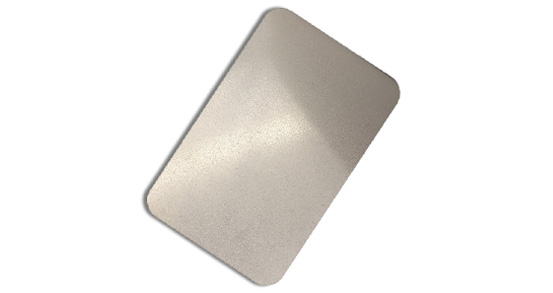

Acha igwe anaghị agba nchara ájá gbawara agbawa na-eji abịakọrọ ikuku dị ka ike, iji na-etolite kasị gbanwee injection ga ihe (ọla kọpa ore, ígwè ájá, oké osimiri ájá, quartz ájá, ọla edo grit) elu-ọsọ jet ka mkpa obibi workpiece elu, na-eme ka ọdịdị n'elu nke workpiece elu ọdịdị ma ọ bụ ọdịdị mgbanwe, n'ihi abrasive mmetụta n'elu na-eme ka ihe dị ọcha na-arụ ọrụ dị iche iche, na-eme ka ihe dị ọcha na-arụ ọrụ dị iche iche. workpiece nwere ike melite n'ibu Njirimara nke elu, si otú melite ike ọgwụgwụ na-eguzogide nke workpiece, mụbara ya adhesion n'etiti mkpuchi na, ịgbatị anwụ ngwa nke mkpuchi, kamakwa eruba nke agba na mma.

E jiri ya tụnyere usoro ihicha ndị ọzọ (dị ka pickling na ihicha ngwá ọrụ), usoro ịkụcha ájá nwere àgwà ndị a:

Mgbawa aja bụ nke kachasị nke ọma, nke kachasị n'ozuzu, nke kachasị ngwa ngwa, nke kachasị dị irè.

Nke abuo, enwere ike ịhọrọ ọgwụgwọ nke ájá ájá n'ụzọ aka ike n'etiti adịghị ike dị iche iche, na usoro ndị ọzọ enweghị ike ime nke a.

Iji aka polishing nwere ike igwu elu ma ọsọ na-adị ngwa ngwa, kemịkalụ ihe mgbaze ihicha adịghị mma n'elu maka ire ụtọ mkpuchi adhesion.

Sandblasting na-enwekarị ngwa ndị a:

(1) na workpiece mkpuchi, plating, workpiece bonding ọgwụgwọ.

Sandblasting nwere ike wepụ niile unyi dị ka nchara akpụkpọ n'elu nke workpiece, na-eguzobe a dị nnọọ mkpa isi ụkpụrụ n'elu nke workpiece (ya bụ, a na-akpọ ntutu elu), na ike ga-gbanwere site dị iche iche urughuru size nke abrasive, iji nweta dị iche iche n'ókè nke roughness, ukwuu mma ọrụ na mkpuchi, plating ihe nrapado.

Ma ọ bụ iji mee ka mpempe akwụkwọ njikọ ahụ sie ike, ka mma.

(2) ihicha na polishing nke siri ike elu nke nkedo na esorowo akụkụ na workpiece mgbe okpomọkụ ọgwụgwọ.

Sandblasting nwere ike ihicha ihe niile unyi n'elu nke nkedo na akpụ akụkụ, mgbe okpomọkụ ọgwụgwọ (dị ka oxide akpụkpọ, dịghị unyi na ndị ọzọ residues), na polishing elu nke workpiece ka mma ire ụtọ nke workpiece, na-arụ ọrụ nke ịchọ mma na workpiece.

Sandblasting ihicha nwere ike ime ka workpiece egosi edo metal agba, mee ka workpiece anya ọzọ mara mma, na-mma ọrụ nke ịchọ mma.

(3) Burr ihicha na elu mma nke machining akụkụ.

Mgbawa ájá nwere ike ihicha obere burr dị n'elu nke ọrụ ahụ, ma mee ka elu nke ọrụ ahụ dịkwuo elu, wepụ ihe ọjọọ nke burr, melite ọkwa nke workpiece.

Na sandblasting nwere ike ịbụ na workpiece elu junction see a obere gburugburu akuku, nke mere na workpiece pụtara mara mma, ọzọ kpọmkwem.

(4) melite n'ibu Njirimara nke akụkụ.

Mgbe ájá ájá gasịrị, akụkụ ígwè ọrụ nwere ike ịmepụta otu na nke dị nro concave na convex elu (isi atụmatụ) n'elu akụkụ ndị a chọrọ, nke mere na a na-echekwa ntụpọ lubrication, iji mee ka ọnọdụ mmanu mma dịkwuo mma, belata mkpọtụ ma melite ndụ ọrụ nke igwe.

(5) ihe ịchọ mma ọkụ.

1. Polish dị iche iche workpiece na-ebupụta na-eme ka ha mara mma.

2, na-eme ka workpiece na-ezute chọrọ nke ire ụtọ na-adịghị egosipụta, ya bụ, iji nweta a ụfọdụ elu roughness.

Maka ụfọdụ ebumnuche pụrụ iche nke workpiece, sandblasting nwere ike ịbụ nhọrọ iji nweta ìhè dị iche iche na-egosipụta ma ọ bụ sub-light.

Ozi igwe anaghị agba nchara macro bara ọgaranya biko gaa na: https://www.hermessteel.net.

Oge nzipu: Ọktoba 29-2019