Amashidi ensimbi engagqwali asetshenziswa kakhulu ezimbonini eziningi ngenxa yokuqina kwawo, ukumelana nokugqwala kanye nokuqedwa kwendawo okubushelelezi. Kodwa-ke, ngenxa yobukhulu bawo obuhlukene, amashidi ensimbi engagqwali adinga ukudlula izinqubo eziningi ezakhiweni, futhi lezi zinqubo zingahluka kuye ngephrojekthi.

Ukusika amashidi ensimbi engagqwali kudinga ukukhetha indlela efanele yokusika ngokusekelwe ebukhulu beshidi, izidingo zokunemba namathuluzi atholakalayo. Nali inkomba ehlelekile:

1. Izinto okufanele zicatshangelwe lapho usika insimbi engagqwali

Insimbi engagqwali inselele ukuyisika ngenxa yezici zayo, ezithinta ukusika ukusebenza kahle. Izinkinga ezinjengokuqina okuncishisiwe kwempahla, ukumelana nokushisa kwayo kanye namathuluzi asetshenziselwa ukusika kuyavela:

Izinto ezibonakalayo

Insimbi engagqwali iqinile futhi imelana namakhemikhali, okwenza ifanelekele izinhlelo eziningi zokusebenza, kodwa kunzima ukuyibumba. Ukushisa okwedlulele ngesikhathi sokusika kungabangela ukuba kukhubazeke, kuyilapho ubulukhuni bayo bubangela ukuguga ngokushesha kwethuluzi.

Ukujiya kweshidi

Ubunjalo bomsebenzi buncike ebukhulu bezinto ezibonakalayo, amashidi amancane angasikwa ngesandla noma ngemishini emincane, kuyilapho amashidi aminyene adinga imishini emikhulu efana nokusika i-plasma noma ukusika indiza yamanzi. Ukuphatha okushisayo kubalulekile.

Ukusika ithuluzi ukuqina

Ngenxa yezici zensimbi engagqwali, amathuluzi akhethekile afana ne-carbide noma amathuluzi e-laser yezimboni ayadingeka ekusikeni. Kubalulekile ukuthi la mathuluzi akhethekile akwazi ukusika ngokukhululekile ngaphandle kokudala umonakalo ensimbi engagqwali ngesikhathi sokusika.

Ukuphatha okushisayo

Njengoba lokhu kunzima, amathuluzi afanelekile afana namathuluzi e-carbide nama-lasers ezimboni ayadingeka. Basebenzisa imishini ekhethekile yokusika ukuze bathole imiphumela engcono ngenkathi begwema ukulimala kwemishini ngesikhathi sokusika.

Izidingo zokunemba

Ngokuya ngezidingo zephrojekthi, ukunemba okuphezulu kakhulu kuchaza amathuluzi wokusika kanye namasu. Ama-laser noma ama-jet cutter amanzi angenza ukusikeka okuhle, kuyilapho ukusikeka okulula, amathuluzi alula njengama-shears noma isikele asetshenziselwa ukusika amashidi amancane.

2. Ukukhetha ithuluzi nokushuba okusebenzayo

Amashidi azacile (≤1.2mm, njengezansi kwegeji engu-18)

Amathuluzi esandla

Izikebhe zezindiza (izikere zethini): ifanele ukusika okuqondile noma okugobile, ukusebenza okuguquguqukayo kodwa okukhandlayo, kudinga ukusika ezingxenyeni ezincane ukunciphisa ukuguqulwa; ilungele amaphrojekthi amancane.

Izikebhe zikagesi (Nibbler): ukusika ngokushaya izingxenye ezincane zezinto ezibonakalayo, ezifanele izimo eziyinkimbinkimbi, ukunciphisa i-warping ne-deformation.

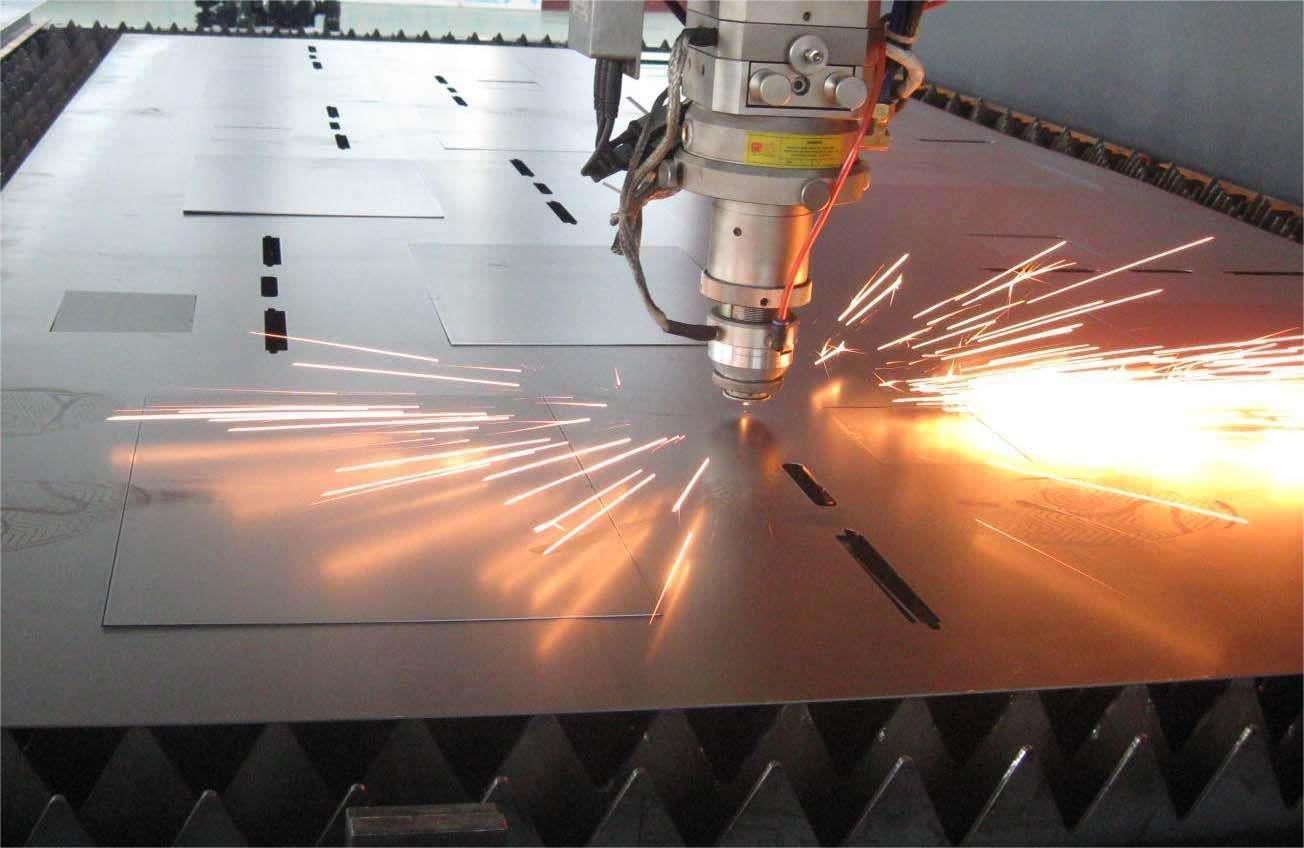

Ukusika i-Laser: ukunemba okuphezulu, i-burr-free, ifanele izidingo zezimboni, kodwa idinga ukusekelwa kwemishini yochwepheshe.

Imikhuba emihle kakhulu

››Yehlisa ukushisa

Ngokuvamile, insimbi encane engagqwali iyakwazi ukushisa, ibangele ukungqubuzana noma ukushintsha kombala. Uma usebenzisa isivinini esilungile sethuluzi futhi, uma kunesidingo, izinto zokupholisa ezifana nokusika amajethi oketshezi namanzi, ungakwazi ukugwema lokhu ngempumelelo.

››Azinzise iphepha

Qinisekisa ukuthi igxilile endaweni ukuze isikwe futhi uqinisekise ukuthi ayinyakazi ngenkathi isebenza. Lokhu kuzogwema ukudlula ezindaweni ezingafanele futhi kubangele imihuzuko eminingi eshidini; okuholela ekusikeni okungcono, okuhlanzekile, nokunembe kakhudlwana.

››Hlulisa unqenqema

Ubukhali busho ukuthi kungenzeka kube khona amachopho acijile noma amadlangala ohlamvu nangaphansi kwendawo ngemva kokusika. Kunconywa ukusebenzisa ithuluzi lokususa noma i-sandpaper ukuze ukwazi ukusika ngokuphepha futhi uzuze ukubukeka okufunayo.

Amapuleti aphakathi nendawo futhi awugqinsi (1.2-3mm, njengaphansi kuka-1/8 intshi)

Amathuluzi amandla

I-Jig saw (ene-bimetallic saw blade): Sebenzisa i-18-24 TPI isaha iblade enamazinyo amahle, usike ngesivinini esiphansi futhi usebenzise isipholile ukuze uphole ukuze ugweme ukushisa ngokweqile kanye nokuqina.

Isaha eliyindilinga (i-carbide blade): Udinga ukusebenzisa irula eliqondisayo ukuze uqinisekise ukusika okuqondile, fafaza uwoyela wokusika ukuze unciphise ukungqubuzana.

Ukusika i-Plasma: Ifanele ukusika ngokushesha kwamapuleti awugqinsi, kodwa idinga i-compressor yomoya kanye nempahla yokuzivikela, futhi ukusika kungase kudinge ukupholishwa.

Ubuchwepheshe bokupholisa: Ukushisa akukaze kube yinkinga ngensimbi engagqwali, kodwa inqubo yokupholisa ngesikhathi sokusika ingase ibangele ukuwohloka noma ukukhathala. Amathuluzi afana namanzi, umoya kanye noketshezi lokusika anganciphisa ukuguga kwezinto, ngaleyo ndlela athuthukise ukuqina kwe-blade.

Amapuleti awugqinsi (≥3mm, afana ne-intshi engu-1/4 nangaphezulu)

I-Angle grinder (isondo lokugaya elikhethekile lensimbi engagqwali): ukusika isivinini esimaphakathi, gwema izinga lokushisa eliphezulu elibangela ukuqina kwempahla, futhi ugqoke izinto zokuzivikela.

Umsiki wePlasma: ifanele indawo yezimboni, idinga i-compressor yomoya kanye nemishini yokuzivikela, ukusika okuphumelelayo kwamapuleti aminyene.

Ukusika i-laser/water jet: ayikho indawo ethintekile ekushiseni, ukunemba okuphezulu kakhulu, ifanele ukucutshungulwa kokunemba okuphezulu kobumo obuyinkimbinkimbi, kodwa izindleko ziphezulu.

Ukusika uketshezi kanye nokugcoba: Izisheli ze-hydraulic zifaneleka kakhulu ekusikeni komugqa oqondile wensimbi engenasici ye-gauge encane, ikakhulukazi kumapuleti aminyene. Izikena zeHydraulic ziyakwazi ukufaka ingcindezi enkulu ukuze kufinyelelwe ukusikeka okuhlanzekile nokuncane ngesikhathi esifushane, ngakho-ke zilungele izinhlelo zokusebenza ezidinga umsebenzi omningi.

Amathiphu: Ukusika amapuleti ensimbi engagqwali aminyene, izisika ze-plasma, amasistimu ejethi yamanzi, namalaser wezimboni kumele asetshenziselwe ukugcina ikhwalithi yezinto. Kuyaziwa ukuthi ukupholisa umoya nokugcinwa njalo kungathuthukisa ukusebenza nokuqina.

3. Amakhono okusebenza abalulekile

Ukulawula izinga lokushisa

Insimbi engagqwali ine-thermal conductivity engalungile futhi iqina kalula noma ikhubazekile ngenxa yokushisa okuphezulu. Sebenzisa okokupholisa (okufana namafutha okusika) noma indlela yokuphakelayo ekhuphukayo ukuze unciphise izinga lokushisa lokusika futhi welule impilo yamathuluzi.

Gwema ukusika ngokuqhubekayo ngesivinini esiphezulu futhi umise kancane ukuchithwa kokushisa ngezikhathi ezifanele ukuze uvimbele ukushisa kwasendaweni.

Ukuthuthukisa ithuluzi nepharamitha

Izinto zamathuluzi: I-Carbide noma i-cobalt equkethe amathuluzi ensimbi enesivinini esiphezulu ayakhethwa ukuze kube ngcono ukumelana nokugqoka.

Ukusika imingcele: Isivinini esiphansi kanye ne-torque ephezulu (njengalapho ubhoboza), nezithambisi zokuthuthukisa ukuqedwa kwendawo.

Imodi yokuphakelayo: Ukudla okwandayo (ukusika okungaqhubeki) kunganciphisa ukunqwabelana kokushisa futhi kunciphise izinga lokushisa ngaphezu kuka-30% uma kuqhathaniswa nokuphakelayo kweradial.

Ukwelashwa okulandelayo

Ukukhipha imali: Pholisha ukusika ngefayela, i-sandpaper noma i-angle grinder ukuze uqinisekise ukuphepha nobuhle.

Ukuhlanza i-pickling: Uma udinga ukususa isikali se-oxide, sebenzisa i-asidi exubile (njenge-HNO₃+HF) ukuze uqoke, kodwa isikhathi kufanele silawulwe ukuze ugweme ukugqwala okukhulu.

4. Izici zezinto kanye nezindlela zokuzivumelanisa nezimo

Insimbi engagqwali ye-Austenitic (njenge-304/316): i-ductility eqinile, kulula ukunamathela kummese, idinga ithuluzi lobulukhuni obuphezulu kanye nokupholisa okwanele.

Insimbi engagqwali equkethe i-molybdenum (efana ne-316): ukumelana nokugqwala okuphezulu, kodwa ukumelana nokusika okuphezulu, kunconywa ukusebenzisa isivinini esiphansi nge-high lubricity coolant.

Uhlobo olulula ukusikwa (njengo 303): iqukethe izakhi zesulfure noma i-selenium, ezingakhuphula isivinini sokusika, ukunciphisa ukugqoka kwamathuluzi, futhi ifanele ukucubungula ngesivinini esikhulu.

5. Ukuphepha nokugcinwa

Ukuvikelwa komuntu siqu: izibuko, amagilavu amelana nokusikwa, imaski yothuli (ukugwema ukuhogela uthuli lwensimbi).

Ukuhlolwa kwemishini: shintsha njalo ama-blade agugile/amasondo okugaya ukuqinisekisa ukusika ukusebenza kahle nokuphepha.

Ukuphathwa kwemvelo: gcina umoya, gwema izinto ezivuthayo, futhi uhlanze imfucumfucu yensimbi ngesikhathi.

Isifinyezo: Ukusika amapuleti ensimbi engagqwali kudinga ukucatshangelwa okuphelele kokuqina, izimo zempahla kanye nethuluzi, okubekwe kuqala ekulawuleni izinga lokushisa nokuguga kwamathuluzi. Ngezidingo zokunemba okuphezulu, kunconywa ukuthi kukhishwe i-laser/jet jet cutting; ekusebenzeni kwansuku zonke, amathuluzi e-carbide + okupholisayo + okuphakelayo okwandayo yizixazululo ezisebenzayo kakhulu. Qiniseka ukuthi ujwayelene namasu okusika amancane, aphakathi nendawo futhi awugqinsi, futhi unake izilinganiso zokusika ezihlanzekile, eziphephile nezinembayo ukuze uqinisekise ukuthi konke ukusika akunasici.

Isikhathi sokuthumela: May-10-2025