Ngophuhliso lwamaxesha, abantu abaninzi ngakumbi bakhetha intsimbi enemibala engenanto njengesixhobo sokuhombisa, kwaye lo mkhwa uya ubonakala ngakumbi.

Iindlela ezintathu ezixhaphakileyo zokufaka umbala kwiipleyiti ezinombala wentsimbi engenasici

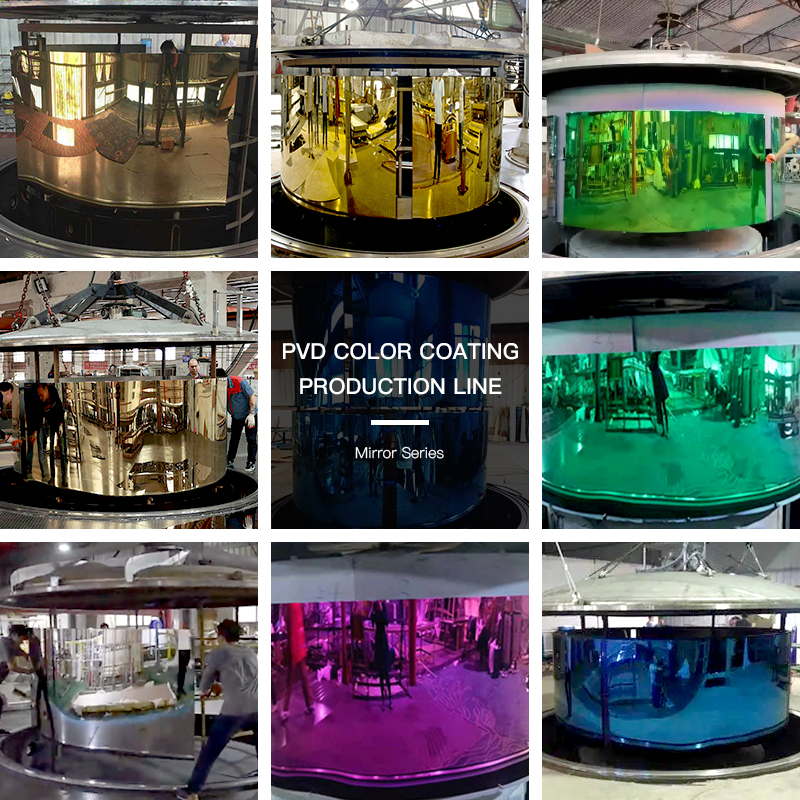

1. Ukucoca ngevacuum

Inkqubo: Ukufakwa kombala kwenziwa kwindawo ye-vacuum kwiqondo lokushisa elithile kunye nexesha.

Iimpawu: Ubume bendalo, ukuthungwa kakuhle kwesinyithi, ixesha elide kunye nombala oqaqambileyo

Imibala ye-plating eqhelekileyo: i-titanium emnyama (emnyama eqhelekileyo), igolide ye-titanium, igolide enkulu, igolide ye-champagne, i-rose yegolide, i-bronze ephuzi, i-burgundy, i-brown, i-brown, isafire eluhlaza, i-emerald eluhlaza, imibala e-7, njl.

ipleyiti yombala wentsimbi engenasiciyindlela yokuncamathelisa ifilimu okanye ukwambathisa kumphezulu wentsimbi engenasici ukuze itshintshe umbala wayo nenkangeleko. Le nkqubo ibandakanya ukubeka ipleyiti yensimbi engenasici kwigumbi le-vacuum kwaye emva koko ifake ifilimu okanye i-coating phezu komhlaba phantsi kweemeko ze-vacuum. Nanga amanyathelo ngokubanzi:

1. Lungisa umphezulu wensimbi engenasici: Okokuqala, umgangatho wensimbi ongenasici kufuneka ulungiswe ukuqinisekisa ukuba umgangatho ucocekile kwaye awukho ukungcola, igrisi, okanye ezinye izinto ezingcolileyo. Oku kunokwenziwa ngokucoca imichiza okanye unyango ngoomatshini.

2.Ukusetwa kwegumbi lokufunxa: Isitya sensimbi esingenasici sifakwe kwigumbi lokucoca, eliyindawo evaliweyo enokulawula uxinzelelo lwangaphakathi kunye nomoya. Ngokuqhelekileyo kukho itafile ejikelezayo ezantsi kwegumbi lokucoca elijikeleza ipleyiti yensimbi engenasici ukuqinisekisa ukufakwa okufanayo.

3.Ukufudumeza: Kwigumbi le-vacuum, iipleyiti zensimbi ezingenasici zinokuthi ziphathwe ubushushu ukuze kuphuculwe ukunamathela komphezulu kwiifilimu okanye kwiingubo. Ukufudumala kwakhona kunceda ngokufakwa okufanayo kwefilimu.

4. Ukubekwa kwefilimu encinci: Ngaphantsi kweemeko ze-vacuum, izinto ezifunekayo zefilimu ezinqabileyo (ngokuqhelekileyo isinyithi okanye ezinye iikhompawundi) zikhutshwa ngumphunga okanye zitshizwe kwindawo yensimbi engenasici. Oku kunokufezekiswa ngeendlela ezinje nge-electron beam evaporation, i-magnetron sputtering, i-chemical vapour deposition, njl. Emva kokuba iifilimu zifakwe, zenza i-coating efanayo kumphezulu wensimbi engenasici.

5. Ukupholisa kunye nokuqinisa: Emva kokuba ifilimu ifakwe, i-plate yensimbi engenasici kufuneka ipholile kwaye iqiniswe kwigumbi lokucoca ukuze kuqinisekiswe ukuba i-coating ibambelele ngokuqinileyo ebusweni. Le nkqubo inokwenziwa ngaphakathi kwegumbi lokucoca.

6. Ulawulo lwemeko: Emva kokugqitywa kokubekwa kunye nokunyanga, ukulawulwa komgangatho weeplati ezinemibala yensimbi engenasici kufuneka kuqinisekiswe ukuba umbala kunye nokubonakala kuhambelana neemfuno.

7. Ukupakishwa kunye nokuhanjiswa: Emva kokuba idlulise ukulawulwa kwekhwalithi, i-electroplated steel stainless color plates inokupakishwa kwaye ihanjiswe kumthengi okanye umenzi wokusetyenziswa kokugqibela.

I-vacuum electroplating yeepleyiti zensimbi engenasici inokufezekisa imibala eyahlukeneyo kunye neziphumo, kwaye ihombisa kakhulu kwaye ihlala ixesha elide. Le ndlela isoloko isetyenziswa kwiindawo ezinjengomhlobiso ophezulu, ubucwebe kunye nokuveliswa kweewotshi ukutshintsha ukubonakala kwensimbi engenasici.

2. Ukufakwa kwamanzi

Inkqubo: Ukufakwa kombala kwizisombululo ezithile

Iimpawu: Ayinabungozi ngokwaneleyo kokusingqongileyo, imibala yokucwenga elinganiselweyo

Imibala ye-plating eqhelekileyo: i-titanium emnyama (imnyama), ubhedu, ubhedu obomvu, njl.

Amanyathelo ngokubanzi okufakwa kwamanzi kwiipleyiti ezinemibala yentsimbi engatyiwayo:

Unyango lomphezulu: Okokuqala, umphezulu weplate yensimbi engenasici kufuneka ihlambuluke kwaye iphathwe ukuze kuqinisekiswe ukuba akukho grisi, ukungcola okanye ezinye izinto ezingcolileyo. Eli nyathelo libaluleke kakhulu njengoko liqinisekisa ukufana kunye nokunamathela kwenkqubo yokudaya elandelayo.

Unyango lwangaphambili: Phambi kokufakwa kwamanzi, umphezulu wensimbi engenasici udla ngokufuna ukulungiswa kwangaphambili okukhethekileyo ukunyusa ukuncamathela kwebala. Oku kunokubandakanya ukufaka umaleko wolwelo oluphambi konyango kumphezulu ukwenza kube lula ukufunxa umbala.

Ukufakwa kwamanzi: Inyathelo eliphambili lokutyalwa kwamanzi libandakanya ukusebenzisa i-liquid yokudaya (ngokuqhelekileyo isekelwe emanzini) equkethe i-pigments kunye neekhemikhali kwindawo yensimbi engenasici. Olu lwelo lokudaya lusenokuba nedayi yombala othile, i-agent ekhupha i-oxidizing, kwaye mhlawumbi ne-diluent. Xa ulwelo oludayayo ludibana nomphezulu wensimbi engenasici, kubakho ukusabela kweekhemikhali, okubangela ukuba umbala unamathele kumphezulu.

Ukunyanga kunye nokomisa: Iipaneli ezidayiweyo zensimbi ezingenasici ngokuqhelekileyo zifuna ukuphiliswa kwaye zomiswe phantsi kweemeko ezifanelekileyo ukuqinisekisa ukuba umbala uqinile kwaye uqinile. Oku kunokubandakanya amanyathelo afana nokufudumeza okanye ukomisa umoya.

Ulawulo lwemeko: Emva kokugqitywa kokudaya kunye nokumisa, ukulawulwa komgangatho weeplati zensimbi ezingenasici ziyafuneka. Oku kubandakanya ukujonga ukufana kombala, ukunamathela, ukuqina kunye neziphene ezinokwenzeka.

Ukupakishwa kunye nokuhanjiswa: Emva kokuba idlulise ulawulo lomgangatho, iiplati zensimbi ezidayiweyo zensimbi ezingenasici zingapakishwa kwaye zihanjiswe kumthengi okanye umenzi wokusetyenziswa kwazo ekupheleni.

3. Ioli yombala weNano

Inkqubo: Umphezulu unombala ngeoli ye-nano-color, efana nokutshiza phezulu

Iimpawu: 1) Phantse nawuphi na umbala unokuba yi-electroplated

2) Umbala onokwenziwa ngobhedu lokwenene

3) Akukho ukhuseleko lweminwe emva kokuba ioli yombala iza nayo

4) Ubume bentsimbi bubi kakhulu

5) Ubume bomphezulu bugutyungelwe kwinqanaba elithile

Imibala yokucwenga eqhelekileyo: Phantse nawuphi na umbala unokubekwa

steel stainless umbala ipleyiti nano umbala oyilesisigqubuthelo sombala esilungiselelwe kusetyenziswa i-nanotechnology, edla ngokusetyenziswa kumphezulu wentsimbi engenasici ukuphumeza inkangeleko enemibala. Le ndlela isebenzisa imiphumo yokusabalalisa kunye nokuphazamiseka kwe-nanoparticles ekukhanyeni ukuvelisa imibala eyahlukeneyo kunye nemiphumo. Nanga amanyathelo olungiselelo ngokubanzi:

1. Unyango lomphezulu: Indawo yensimbi engenasici kufuneka ihlanjululwe kwaye ilungiswe ukuze kuqinisekiswe ukuba umgangatho ucocekile kwaye awunayo igrisi, ukungcola okanye ezinye izinto ezingcolileyo. Eli linyathelo elibalulekileyo lokuqinisekisa ukunamathela kokutyabeka.

2. Ukwambathisa kokuqala: Ngaphambi kokuba i-oyile yombala we-nano ifakwe, ngokuqhelekileyo kuyimfuneko ukusebenzisa uluhlu lwe-primer okanye i-primer kwindawo yensimbi engenasici ukuze kuphuculwe ukunamathela kombala wombala kunye nokuqinisekisa ukufana.

3. Nano umbala oyile ukutyabeka: I-oyile yombala we-Nano yingubo ekhethekileyo eyenziwe ngama-nanoparticles. Ezi ngqungquthela ziya kuvelisa ukuphazamiseka kunye nemiphumo yokusabalalisa phantsi kwe-irradiation yokukhanya, ngaloo ndlela yenze ukubonakala kwemibala eyahlukeneyo. Ubungakanani kunye nokulungelelaniswa kwezi ngqungquthela zinokutshintshwa ukuze kuphunyezwe umphumo ofunekayo wombala.

4.Ukunyanga kunye nokomisa: Emva kokufaka i-oyile yombala we-nano, i-plate yensimbi engenasici ngokuqhelekileyo ifuna ukuphiliswa kwaye yomiswe phantsi kweemeko ezifanelekileyo ukuqinisekisa ukuba umbala wombala unamathele ngokuqinileyo phezu komhlaba.

5. Ulawulo lwemeko: Emva kokugqitywa kokugqoka kunye nokumisa, ukulawulwa komgangatho weeplati zensimbi ezingenasici zifunekayo ukuze kuqinisekiswe ukufana kombala, ukunamathela kunye nokuqina.

6. Ukupakishwa kunye nokuhanjiswa: Emva kokuba idlulise ukulawulwa komgangatho, iipleyiti zensimbi ezingenasici ezinombala zingapakishwa kwaye zihanjiswe kumthengi okanye umenzi wokusetyenziswa kokugqibela.

I-teknoloji yeoli ye-Nano ivumela ukubonakala kwemibala ngaphandle kokusetyenziswa kwee-pigments zendabuko kwaye ngoko ke ithandwa kakhulu kwimihlobiso, ukuyila kunye neemveliso eziphezulu. Le ndlela isetyenziswa ngokuqhelekileyo kwiindawo ezifana nobucwebe, iiwotshi, umhombiso wokwakha, kunye neemveliso ze-elektroniki eziphezulu.

Ukuqukumbela

Iipleyiti ezinemibala yensimbi engenasici enezicelo ezininzi ezinokubakho. Qhagamshelana neHermes Steel namhlanje ukuze ufunde ngakumbi malunga neemveliso zethu, kunye neenkonzo okanye ufumane iisampulu zasimahla. Siya kukuvuyela ukukunceda ufumane isisombululo esifanelekileyo kwiimfuno zakho. Nceda uzive ukhululekileQHAGAMSHELANA NATHI

Ixesha lokuposa: Sep-14-2023