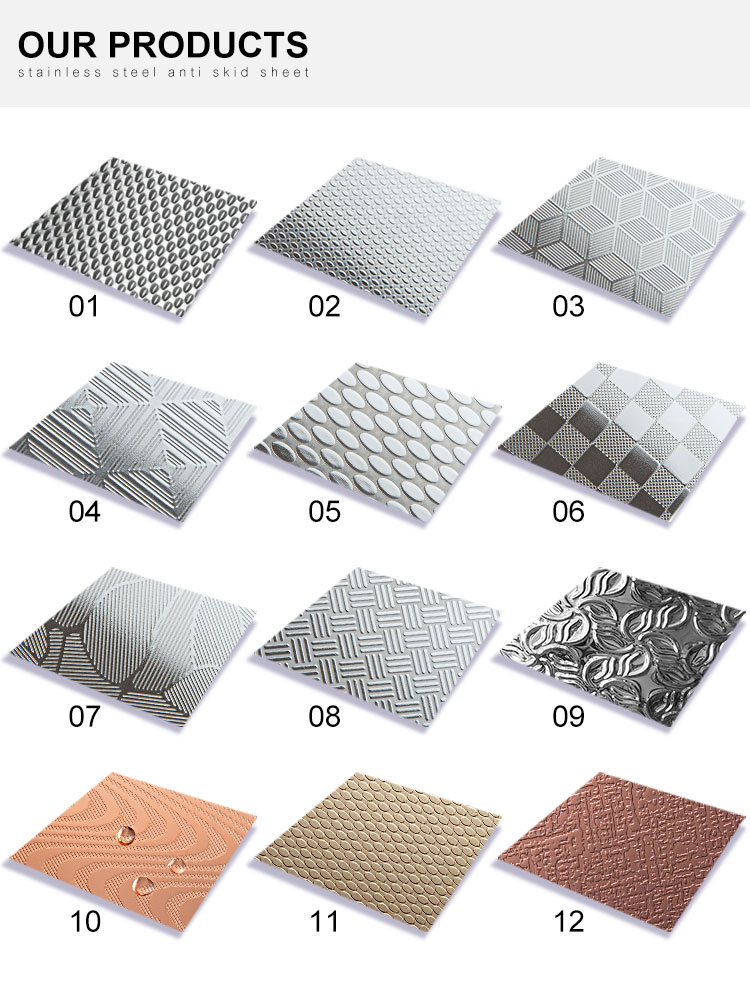

Iinsimbi engagqwali embossing ipuletiiqoshwe epuletini lensimbi engagqwali ngomshini, ukuze indawo engaphezulu yepuleti iveze iphethini ye-concave ne-convex. Ngokuthuthuka komnotho kazwelonke kanye nokusha kwemboni, ukusetshenziswa kwepuleti lokunamathisela lensimbi engagqwali akusakhawulelwe emikhakheni yobungcweti kanye nezicelo zemboni ze-anti-slip kanye ne-anti-corrosion, futhi imikhiqizo emisha isetshenziswa ezimotweni ezingaphansi komhlaba, umhlobiso we-lifti, umhlobiso wezakhiwo, udonga lwamakhethini ensimbi, izinkomishi zikasinki, amaphaneli ezinto zasendlini, imikhiqizo yezimboni kanye neminye imikhiqizo yezimboni. Izinzuzo zayo zihlanganisa ukuqina, ukuqina, ukumelana nokugqoka, umphumela wokuhlobisa onamandla, ubuhle obubonakalayo, ukuhlanza okulula, ukunganakekeli, ukumelana, ukumelana nokucindezela, ukumelana nokuklwebheka futhi kungashiyi izimpawu zeminwe.

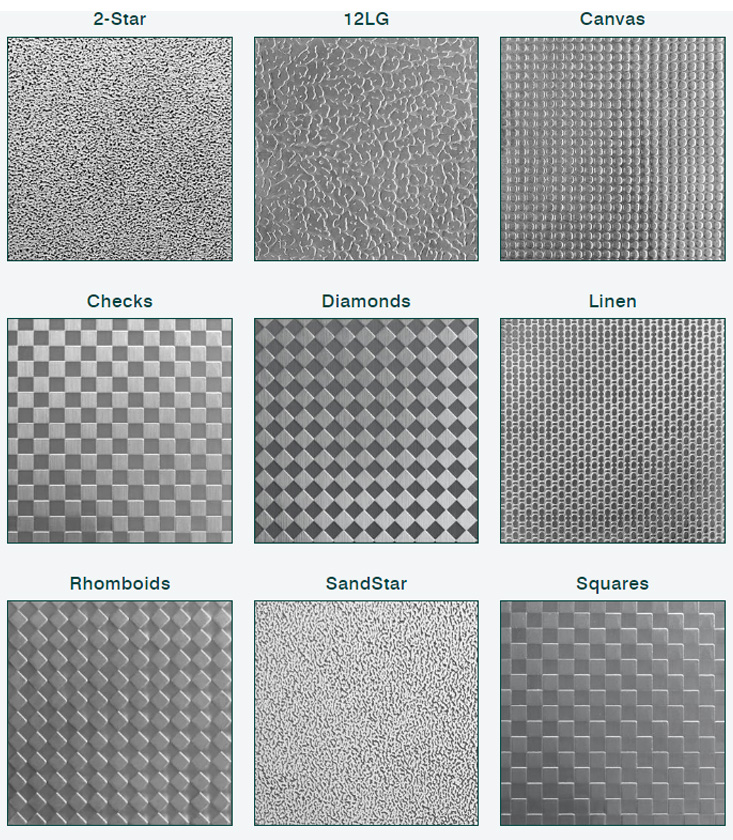

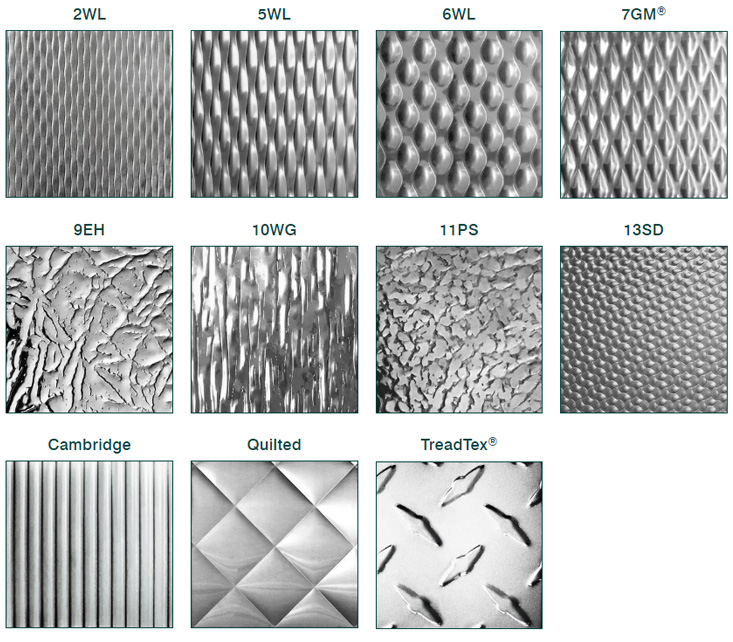

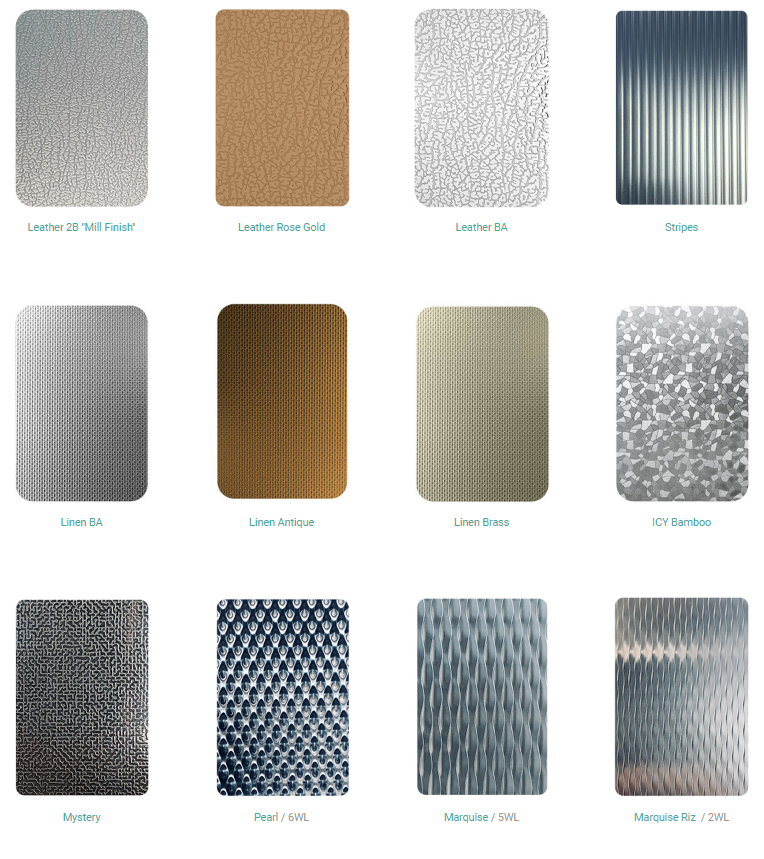

Iphethini yepuleti lensimbi engagqwali inohlamvu zelayisi, idayimane, umugqa, igridi, iphethini yesikhumba nezinye izitayela, izinto ezisetshenziswa ngokuvamile ziyi-201, 202, 304 kanye no-316, njll. Ugqinsi lwepuleti lensimbi lingu-0.3~ 2.0mm, ukujula kwe-embowelling kungu-20~ 50um, ipuleti eligoqelwe nge-rolling engu-2b ngokuvamile nge-BA noma ipuleti). Ngenxa yokuthi i-stainless steel embossing plate inezidingo eziphakeme kakhulu zokuma nobukhulu bephethini kanye nomehluko wokuphakama (ukufana) kwephethini, futhi izimboni ezahlukene zinezidingo ezihlukene ze-gloss, umumo, izakhiwo zemishini kanye nokumelana nokugqwala kwepuleti lokunamathisela, ukukhiqizwa kwayo kunzima kakhulu.

Izinzuzo zeinsimbi engagqwali embossed sheet:

Idizayini yenqubo:

Idizayini ebandayo egoqayo yensimbi engagqwali embossed plate yizigaba ezimbili eziginqikayo, indlela ethize yilena:i-raw material annealing pickling, ukugoqa okungalungile, ukugaya okumahhadlahhadla, ukugoqeka okumaphakathi, ukudonsa okuphakathi nendawo, ukugoqa kahle, ukudonsa okukhanyayo, ukuqondisa nomkhiqizo oqediwe

Phakathi kwabo :1. Izinto zokusetshenziswa zokukhulisa inqubo yokugaya ukuze kuqedwe ukonakala kwendawo, kuthuthukiswe ikhwalithi yomkhiqizo, kuyilapho kugwenywa ukonakala kwempahla eluhlaza emonakalweni wokugoqeka olandelayo wephethini yerola. 2. Ngemva kokuqeda ukugoqa ipuleti lokunamathisela lokuhlobisa ngokwezidingo zabasebenzisi ukuze banqume ukuthi baphinde bafakwe yini i-anneal, izidingo zepuleti lokugqamisa umkhiqizo zinokwakheka okuhle ngemva kwesidingo sokufakwa kwe-embossing.

Ukucutshungulwa kwe-roller yephethini:

Enqubweni yokugqamisa insimbi engagqwali, umsebenzi wokuthintana okuqondile phakathi kwerola yephethini nendawo ewumugqa ulingana nekhwalithi yokucubungula yerola yephethini "efa", ukunemba kosayizi wephethini, kanye nendlela yokucubungula kuthinta ngqo ikhwalithi yokugoqa yepuleti lokunamathisela kanye nempilo yesevisi yerola yephethini.

Isilungiselelo senqubo yokugoqa:

1.Izidingo Zokucushwa Kwesistimu

Ekugoqeni kwepuleti eligxiviziwe, umqulu wokusebenza ongaphezulu usebenzisa umqulu wephethini bese umqulu wokusebenza ophansi usebenzisa i-flat roll. Ngenxa yokuthi iqoshwe ohlangothini olulodwa, kunomehluko omkhulu ekwandiseni izindawo ezingaphezulu neziphansi, uma zingalawulwa, umugqa uzovela u-warping okungathi sína, futhi kunzima ukudlulisa kahle ipuleti lapho iyunithi ekhanyayo yenqubo elandelayo ikhishwa. Ukungqubuzana kwepuleti eliqoshiwe kungalawulwa ngaphakathi kwebanga elifanele ngokuqinisekisa ukuthi umehluko wobubanzi wamaroli okusebenza aphezulu naphansi uyivelu ethile futhi ukugoba kwe-roll engezansi kuyalawulwa.

2. Isiqinisekiso sobude bephethini

Ukuphakama kwephethini kuyinkomba yekhwalithi ebalulekile yepuleti lokunamathisela. Iphethini ebusweni bepuleti lensimbi lakhiwa i-groove yensimbi egcwaliswe ku-roll phakathi nenqubo yokugoqa. Ukuphakama kwephethini kuncike enanini lensimbi egeleza emgodini kanye nenani lensimbi eligeleza emgodini lincike emalini yokucindezela kokudlula okuqoshiwe [1]. Ekuthuthukisweni kwenqubo yokugoqa ebandayo yepuleti eqoshiwe yensimbi engenasici, kumamaki ensimbi ahlukene namaphethini, kuyadingeka ukwazi ubudlelwano obuhambisanayo phakathi kwezinga langempela lokunciphisa kanye nokuphakama kwephethini. Idatha ithintwa ukwakheka kwamakhemikhali wezinto zokusetshenziswa kanye nemingcele yenqubo yenqubo ekhuphuka nomfula, futhi amapharamitha enqubo afana nokubunjwa kwempahla eluhlaza, izinga lokushisa eliphakathi nendawo kanye nesivinini sokukhipha isisu kufanele kulawulwe ngokuqinile futhi kulawulwe ekukhiqizeni ukuze kuqinisekiswe ukuzinza kwayo nokunciphisa ukushintshashintsha. Ngemuva kokuthi izici zethonya sezilungisiwe ngokuqhathaniswa, izinga lokunciphisa ukugoqa okubandayo lokudlula kwe-embossing linganqunywa ngokuya ngobude bephethini.

Ubude bephethini yepuleti lokunamathisela lensimbi engagqwali ngokuvamile lingama-20-50 m lapho izinga lokunciphisa lilawulwa phakathi kuka-5% no-16%. Ukukhiqizwa kwesayithi kungalungiswa kancane ngokuya ngemiphumela yokulinganisa yobude bephethini.

Uma unentshisekelo ngemikhiqizo yethu futhi ungathanda ukwazi imininingwane eyengeziwe, sicela ushiye umlayezo lapha, futhi sizokuphendula ngokushesha ngangokunokwenzeka.

Isikhathi sokuthumela: Jun-16-2023