TheStainless steel embossing ndiroinonamirwa pandiro yesimbi isina tsvina nemichina yemidziyo, kuitira kuti pamusoro peplate iratidze patani ye concave uye convex. Nekuvandudzwa kwehupfumi hwenyika uye hunyanzvi hweindasitiri, kushandiswa kwesimbi isina tsvina embossing ndiro haichaganhurirwe kuminda yehunyanzvi uye maindasitiri ekushandisa anti-slip uye anti-corrosion, uye zvimwe zvigadzirwa zvitsva zvinoiswa kumotokari dzepasi pevhu, kushongedza kweelevator, kushongedza kwekuvaka, simbi yemaketeni emadziro, sink makapu, mapaneru emidziyo yemumba, zvigadzirwa zvemaindasitiri emagetsi nezvimwe. Zvakanakira zvaro zvinosanganisira kusimba, kusimba, kusapfeka-resistant, yakasimba yekushongedza mhedzisiro, inooneka runako, nyore kuchenesa, kuchengetedza-isina, kuramba, kumanikidza kuramba, kukwenya kuramba uye kusasiya mavanga emunwe.

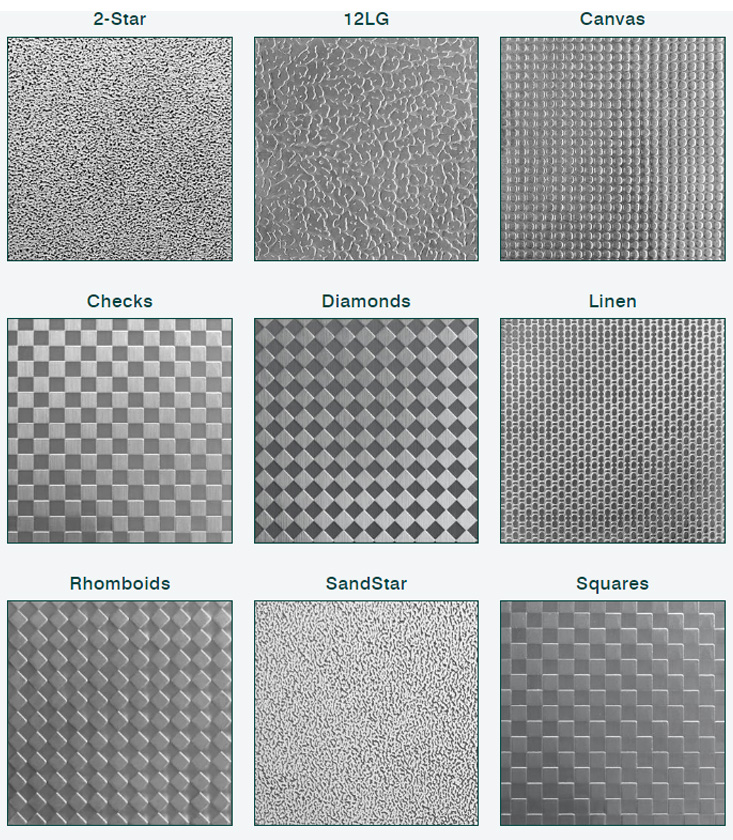

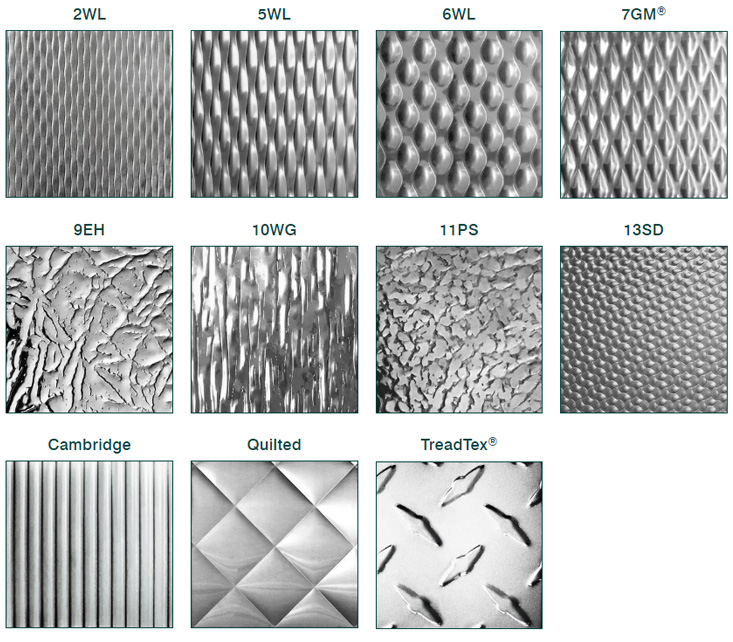

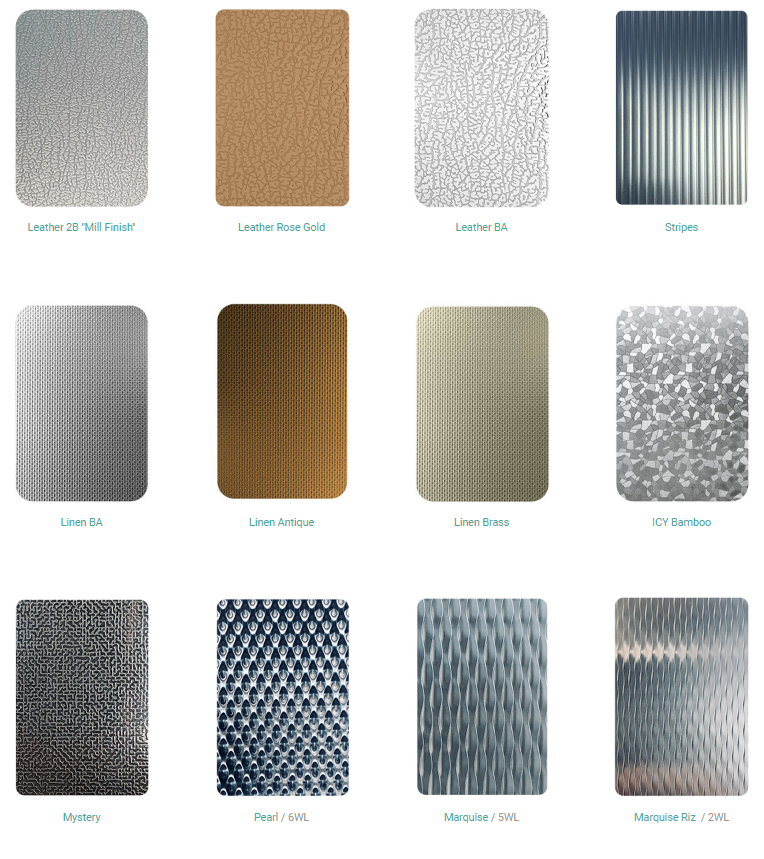

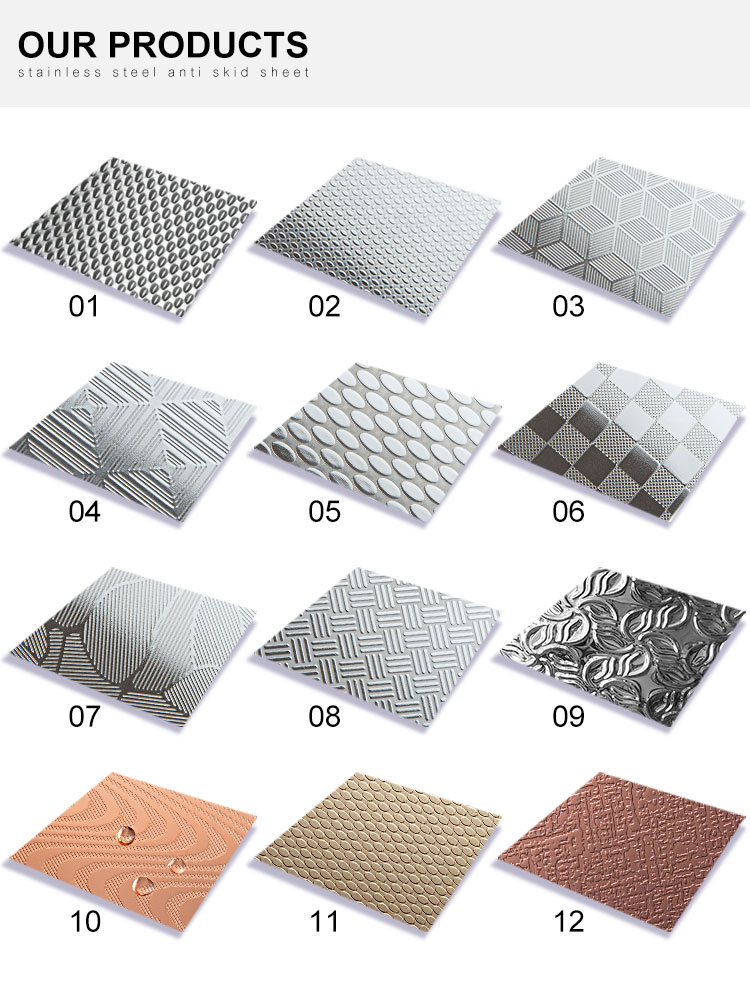

Stainless steel emboweling plate pattern ine mupunga zviyo, diamond, strip, grid, dehwe pateni nemamwe masitayera, zvinowanzoshandiswa zvinhu 201, 202, 304 uye 316, etc. Ukobvu hwendiro yesimbi i0.3 ~ 2.0mm, kudzika kwe emboweling i20 ~ 50um, kazhinji kacho ine roller Bright patani neBA. Nemhaka yokuti ndiro yesimbi isina tsvina ine zvidikanwi zvakanyanya zvechimiro uye saizi yemuenzaniso uye mutsauko wehurefu (kufanana) kwemuenzaniso, uye maindasitiri akasiyana ane zvinodiwa zvakasiyana kune gloss, chimiro, mechanical properties uye kupesana nekuora kweplate embossing, kugadzirwa kwayo kunonyanya kuoma.

Zvakanakira zvesimbi isina tsvina yakanamirwa sheet:

Process design:

Iyo inotonhora yekutenderedza dhizaini yesimbi isina simbi yakamisikidzwa ndiro matanho maviri ekutenderera, iyo chaiyo nzira ndeiyi:raw material annealing pickling, rough rolling, rough grinding, intermediate rolling, intermediate annealing, fine rolling, bright annealing, straightening and finished product.

Pakati pavo :1. Raw materials yekuwedzera rough rolling rough grinding process kuti ibvise hurema hwe strip, kunatsiridza kunaka kwechigadzirwa, uku uchidzivirira hurema hwezvinhu zvakakanyiwa mukukuvara kunotevera kukunguruka kune roller pateni. 2. Mushure mekupedza kutenderedza embossing yekushongedza embossing ndiro zvinoenderana nezvinodiwa nevashandisi kuti vasarudze kana annealing zvakare, chigadzirwa embossing plate zvinodiwa zvine chimiro chakanaka mushure mekunyora kunoda kuvharwa.

Kugadziriswa kwepattern roller:

Mukuita embossing simbi isina tsvina, basa rekubatana kwakananga pakati pepattern roller uye strip surface yakaenzana nekugadziriswa kwemhando ye "die" pattern roller, kurongeka kwehukuru hwemuenzaniso, uye nzira yekugadzira inobata zvakananga kunaka kwekutenderera kweplate ye embossing uye hupenyu hwebasa hwepateni roller.

Rolling process setting:

1.System Configuration Zvinodiwa

Mukukungurutswa kwendiro yakanamirwa, iro repamusoro rebasa rinoshandisa patani roll uye rezasi rekushanda rinoshandisa flat roll. Nekuda kwekuti ine divi rimwe chete rakamisikidzwa, pane mutsauko wakakura mukuwedzera kwekumusoro uye kwepasi nzvimbo, kana ikasadzorwa, tambo inotaridzika yakakomba, uye zvinonetsa kupfuudza mundiro mushe kana iyo inopenya yechikamu chinotevera chavharwa. Iyo warping ye embossed plate inogona kudzorwa mukati mehumwe hunoenderana nekuona kuti dhayamita mutsauko wepamusoro uye wepasi webasa rolls ndeyehumwe kukosha uye kushata kweiyo yakaderera roll inodzorwa.

2. Muenzaniso urefu vimbiso

Kureba kwepateni ndiyo yakakosha yemhando index ye embossing plate. Chimiro chiri pamusoro peplate yesimbi inoumbwa ne groove yesimbi yakazadzwa mumupumburu panguva yekugadzira. Kureba kwepateni kunoenderana nehuwandu hwesimbi inoyerera ichipinda mugoro uye huwandu hwesimbi inoyerera ichipinda mugororo zvinoenderana nehuwandu hwekumanikidzwa kweiyo embossed pass [1]. Mukuvandudzwa kwekutonhora kwekukunguruka kwesimbi isina tsvina yakanamirwa ndiro, kune akasiyana simbi mamakisi uye mapatani, zvinodikanwa kugona hukama hunoenderana pakati peiyo chaiyo yekudzikisa mwero uye kureba kwepateni. Iyo data inokanganiswa nekemikari yezvigadzirwa zvezvakagadzirwa uye maparamendi eiyo nzira yekumusoro, uye maparamita ekuita senge rakagadzirwa zvinhu, yepakati annealing tembiricha uye annealing kumhanya kunofanirwa kudzorwa nekudzorwa mukugadzira kuti ive nechokwadi chekugadzikana kwayo uye kuderedza kushanduka. Mushure mekuti pesvedzero zvinhu zvakati dzikamei, kutonhora kudonhedza kudzikisa mwero we embossing passes inogona kutariswa zvichienderana nehurefu hwepateni.

Kureba kwepateni yesimbi isina tsvina embossing ndiro inowanzoita 20-50 m kana mwero wekudzikisa uchidzorwa pakati pe5% ne16%. Pa-saiti kugadzirwa kunogona kugadziridzwa zvishoma zvichienderana nechiyero chemhedzisiro yehurefu hwepateni.

Kana iwe uchifarira zvigadzirwa zvedu uye uchida kuziva rumwe ruzivo, ndapota siya meseji pano, uye isu tichakupindura iwe nekukurumidza sezvatinogona.

Nguva yekutumira: Jun-16-2023