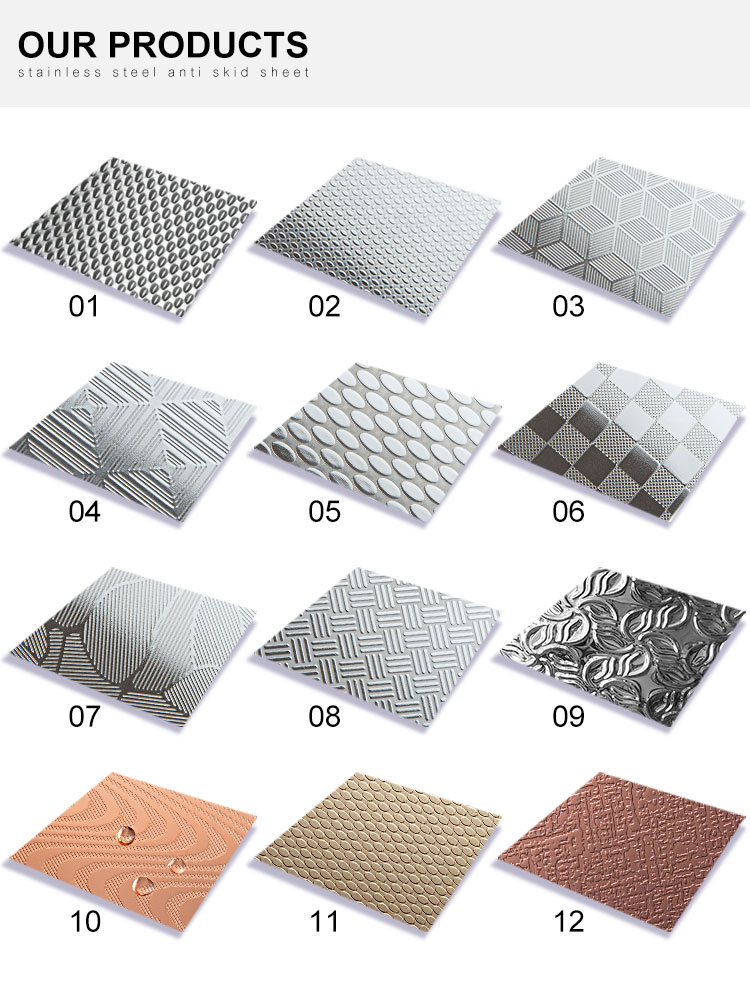

Covstainless hlau embossing phajyog embossed ntawm stainless hlau phaj los ntawm cov khoom siv kho tshuab, kom lub ntsej muag ntawm lub phaj nthuav tawm cov qauv concave thiab convex. Nrog rau txoj kev loj hlob ntawm lub teb chaws kev lag luam thiab kev lag luam innovation, kev siv stainless hlau embossing phaj yog tsis txwv rau cov kws tshaj lij thiab kev lag luam kev siv cov khoom siv los tiv thaiv xeb, thiab cov khoom siv tshiab yog siv rau cov tsheb thauj mus los, elevator kho kom zoo nkauj, kho kom zoo nkauj vaj tse, hlau kab hlau rhuav phab ntsa, dab dej khob, cov khoom siv hauv tsev, cov khoom siv hluav taws xob thiab lwm yam. Nws qhov zoo muaj xws li durability, durability, hnav-resistant, muaj zog zoo nkauj nyhuv, pom kev zoo nkauj, yooj yim los ntxuav, txij nkawm-dawb, tsis kam, siab tsis kam, khawb kuj thiab tsis muaj ntiv tes.

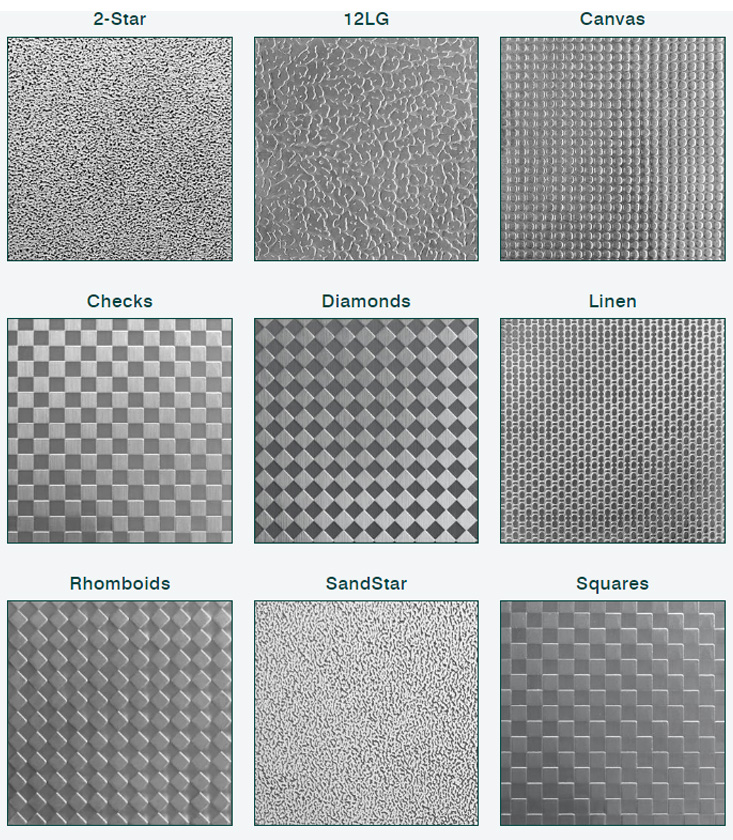

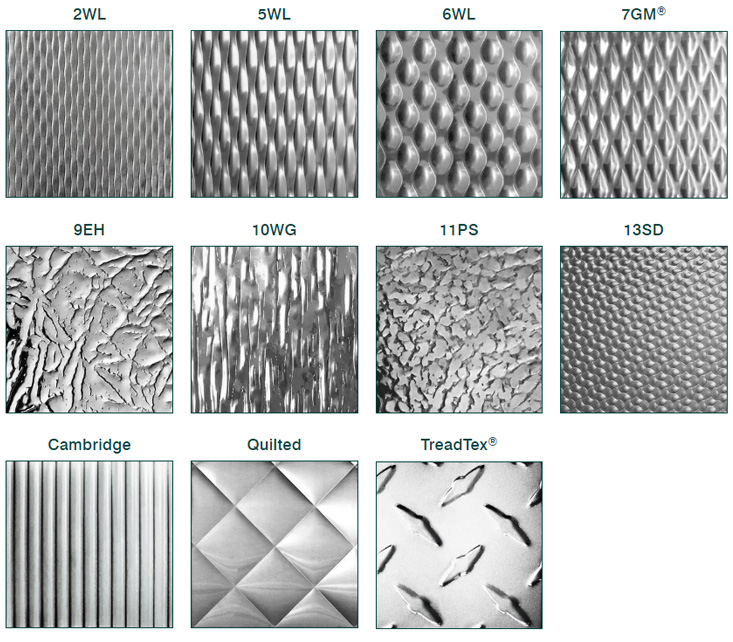

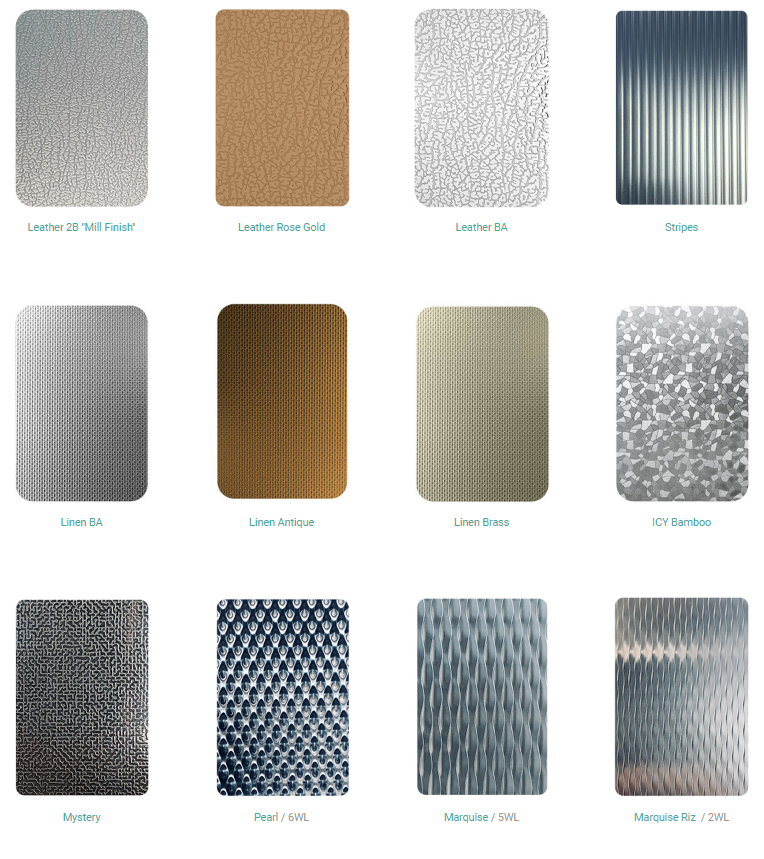

Stainless hlau emboweling phaj qauv muaj nplej nplej, pob zeb diamond, sawb, daim phiaj, tawv qauv thiab lwm yam, feem ntau siv cov ntaub ntawv yog 201, 202, 304 thiab 316, thiab lwm yam. Lub thickness ntawm cov hlau phaj yog 0.3 ~ 2.0 hli, lub emboweling qhov tob yog 20 ~ 50um, feem ntau yog dov los ntawm ib tug phaj los yog BA. Vim hais tias stainless hlau embossing phaj muaj cov kev xav tau siab heev rau cov duab thiab qhov loj ntawm cov qauv thiab qhov siab sib txawv (uniformity) ntawm cov qauv, thiab cov kev lag luam sib txawv muaj cov kev xav tau sib txawv rau cov gloss, zoo li, mechanical zog thiab corrosion kuj ntawm embossing phaj, nws ntau lawm nyuaj.

Qhov zoo ntawmstainless hlau embossed ntawv:

Txheej txheem tsim:

Qhov txias dov tsim ntawm stainless hlau embossed phaj yog ob theem dov, txoj kev tshwj xeeb yog:raw khoom annealing pickling, ntxhib dov, ntxhib sib tsoo, nruab nrab dov, intermediate annealing, nplua dov, ci annealing, straightening thiab tiav cov khoom

Ntawm lawv: 1. Cov ntaub ntawv nyoos los ua kom cov txheej txheem sib tsoo sib tsoo kom tshem tawm cov kab nrib pleb ntawm qhov tsis xws luag, txhim kho cov khoom zoo, thaum tsis txhob cuam tshuam cov khoom siv raw hauv qhov kev puas tsuaj tom ntej ntawm cov menyuam cov qauv. 2. Tom qab ua tiav dov embossing hniav embossing phaj raws li cov kev xav tau ntawm cov neeg siv los txiav txim siab seb puas yuav annealing dua, cov khoom embossing phaj yuav tsum muaj zoo formability tom qab embossing yuav tsum tau annealed.

Txheej txheem ntawm cov menyuam:

Nyob rau hauv tus txheej txheem ntawm embossing stainless hlau, kev ua haujlwm ntawm kev sib cuag ncaj qha ntawm tus qauv rau cov menyuam thiab cov kab nrib pleb yog sib npaug rau kev ua haujlwm zoo ntawm "tuag" qauv cov menyuam, qhov tseeb ntawm cov qauv loj, thiab cov txheej txheem ua haujlwm ncaj qha cuam tshuam rau qhov zoo ntawm cov phaj embossing thiab kev pab cuam lub neej ntawm tus qauv menyuam.

Rolling txheej txheem:

1.System Configuration Requirements

Nyob rau hauv lub dov ntawm embossed phaj, lub Upper ua hauj lwm yob siv cov qauv yob thiab cov qis ua hauj lwm yob siv lub tiaj yob. Vim tias nws yog ib leeg-sab embossed, muaj qhov sib txawv tseem ceeb hauv qhov txuas ntxiv ntawm sab sauv thiab sab qis, yog tias tsis tswj tau, cov sawb yuav tshwm sim loj heev, thiab nws yog ib qho nyuaj rau smoothly dhau lub phaj thaum lub teeb ci ntawm cov txheej txheem tom ntej yog annealed. Lub warping ntawm embossed phaj tuaj yeem tswj tau nyob rau hauv qhov tsim nyog ntau yam los ntawm kev xyuas kom meej tias qhov sib txawv ntawm txoj kab uas hla ntawm cov yob ua haujlwm sab saud thiab qis qis yog ib qho nqi thiab qhov roughness ntawm cov yob qis yog tswj tau.

2. Qauv qhov siab lav

Qhov siab ntawm cov qauv yog ib qho tseem ceeb zoo Performance index ntawm embossing phaj. Cov qauv ntawm cov hlau phaj yog tsim los ntawm qhov zawj ntawm cov hlau ntim rau hauv cov yob thaum lub sij hawm dov txheej txheem. Qhov siab ntawm tus qauv yog nyob ntawm seb cov hlau ntws mus rau hauv qhov zawj thiab qhov nyiaj ntawm cov hlau ntws mus rau hauv qhov zawj yog nyob ntawm qhov siab ntawm qhov embossed dhau [1]. Nyob rau hauv txoj kev loj hlob ntawm txias dov txheej txheem ntawm stainless hlau embossed phaj, rau txawv steel qib thiab cov qauv, nws yog ib qhov tsim nyog los ua kom paub qhov sib raug zoo ntawm tus nqi txo qhov tseeb thiab qhov siab ntawm tus qauv. Cov ntaub ntawv yog cuam tshuam los ntawm cov tshuaj muaj pes tsawg leeg ntawm raw cov ntaub ntawv thiab cov txheej txheem tsis nyob rau hauv lub upstream txheej txheem, thiab cov txheej txheem tsis xws li raw cov ntaub ntawv muaj pes tsawg leeg, intermediate annealing kub thiab annealing ceev yuav tsum nruj me ntsis tswj thiab tswj nyob rau hauv ntau lawm kom nws ruaj khov thiab txo cov kev hloov pauv. Tom qab cov yam ntxwv cuam tshuam tau raug kho, qhov txias dov txo tus nqi ntawm embossing dhau tuaj yeem txiav txim siab raws li qhov siab ntawm tus qauv.

Tus qauv qhov siab ntawm stainless hlau embossing phaj yog feem ntau 20-50 m thaum txo tus nqi tswj ntawm 5% thiab 16%. On-site ntau lawm tuaj yeem hloov kho me ntsis raws li qhov ntsuas qhov ntsuas qhov siab.

Yog tias koj txaus siab rau peb cov khoom thiab xav paub ntau ntxiv, thov sau ntawv rau ntawm no, thiab peb yuav teb koj sai li sai tau.

Post lub sij hawm: Jun-16-2023