniya da haɓaka rayuwar sabis na injin.

(5) kayan ado mai haske.

1. Yaren mutanen Poland daban-daban workpiece saman don sa su mafi kyau.

2, sanya workpiece don saduwa da buƙatun santsi da maras kyau, wato, don cimma wani ƙaƙƙarfan yanayi.

Don wasu dalilai na musamman na aikin aikin, yashi na iya zama na zaɓi don cimma haske daban-daban ko ƙaramin haske.

Ƙarin bayanin macro na bakin karfe mai wadata don Allah ziyarci: https://www.hermessteel.net.

Lokacin aikawa: Oktoba-29-2019