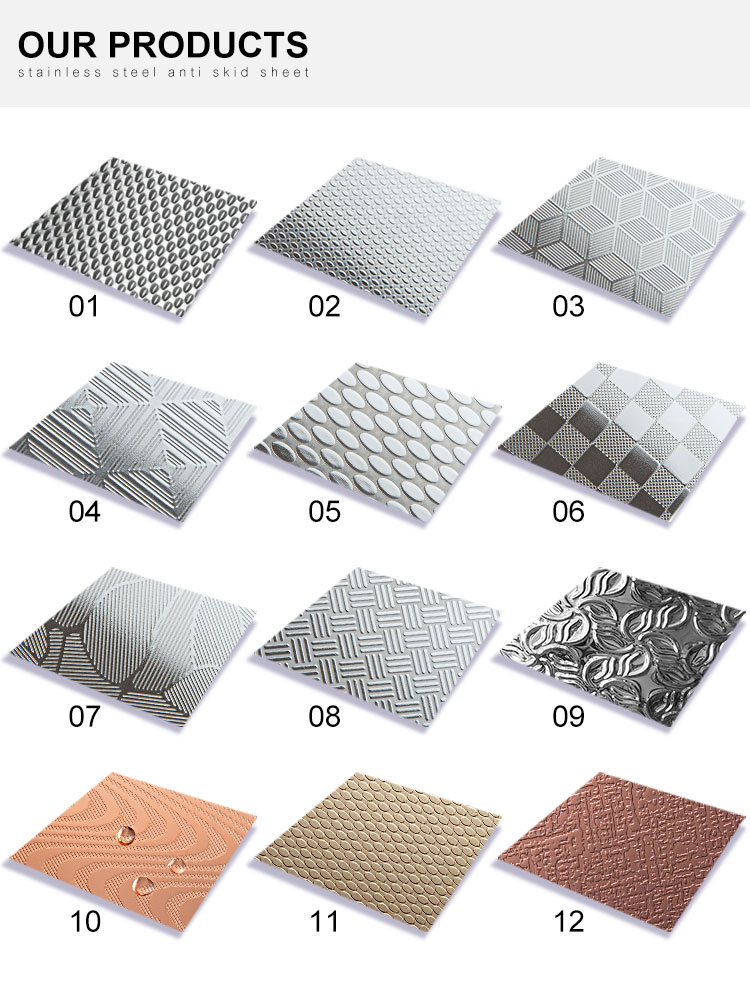

The stainless steel embossing plate is embossed on the stainless steel plate by mechanical equipment, so that the surface of the plate presents a concave and convex pattern. With the development of the national economy and industry innovation, the use of stainless steel embossing plate is no longer limited to the professional fields and industry applications of anti-slip and anti-corrosion, and more innovative products are applied to subway cars, elevator decoration, architectural decoration, metal curtain wall, sink cups, household appliance panels, light industrial products and other industries. Its advantages include durability, durability, wear-resistant, strong decorative effect, visual beauty, easy to clean, maintenance-free, resistance, pressure resistance, scratch resistance and leave no finger marks.

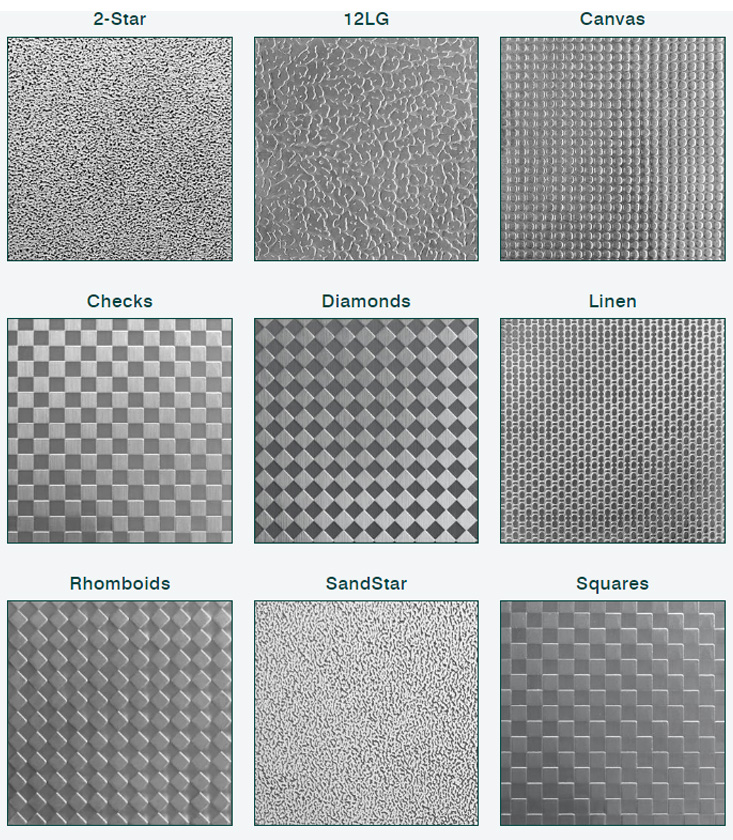

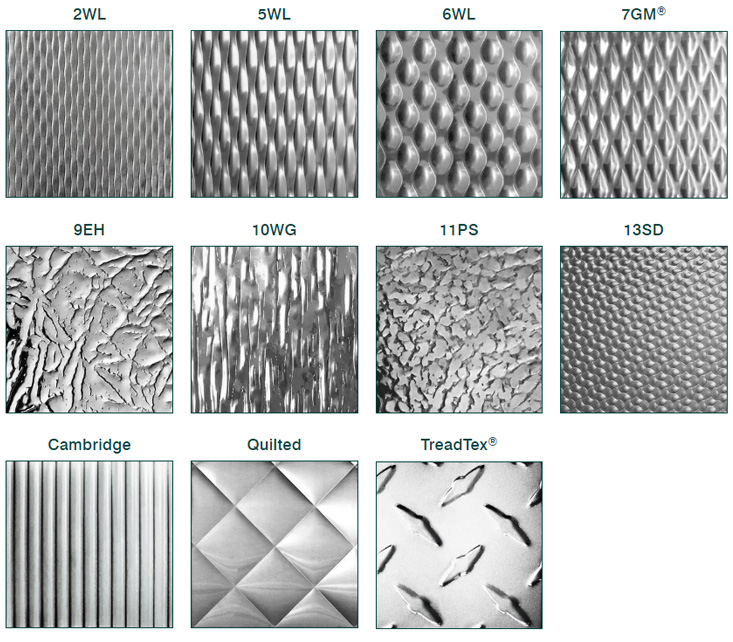

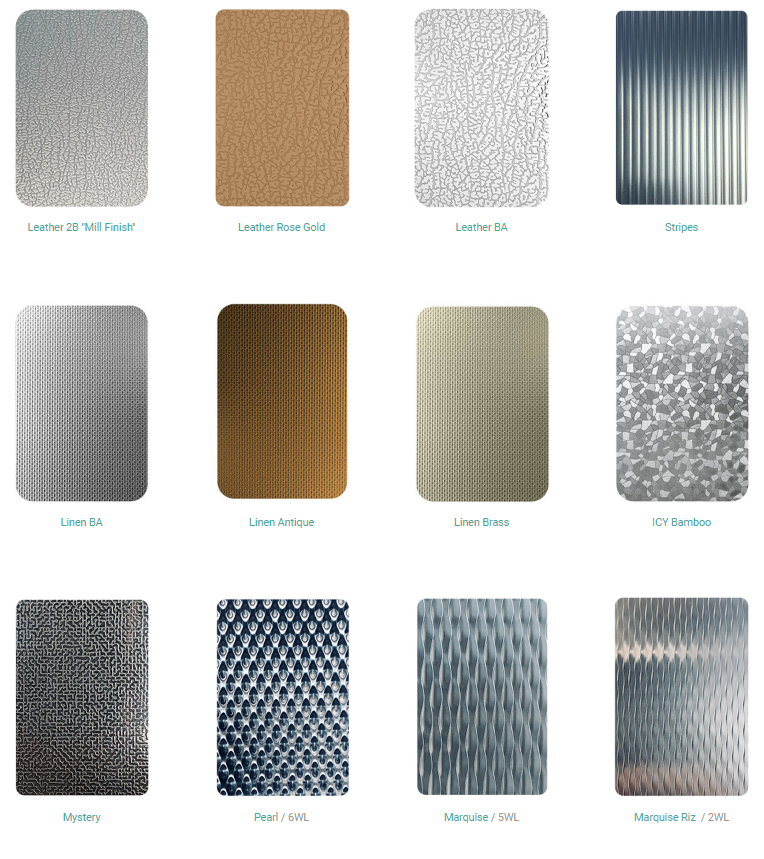

Stainless steel emboweling plate pattern has rice grain, diamond, strip, grid, leather pattern and other styles, commonly used materials are 201, 202, 304 and 316, etc. The thickness of the steel plate is 0.3~ 2.0mm, the emboweling depth is 20~ 50um, generally rolled by a roller with a pattern on the 2B plate or BA plate (bright plate). Because the stainless steel embossing plate has very high requirements for the shape and size of the pattern and the height difference (uniformity) of the pattern, and different industries have different requirements for the gloss, shape, mechanical properties and corrosion resistance of the embossing plate, its production is more difficult.

Advantages of stainless steel embossed sheet:

Process design:

The cold rolling design of stainless steel embossed plate is two rolling stages, the specific path is: raw material annealing pickling, rough rolling, rough grinding, intermediate rolling, intermediate annealing, fine rolling, bright annealing, straightening and finished product

Among them :1. Raw materials to increase rough rolling rough grinding process to eliminate strip surface defects, improve product quality, while avoiding raw material defects in the subsequent rolling damage to the roller pattern. 2. After finishing rolling embossing decorative embossing plate according to the needs of users to decide whether to annealing again, product embossing plate requirements have good formability after embossing need to be annealed.

Processing of pattern roller:

In the process of embossing stainless steel, the function of direct contact between the pattern roller and the strip surface is equivalent to the processing quality of the “die” pattern roller, the precision of the pattern size, and the processing method directly affect the rolling quality of the embossing plate and the service life of the pattern roller.

Rolling process setting:

1.System Configuration Requirements

In the rolling of embossed plate, the upper work roll uses the pattern roll and the lower work roll uses the flat roll. Because it is single-sided embossed, there is a significant difference in the extension of the upper and lower surfaces, if not controlled, the strip will appear serious warping, and it is difficult to smoothly pass the plate when the bright unit of the next process is annealed. The warping of embossed plate can be controlled within a reasonable range by ensuring that the diameter difference of the upper and lower work rolls is a certain value and the roughness of the lower roll is controlled

2. Pattern height guarantee

The height of pattern is an important quality index of embossing plate. The pattern on the surface of the steel plate is formed by the groove of the metal filled into the roll during the rolling process. The height of the pattern depends on the amount of metal flowing into the groove and the amount of metal flowing into the groove depends on the amount of pressure of the embossed pass [1]. In the development of cold rolling process of stainless steel embossed plate, for different steel grades and patterns, it is necessary to master the corresponding relationship between the actual reduction rate and the height of the pattern. The data is affected by the chemical composition of raw materials and the process parameters of the upstream process, and the process parameters such as raw material composition, intermediate annealing temperature and annealing speed should be strictly controlled and managed in production to ensure its stability and reduce fluctuations. After the influence factors are relatively fixed, the cold rolling reduction rate of embossing passes can be determined according to the height of the pattern

The pattern height of stainless steel embossing plate is generally 20-50 m when the reduction rate is controlled between 5% and 16%. On-site production can be slightly adjusted according to the measurement results of the pattern height.

If you are interested in our products and would like to know more details, please leave a message here, and we will reply to you as soon as we can.

Post time: Jun-16-2023