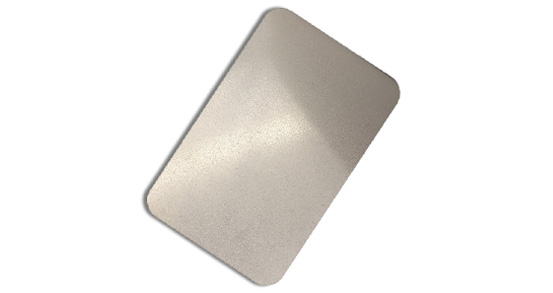

Ho phatloha ha lehlabathe le nang le 'mala o sa hloekang ho sebelisa moea o hatelitsoeng e le matla, e le hore ho ka etsoa ente ea ho lokisa ka ho fetisisa e tla ba lintho tse bonahalang (ore ea koporo, lehlabathe la tšepe, lehlabathe la leoatle, lehlabathe la quartz, khauta ea tšepe ea khauta) jete ea lebelo le phahameng ho ea ho tlhokahalo ea ho sebetsana le sebaka sa mosebetsi, ho etsa ponahalo holim'a sefahleho sa workpiece kapa sebopeho sa sebopeho, ka lebaka la phello e hlabang le phello e hloekisitsoeng holim'a sehatsetsi sa ho seha. roughness, etsa workpiece ka ntlafatsa thepa ea mechine ea holim'a metsi, kahoo ntlafatsa mokhathala ho hanyetsa ea workpiece, e ile ea eketseha ho khomarela lona pakeng tsa barbotage le, atolosa durability ya barbotage, empa hape le ho phalla ha pente le mokhabiso.

Ha ho bapisoa le lits'ebetso tse ling tsa ho hloekisa (joalo ka ho khetha le ho hloekisa lisebelisoa), ts'ebetso ea sandblasting e na le litšobotsi tse latelang:

Ho phatloha ha lehlabathe ke mokhoa o hlakileng ka ho fetisisa, o akaretsang, o potlakileng ka ho fetisisa, o sebetsang ka ho fetisisa oa ho hloekisa.

Ntlha ea bobeli, phekolo ea sandblasting e ka khethoa ka mokhoa o ikemetseng pakeng tsa mahlahahlaha a fapaneng, 'me mekhoa e meng ha e khone ho finyella sena.

Ho hloekisoa ka letsoho ho ka bapala bokaholimo empa lebelo le lieha haholo, ho hloekisa lik'hemik'hale ha ho khonehe ho ea holimo bakeng sa ho khomarela boreleli.

Sandblasting haholo-holo e na le lisebelisoa tse latelang:

(1) workpiece barbotage, plating, workpiece bonding kalafo.

Sandblasting ka tlosa litšila tsohle tse kang mafome letlalo holim'a workpiece, 'me ho theha ea bohlokoa haholo tsa motheo paterone holim'a workpiece (ke hore, ho thoeng ka holim'a moriri), 'me e ka fapanyetsana ka boholo phatsa ea abrasive, ho finyella tekanyo e fapaneng ya roughness, haholo ntlafatsa mosebetsi le barbotage, plating lintho tse bonahalang khomarela.

Kapa ho etsa hore sekotoana sa bonding se tlamahane ka thata haholoanyane, boleng bo betere.

(2) ho hloekisa le ho bentsa bokaholimo bo mahoashe ba likarolo tsa samente le tse ferekaneng le sesebelisoa ka mor'a kalafo ea mocheso.

Sandblasting ka hloekisa litšila tsohle holim'a ho lahla le forging likarolo, ka mor'a kalafo mocheso (tse kang oxide letlalo, ha ho na litšila le masala a mang), le bentsa holim'a workpiece ho ntlafatsa boreleli ba workpiece, phetha karolo ea ho khabisa workpiece.

Ho hloekisa lehlabathe ho ka etsa hore sesebedisoa se bonts'e 'mala oa tšepe o ts'oanang, ho etsa hore mosebetsi oa matsoho o be motle le ho feta, ho khabisa karolo ea mokhabiso.

(3) ho hloekisa li-burr le ho khabisa bokaholimo ba likarolo tsa mochini.

Ho phatloha ha lehlabathe ho ka hloekisa burr e nyenyane holim'a sesebedisoa sa mosebetsi, 'me ho etsa hore bokaholimo ba mosebetsi o be bonolo haholoanyane, ho tlosa kotsi ea burr, ho ntlafatsa boemo ba mosebetsi.

Le sandblasting ka ba ka workpiece holim'a mateano otla e nyenyane pota hukung, e le hore workpiece e bonahala e le ntle le ho feta, nepahetseng haholoanyane.

(4) ntlafatsa thepa ea mechine ea likarolo.

Kamora ho phatloha ha lehlabathe, likarolo tsa mochini li ka hlahisa li-concave tse ts'oanang le tse poteletseng le bokaholimo ba li-convex (schema ea motheo) holim'a likarolo tse hlokahalang, e le hore matheba a lubrication a ka bolokoa, e le ho ntlafatsa maemo a lubrication, ho fokotsa lerata le ho ntlafatsa bophelo ba ts'ebeletso ea mochini.

(5) mokhabiso o bobebe.

1. Likarolo tse fapaneng tsa li-workpiece tsa Poland ho li etsa hore li be ntle le ho feta.

2, etsa hore workpiece e finyelle litlhoko tsa boreleli le tse sa bonts'ang maikutlo, ke hore, ho finyella boima bo itseng ba holim'a metsi.

Bakeng sa merero e khethehileng ea workpiece, sandblasting e ka ba boikhethelo ho finyella khanya e fapaneng kapa e nyenyane.

Lintlha tse ling tse ngata tse atlehileng tsa tšepe e sa hloekang ka kopo etela: https://www.hermessteel.net.

Nako ea poso: Oct-29-2019