Nrog rau txoj kev loj hlob ntawm lub sij hawm, ntau thiab ntau tus neeg xaiv cov xim stainless hlau los ua cov khoom siv kho kom zoo nkauj, thiab cov qauv no tau dhau los ua ntau thiab pom tseeb.Yog li cas stainless hlau xim phaj plated?

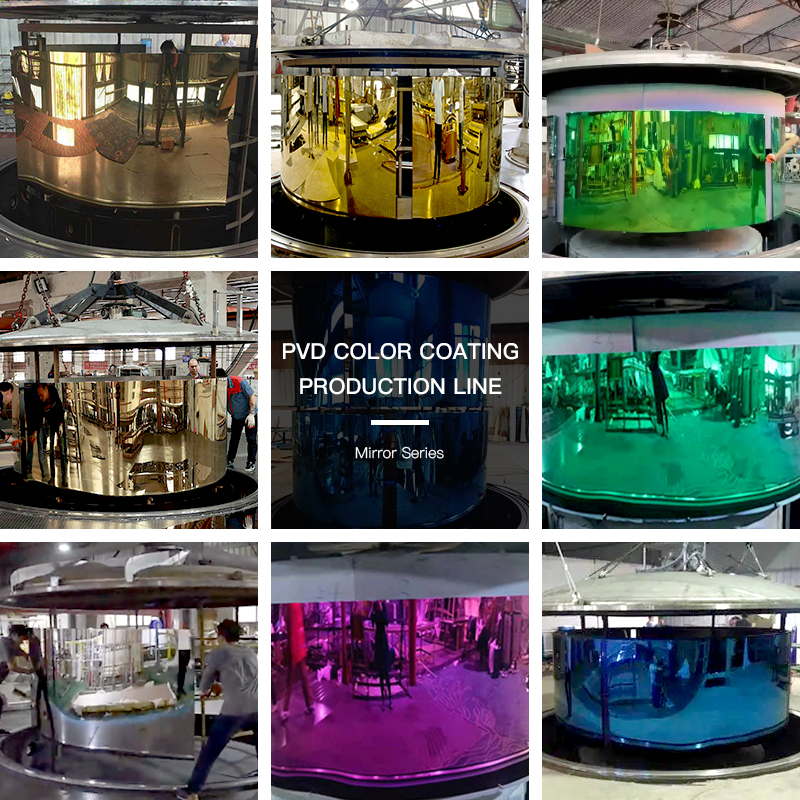

Peb feem ntau siv xim plating txoj kev rau stainless hlau xim daim hlau

1. Nqus plating

Txheej Txheem: Xim plating yog ua nyob rau hauv lub tshuab nqus tsev ib puag ncig ntawm qhov kub thiab txias.

Nta: Ib puag ncig tus phooj ywg, zoo hlau zoo nkauj, ntev ntev thiab ci xim

Cov xim plating: dub titanium (zoo tib yam dub), titanium kub, kub kub, champagne kub, sawv kub, daj bronze, burgundy, xim av, xim av, sapphire xiav, emerald ntsuab, 7 xim, thiab lwm yam.

Stainless hlau xim phaj nqus platingyog ib txoj hauv kev txuas cov yeeb yaj kiab los yog txheej rau saum npoo ntawm stainless hlau kom hloov nws cov xim thiab cov tsos. Cov txheej txheem no feem ntau yog muab lub phaj stainless hlau tso rau hauv lub tshuab nqus tsev thiab tom qab ntawd tso cov yeeb yaj kiab lossis txheej txheej rau saum npoo hauv qab lub tshuab nqus tsev. Nov yog cov kauj ruam dav dav:

1. Npaj lub stainless hlau nto: Ua ntej, stainless hlau nto yuav tsum tau npaj los xyuas kom meej tias qhov chaw huv si thiab tsis muaj av, roj, los yog lwm yam impurities. Qhov no tuaj yeem ua tiav los ntawm kev siv tshuaj ntxuav lossis kho tshuab.

2.Nqus chamber teeb tsa: Stainless hlau phaj yog muab tso rau hauv lub tshuab nqus tsev vacuum chamber, uas yog ib qho chaw kaw uas muaj peev xwm tswj tau lub siab thiab cua. Feem ntau muaj ib lub rooj sib hloov nyob rau hauv qab ntawm lub tshuab nqus tsev chamber uas tig lub stainless hlau phaj kom ntseeg tau tias tsis sib xws deposition.

3.Cua sov: Nyob rau hauv lub tshuab nqus tsev chamber, stainless hlau daim hlau tej zaum yuav raug kho kom sov los txhim kho nto adhesion rau films los yog coatings. Cov cua sov kuj pab nrog kev tso dej tsis sib xws ntawm zaj duab xis.

4. Nyias zaj duab xis deposition: Nyob rau hauv lub tshuab nqus tsev, cov ntaub ntawv nyias nyias (feem ntau yog hlau lossis lwm yam sib txuas) yog evaporated lossis txau rau ntawm qhov chaw stainless hlau. Qhov no tuaj yeem ua tiav los ntawm txoj hauv kev xws li electron beam evaporation, magnetron sputtering, tshuaj vapor deposition, thiab lwm yam. Thaum cov yeeb yaj kiab tso, lawv tsim cov txheej txheej ntawm cov hlau tsis huv.

5. Cooling thiab solidification: Tom qab cov yeeb yaj kiab tso, cov phaj hlau stainless yuav tsum tau ua kom txias thiab khov rau hauv lub tshuab nqus tsev kom paub meej tias cov txheej txheem ruaj khov rau saum npoo. Cov txheej txheem no tuaj yeem ua tiav hauv lub tshuab nqus tsev.

6. Kev tswj kom zoo: Tom qab ua tiav kev tso tawm thiab kho, kev tswj xyuas zoo ntawm cov hlau tsis muaj xim hlau yuav tsum tau ua kom ntseeg tau tias cov xim thiab cov tsos ua tau raws li qhov yuav tsum tau ua.

7. Ntim thiab xa khoom: Thaum nws dhau qhov kev tswj xyuas zoo, cov xim hlau electroplated stainless hlau tuaj yeem ntim thiab xa mus rau cov neeg siv khoom lossis cov chaw tsim khoom rau lawv qhov kawg siv.

Lub tshuab nqus tsev electroplating ntawm stainless hlau xim daim hlau tuaj yeem ua tiav ntau yam xim thiab cov teebmeem, thiab zoo nkauj heev thiab ruaj khov. Txoj kev no feem ntau yog siv rau hauv thaj chaw xws li kho kom zoo nkauj high-end, hniav nyiaj hniav kub thiab saib kev tsim khoom los hloov cov tsos ntawm cov hlau tsis muaj steel.

2. Dej plating

Txheej Txheem: Xim plating hauv cov kev daws teeb meem tshwj xeeb

Nta: Tsis yog ib puag ncig tus phooj ywg txaus, txwv plating xim

Cov xim plating: dub titanium (blackened), bronze, liab bronze, thiab lwm yam.

Cov kauj ruam dav dav rau dej plating ntawm stainless hlau xim daim hlau:

Kev kho saum npoo: Ua ntej, qhov saum npoo ntawm stainless hlau phaj yuav tsum tau muab ntxuav thiab kho kom ntseeg tau tias tsis muaj roj, av lossis lwm yam impurities. Cov kauj ruam no yog qhov tseem ceeb vim nws ua kom muaj kev sib haum xeeb thiab adhesion ntawm cov txheej txheem dyeing tom ntej.

Kev kho mob ua ntej: Ua ntej dej plating, stainless hlau nto feem ntau xav tau qee qhov tshwj xeeb pretreatment los ua kom cov adhesion ntawm cov xim. Qhov no yuav suav nrog kev siv cov txheej txheem ua ntej kev kho dej rau saum npoo kom nws yooj yim rau nqus cov xim.

Dej Plating: Cov kauj ruam tseem ceeb ntawm cov dej plating yog siv cov kua dyeing (feem ntau yog dej) uas muaj cov xim thiab cov tshuaj rau cov hlau tsis huv. Cov kua dyeing no tuaj yeem muaj cov xim tshwj xeeb, tus neeg sawv cev oxidizing, thiab tejzaum nws yog diluent. Thaum cov kua dyeing tuaj rau hauv kev sib cuag nrog cov hlau tsis huv, cov tshuaj tiv thaiv tshwm sim, ua rau cov xim ua raws li qhov chaw.

Curing thiab ziab: Dyed stainless hlau panels feem ntau yuav tsum tau kho thiab qhuav nyob rau hauv cov xwm txheej tsim nyog los xyuas kom meej tias cov xim ruaj khov thiab ruaj khov. Qhov no yuav suav nrog cov kauj ruam xws li cua sov lossis cua kom qhuav.

Kev tswj kom zoo: Tom qab ua tiav ntawm dyeing thiab ziab, kev tswj kom zoo ntawm cov hlau tsis muaj xim hlau yuav tsum tau ua. Qhov no suav nrog kev tshuaj xyuas cov xim sib xws, adhesion, durability thiab qhov ua tau tsis zoo.

Ntim thiab xa khoom: Thaum nws dhau qhov kev tswj xyuas zoo, cov xim tsis muaj xim hlau xim xim tuaj yeem ntim thiab xa mus rau cov neeg siv khoom lossis cov chaw tsim khoom rau lawv qhov kawg siv.

3. Nano xim roj

Txheej Txheem: Qhov saum npoo yog xim nrog cov roj nano-xim, zoo ib yam li cov tshuaj txau

Nta: 1) Yuav luag txhua xim tuaj yeem ua electroplated

2) Colorant tuaj yeem ua los ntawm tooj liab tiag

3) Tsis muaj kev tiv thaiv ntiv tes tom qab cov roj xim tuaj nrog nws

4) Cov hlau zoo nkauj yog me ntsis zuj zus

5) Nto kev ntxhib los mos yog them rau ib qho twg

Pa plating xim: Yuav luag txhua xim tuaj yeem plated

Stainless hlau xim phaj nano xim rojyog xim txheej npaj siv nanotechnology, uas feem ntau yog siv rau saum npoo ntawm stainless hlau kom ua tiav cov xim zoo nkauj. Txoj kev no siv cov kev cuam tshuam thiab cuam tshuam ntawm nanoparticles ntawm lub teeb los tsim ntau yam xim thiab cov teebmeem. Nov yog cov kauj ruam kev npaj dav dav:

1. Kev kho saum npoo: Lub stainless hlau nto ua ntej yuav tsum tau ntxuav thiab npaj kom huv si thiab tsis muaj roj, av los yog lwm yam impurities. Qhov no yog ib kauj ruam tseem ceeb los xyuas kom meej txheej adhesion.

2. primer txheej: Ua ntej nano xim roj txheej, feem ntau nws yog tsim nyog los thov ib txheej ntawm primer los yog primer rau ntawm stainless hlau nto los txhim kho cov adhesion ntawm cov xim txheej thiab xyuas kom meej uniformity.

3. Nano xim roj txheej: Nano xim roj txheej yog txheej tshwj xeeb uas muaj nanoparticles. Cov khoom no yuav tsim kev cuam tshuam thiab cuam tshuam los ntawm lub teeb irradiation, yog li tsim cov xim sib txawv. Qhov loj thiab kev npaj ntawm cov khoom no tuaj yeem hloov kho kom ua tiav cov xim uas xav tau.

4.Curing thiab ziab: Tom qab siv cov nano xim roj txheej, lub phaj stainless hlau feem ntau yuav tsum tau kho thiab ziab hauv qhov tsim nyog kom ntseeg tau tias cov xim txheej yog ruaj khov rau saum npoo.

5. Kev tswj kom zoo: Tom qab ua tiav ntawm txheej thiab ziab, kev tswj xyuas zoo ntawm cov hlau tsis muaj xim hlau yuav tsum tau ua kom cov xim sib xws, adhesion thiab durability.

6. Ntim thiab xa khoom: Thaum nws dhau qhov kev tswj xyuas zoo, cov xim hlau tsis muaj xim hlau tuaj yeem ntim thiab xa mus rau cov neeg siv khoom lossis cov chaw tsim khoom rau lawv qhov kawg siv.

Nano xim roj thev naus laus zis tso cai rau cov xim zoo nkauj yam tsis tas siv cov xim ib txwm siv thiab yog li ntawd nrov heev hauv kev kho kom zoo nkauj, tsim thiab cov khoom siv high-end. Txoj kev no feem ntau siv rau hauv thaj chaw xws li cov hniav nyiaj hniav kub, watches, architectural kho kom zoo nkauj, thiab cov khoom siv hluav taws xob high-end.

Xaus

Stainless hlau xim daim hlau nrog ntau yam kev siv. Hu rau Hermes Steel hnub no kom paub ntau ntxiv txog peb cov khoom, thiab cov kev pabcuam lossis tau txais cov qauv dawb. Peb yuav zoo siab los pab koj nrhiav cov kev daws teeb meem zoo tshaj plaws rau koj cov kev xav tau. Thov koj txhob xav li casTiv tauj peb

Post lub sij hawm: Sep-14-2023