Nekukura kwemazuva, vanhu vakawanda vari kusarudza simbi isina mavara ane mavara sechinhu chekushongedza, uye maitiro aya ari kuramba achiwedzera kuoneka. Saka sei simbi isina tsvina yemavara inoputirwa?

Nzira nhatu dzinowanzo shandiswa mavara ekuisa mahwendefa esimbi asina ruvara

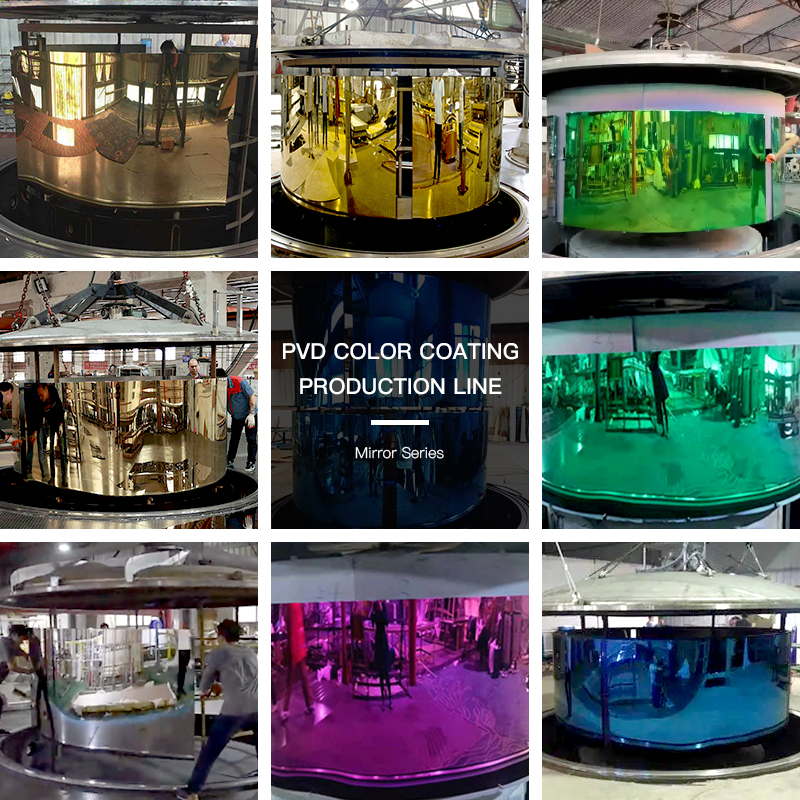

1. Vacuum plating

Maitiro: Kuiswa kwemavara kunoitwa munzvimbo yevacuum pane imwe tembiricha uye nguva.

Zvimiro: Yakanaka nharaunda, yakanaka simbi kuumbwa, inogara kwenguva refu uye yakajeka ruvara

Yakajairika plating mavara: dema titanium (yakajairika nhema), titanium goridhe, hombe goridhe, champagne goridhe, rose goridhe, yero bhuronzi, burgundy, brown, brown, safiro bhuruu, emerald girini, 7 mavara, nezvimwe.

Stainless simbi ruvara ndiro vacuum platinginzira yekubatanidza firimu kana kupfekedza pamusoro pesimbi isina tsvina kuti ichinje ruvara uye chimiro chayo. Kuita uku kunowanzo sanganisira kuisa ndiro yesimbi isina tsvina mukamuri yekutsvaira uye wozoisa firimu kana kupfekwa pamusoro pevacuum mamiriro. Heano maitiro akajairika:

1. Gadzirira nzvimbo yesimbi isina tsvina: Chekutanga, simbi isina tsvina inoda kugadzirirwa kuti ive nechokwadi chekuti nzvimbo yacho yakachena uye haina tsvina, girisi, kana kumwe kusvibiswa. Izvi zvinogona kuitwa kuburikidza nekuchenesa makemikari kana mechanical kurapwa.

2.Vacuum chamber setting: Iyo ndiro yesimbi isina tsvina inoiswa muimba yevacuum, iyo inzvimbo yakavharwa inogona kudzora kumanikidzwa kwemukati uye mhepo. Kazhinji pane tafura inotenderera pazasi pekamuri yekutsvaira inotenderedza ndiro yesimbi isina tsvina kuti ive nechokwadi chekuisa yunifomu.

3.Kupisa: Mukamuri yevacuum, mahwendefa esimbi asina tsvina anogona kupiswa kuti avandudze kunamira kwepamusoro kumafirimu kana machira. Kupisa kunobatsirawo nekuisa yunifomu yefirimu.

4. Deposition yefirimu yakaonda: Mumamiriro ezvinhu evacuum, iyo inodiwa yakaonda firimu zvinhu (kazhinji simbi kana mamwe makomisheni) inoputika kana kupfapfaidzwa pamusoro pesimbi isina tsvina. Izvi zvinogona kuwanikwa nenzira dzakadai seyerekitironi danda evaporation, magnetron sputtering, kemikari mhute deposition, etc. Kana mafirimu aiswa, anoumba yunifomu coating pamusoro Stainless simbi pamusoro.

5. Kutonhodza uye kusimba: Mushure mokunge firimu yaiswa, ndiro yesimbi isina tsvina inoda kutonhodzwa uye kusimbiswa mukamuri yevacuum kuti ive nechokwadi chokuti chifukidzo chakanyatsobatanidzwa pamusoro. Iyi nzira inogona kuitwa mukati mevacuum chamber.

6. Kudzora kwehutano: Mushure mekupedzwa kwekuisa uye kurapa, kutonga kwemhando yesimbi isina mavara mahwendefa anodiwa kuve nechokwadi chekuti ruvara uye chitarisiko zvinosangana nezvinodiwa.

7. Packaging uye Delivery: Kana yangopfuura kudzora kwemhando, iyo electroplated Stainless simbi mavara mahwendefa anogona kuiswa mukati uye kuendeswa kune mutengi kana mugadziri kuti ashandise kwekupedzisira.

Vacuum electroplating yesimbi isina tsvina mavara mahwendefa anogona kuwana akasiyana mavara nemhedzisiro, uye inoshongedza zvakanyanya uye yakasimba. Iyi nzira inowanzoshandiswa munzvimbo dzakadai sekushongedza kwepamusoro-soro, zvishongo uye kutarisa kugadzira kuchinja kutaridzika kwesimbi isina tsvina.

2. Kuisa mvura

Maitiro: Ruvara plating mune chaiyo mhinduro

Zvimiro: Hazvina hushamwari zvakaringana, mashoma eplating mavara

Yakajairika plating mavara: dema titanium (yakasviba), bhuronzi, tsvuku bhuronzi, nezvimwe.

Matanho akajairwa ekuiswa kwemvura kwesimbi isina mavara mahwendefa:

Kurapa kwepamusoro: Kutanga, pamusoro peplate yesimbi isina tsvina inoda kucheneswa uye kurapwa kuti ive nechokwadi chekuti hapana girisi, tsvina kana zvimwe zvakasvibiswa. Iyi nhanho yakakosha sezvo ichivimbisa kufanana uye kunamatira kweinotevera maitiro ekudhaya.

Pretreatment: Pamberi pemvura yekuputira, nzvimbo yesimbi isina tsvina inowanzoda imwe yakakosha pretreatment kuti iwedzere kunamatira kwepigment. Izvi zvinogona kusanganisira kuisa runyoro rwemvura isati yarapwa kumusoro kuti zvive nyore kutora pigment.

Mvura Plating: Nhanho huru yekuputira mvura inosanganisira kuisa mvura yekudhaya (inowanzo mvura-yakavakirwa) ine pigments uye makemikari panzvimbo yesimbi isina tsvina. Mvura inodhayi iyi inogona kunge iine dhayi yeruvara yakati, oxidizing agent, uye pamwe ine diluent. Kana mvura yekudhaya ikasangana nesimbi isina tsvina, kemikari inoitika, ichiita kuti ruvara runamatire pamusoro.

Kurapa nekuomesa: Dyed Stainless steel panels kazhinji inoda kurapwa uye kuomeswa pasi pemamiriro akakodzera kuti ave nechokwadi chokuti ruvara rwakasimba uye rwakasimba. Izvi zvinogona kusanganisira matanho akadai sekudziya kana kuomeswa nemhepo.

Kudzora kwehutano: Mushure mekupedzwa kwekudhaya nekuomeswa, kutonga kwemhando yesimbi isina tsvina mahwendefa anodiwa. Izvi zvinosanganisira kutarisa kufanana kwemavara, kunamatira, kusimba uye hurema hunogona kuitika.

Packaging uye Delivery: Kana ichinge yapfuura kudzora kwemhando, iyo yakadhayiwa Stainless simbi mavara mahwendefa anogona kuiswa mukati uye kuendeswa kune mutengi kana mugadziri kuti apedze kushandiswa.

3. Nano ruvara rwemafuta

Maitiro: Nzvimbo yacho ine ruvara ne nano-ruvara oiri, yakafanana nekupfapfaidza pamusoro

Zvimiro: 1) Anenge chero ruvara runogona kuve electroplated

2) Colorant inogona kugadzirwa kubva mhangura chaiyo

3) Iko hakuna kuchengetedzwa kwemunwe mushure mekunge mafuta eruvara auya nawo

4) Iyo simbi yesimbi yakashata zvishoma

5) Surface texture yakavharwa kune imwe nhanho

Yakajairika plating mavara: Inenge chero ruvara runogona kuputira

Stainless simbi color plate nano color oilchishongo cheruvara chakagadzirwa uchishandisa nanotechnology, iyo inowanzoiswa pamusoro pesimbi isina tsvina kuti iwane kutaridzika kwemavara. Iyi nzira inoshandisa kupararira uye kukanganisa mhedzisiro ye nanoparticles pachiedza kuburitsa akasiyana mavara nemhedzisiro. Heano maitiro akajairwa ekugadzirira:

1. Kurapa kwepamusoro: Iyo simbi isina tsvina yekutanga inoda kucheneswa uye kugadzirirwa kuti ive nechokwadi chekuti nzvimbo yacho yakachena uye haina girizi, tsvina kana kumwe kusvibiswa. Iri inhanho yakakosha yekuve nechokwadi chekunamatira kunamatira.

2. Primer coating: Pamberi penano color coating, zvinowanzodikanwa kuisa dhizaini yeprimer kana primer pamusoro pesimbi isina tsvina yekumusoro kuti uvandudze kunamatira kwemavara ekupfeka uye kuve nechokwadi chekufanana.

3. Nano color coating mafuta: Nano color coating mafuta ndeye yakasarudzika coating inoumbwa nanoparticles. Izvi zvimedu zvinogadzira kukanganisa uye kuparadzira mhedzisiro pasi pechiedza chemwenje, zvichigadzira mavara akasiyana. Saizi uye kurongeka kwezvimedu izvi zvinogona kugadziridzwa kuti uwane inodiwa ruvara maitiro.

4.Kurapa nekuomesa: Mushure mekushandisa iyo nano color coating, iyo simbi isina tsvina ndiro inowanzoda kurapwa uye kuomeswa pasi pemamiriro akakodzera kuti ive nechokwadi chekuti kuvharwa kwemavara kwakanyatso kusungirirwa pamusoro.

5. Kudzora kwehutano: Mushure mekupedzwa kwekuputira uye kuomeswa, kutonga kwemhando yesimbi isina tsvina mahwendefa anodiwa kuti ave nechokwadi chekufanana kwemavara, kunamatira uye kusimba.

6. Packaging uye Delivery: Kana yangopfuura kudzora kwemhando, mahwendefa esimbi asina mavara anogona kuiswa uye kuendeswa kumutengi kana mugadziri kuti ashandise kwekupedzisira.

Nano color oil tekinoroji inobvumira kutaridzika kwemavara pasina kushandiswa kwemavara echinyakare uye nekudaro yakakurumbira mukushongedza, dhizaini uye zvigadzirwa zvepamusoro. Iyi nzira inowanzoshandiswa munzvimbo dzakadai sezvishongo, mawachi, kushongedza kwekuvaka, uye zvigadzirwa zvemagetsi zvepamusoro.

Mhedziso

Stainless simbi ine mavara mahwendefa ane akawanda anogona kushandiswa. Bata Hermes Steel nhasi kuti udzidze zvakawanda nezve zvigadzirwa zvedu, uye masevhisi kana kuwana emahara masampuli. Tingafara kukubatsira kuwana mhinduro yakakwana yezvido zvako. Ndapota inzwa wakasunungukaTAURA NESU

Nguva yekutumira: Sep-14-2023