Amashiti entsimbi asetyenziswa kakhulu kumashishini amaninzi ngenxa yokuqina kwawo, ukuxhathisa kokubola kunye nokugqiba komphezulu ogudileyo. Nangona kunjalo, ngenxa yobunzima bawo obahlukeneyo, amashiti ensimbi engenasici kufuneka ahambe kwiinkqubo ezininzi ekwakhiweni, kwaye ezi nkqubo zinokwahluka kwiprojekthi ukuya kwiprojekthi.

Ukusika amacwecwe ensimbi engenasici kufuna ukukhetha indlela efanelekileyo yokusika ngokusekelwe kubukhulu bephepha, iimfuno zokuchaneka kunye nezixhobo ezikhoyo. Nasi isikhokelo esicwangcisiweyo:

1. Izinto ekufuneka ziqwalaselwe xa usika intsimbi engenasici

Insimbi engenasici inzima ukusika ngenxa yeempawu zayo, ezichaphazela ukusika ukusebenza kakuhle. Imiba efana nokuncipha kobulukhuni bezinto eziphathekayo, ukumelana nobushushu kunye nezixhobo ezisetyenziselwa ukusika ziza ngaphambili:

Iimpawu zezinto eziphathekayo

Insimbi engenasici inzima kwaye iyamelana neekhemikhali, iyenza ifaneleke kwizicelo ezininzi, kodwa kunzima ukuyilolonga. Ukushisa okugqithisileyo ngexesha lokusika kunokubangela ukuba kukhubazeke, ngelixa ubunzima bayo bubangela ukuguga ngokukhawuleza kwesixhobo.

Ubukhulu bephepha

Ubume bomsebenzi buxhomekeke kubukhulu bezinto eziphathekayo, amashiti amancinci anokunqunyulwa ngesandla okanye ngoomatshini abancinci, ngelixa amashidi ashinyeneyo afuna oomatshini abakhulu njengokusika kweplasma okanye ukusika ijethi yamanzi. Ulawulo lobushushu lubalulekile.

Ukusika isixhobo ukuqina

Ngenxa yeempawu zensimbi engenasici, izixhobo ezikhethekileyo ezifana ne-carbide okanye izixhobo ze-laser zamashishini zifunekayo ukusika. Kubalulekile ukuba ezi zixhobo ezikhethekileyo zinqumle ngokukhululekileyo ngaphandle kokubangela umonakalo kwinsimbi engenasici ngexesha lokusika.

Ulawulo lobushushu

Ekubeni oku kunzima, izixhobo ezifanelekileyo ezifana nezixhobo ze-carbide kunye ne-laser zamashishini ziyafuneka. Basebenzisa izixhobo ezikhethekileyo zokusika ukuphumeza iziphumo ezingcono ngelixa bephepha umonakalo kwisixhobo ngexesha lokusika.

Iimfuno zokuchaneka

Ngokuxhomekeke kwiimfuno zeprojekthi, ukuchaneka okuphezulu kuchaza izixhobo zokusika kunye nobuchule. I-Laser okanye i-jet cutters yamanzi ingenza ukusika okulungileyo, ngelixa ukusika okulula, izixhobo ezilula ezifana ne-shears okanye i-scissors zisetyenziselwa ukusika amaphepha amancinci.

2. Ukukhetha isixhobo kunye nobunzima obusebenzayo

Amaphepha abhityileyo (≤1.2mm, afana nangaphantsi kwe-18 geji)

Izixhobo zesandla

Izikere zeAviation (izikere zenkcenkce): ilungele ukusika okuthe tye okanye okugobileyo, okuguquguqukayo kodwa okusebenzayo, kufuneka kunqunywe kumacandelo amancinci ukunciphisa ukuguqulwa; zilungele iiprojekthi ezincinci.

Izikere zombane (Nibbler): ukusika ngokubetha amacandelo amancinci ezinto eziphathekayo, ezifanelekileyo kwiimilo ezinzima, ukunciphisa i-sheet warping kunye ne-deformation.

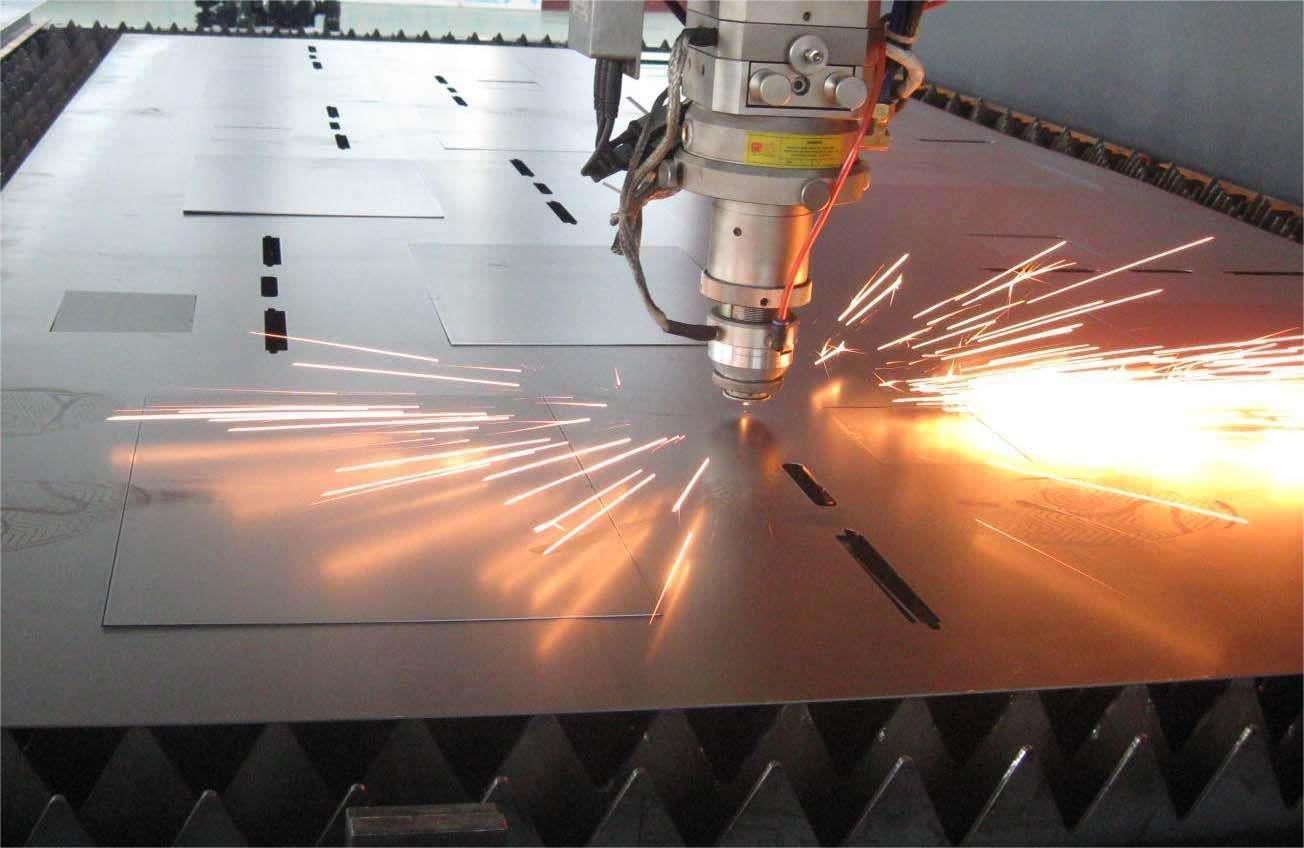

Ukusika kweLaser: ukuchaneka okuphezulu, i-burr-free, ilungele iimfuno zamashishini, kodwa ifuna inkxaso yezixhobo zobungcali.

Iinkqubo ezigqwesileyo

›› Yehlisa ubushushu

Ngokubanzi, intsimbi ecekeceke engenastainless ichaphazeleka bubushushu, ibangele i-warping okanye i-discoloration. Ukuba usebenzisa isantya sesixhobo esifanelekileyo kwaye, ukuba kuyimfuneko, izipholileyo ezifana nokusika ulwelo kunye neejethi zamanzi, unokukwazi ukukuphepha ngokufanelekileyo oku.

››Zinzise iphepha

Qinisekisa ukuba igxininiswe ngokuqinileyo kumphezulu ukuze isikwe kwaye uqinisekise ukuba ayishukumi ngelixa isebenza. Oku kuya kuphepha ukuhamba kwiindawo ezingafanelekanga kwaye kubangele imikrwelo engaphezulu kwiphepha; okukhokelela ekusikeni okungcono, okucocekileyo, kunye nokuchaneka ngakumbi.

›› Khupha ungqameko

Ububukhali bubhekiselele kumacala abukhali okanye uburhabaxa kwiinkozo nakumazantsi ommandla emva kokusikwa. Kucetyiswa ukuba usebenzise isixhobo sokuhlamba okanye i-sandpaper ukwenzela ukuba unqande ngokukhuselekileyo kwaye ufezekise ukubonakala okufunayo.

Amacwecwe aphakathi kunye atyebileyo (1.2-3mm, anje ngaphantsi kwe-1/8 intshi)

Izixhobo zamandla

I-Jig saw (ene-bimetallic saw blade): Sebenzisa i-18-24 TPI i-saw blade enamazinyo acocekileyo, usike ngesantya esiphantsi kwaye usebenzise isipholileyo ukupholisa ukuphepha ukutshisa kunye nokuqina.

Isarha yesarha (incakuba yecarbide): Kufuneka usebenzise irula yesikhokelo ukuqinisekisa ukusika ngokuthe tye, ukutshiza ioli yokusika ukunciphisa ukungqubuzana.

Ukusika iplasma: Ifanelekile ukusika ngokukhawuleza kweeplate ezishinyeneyo, kodwa ifuna i-compressor yomoya kunye nezixhobo zokukhusela, kwaye ukusika kunokufuneka kuphuculwe.

Itekhnoloji yokupholisa: Ubushushu abusoze bube yingxaki kwintsimbi engenastainless, kodwa inkqubo yokupholisa ngexesha lokusika inokubangela ukuguquka okanye ukudinwa. Izixhobo ezifana namanzi, umoya kunye nokusika ulwelo kunokunciphisa ukunxiba kwizinto eziphathekayo, ngaloo ndlela kuphuculwe ukuqina kwe-blade.

Iipleyiti ezityebileyo (≥3mm, ezinje nge-intshi eyi-1/4 nangaphezulu)

I-Angle grinder (ivili lokusila elikhethekileyo lentsimbi engatyiwayo): ukusika isantya esiphakathi, thintela ukushisa okuphezulu okubangela ukuqina kwezinto, kwaye unxibe izixhobo zokukhusela.

Umsiki wePlasma: ilungele indawo yoshishino, ifuna i-compressor yomoya kunye nezixhobo zokukhusela, ukusika ngokufanelekileyo kweeplate ezishinyeneyo.

I-laser / ijethi yamanzi yokusika: akukho ndawo ichaphazelekileyo kubushushu, ukuchaneka okuphezulu kakhulu, ilungele ukusetyenzwa okuphezulu kweemilo ezintsonkothileyo, kodwa ixabiso liphezulu.

Ukusika ulwelo kunye nokuthambisa: Izikere ze-Hydraulic zifaneleke kakhulu ukusika umgca othe tye we-thin-gauge stainless steel stainless, ngakumbi kwiiplate ezishinyeneyo. Izikere zeHydraulic ziyakwazi ukufaka uxinzelelo olukhulu ekufezekiseni ukusikwa okucocekileyo kunye nokubhityileyo ngelona xesha lifutshane, ngoko ke zilungele izicelo ezifuna umsebenzi omninzi.

Iingcebiso: Ukusika iipleyiti zentsimbi eshinyeneyo, izisiki zeplasma, iinkqubo zejethi zamanzi, kunye neelasesi zemizi-mveliso kufuneka zisetyenziswe ukugcina umgangatho wezinto. Kuyaziwa ukuba umoya kunye nokugcinwa rhoqo kunokuphucula ukusebenza kunye nokuqina.

3. Izakhono zokusebenza eziphambili

Ulawulo lobushushu

Insimbi engenasici ine-thermal conductivity engalunganga kwaye ilukhuni ngokulula okanye ikhubazekile ngenxa yobushushu obuphezulu. Sebenzisa into yokupholisa (efana ne-oyile yokusika) okanye indlela yesondlo esongezelekayo ukunciphisa ubushushu bokunciphisa nokwandisa ubomi besixhobo.

Kuphephe ukusika ngokuqhubekayo ngesantya esiphezulu kwaye unqumame ukulahla ubushushu ngamaxesha afanelekileyo ukuthintela ukufudumeza kwendawo.

Isixhobo kunye nokulungiswa kweparameter

Isixhobo sezixhobo: I-Carbide okanye i-cobalt-equkethe izixhobo zetsimbi ze-speed-speed zikhethwa ukuba zikhuseleke kangcono.

Ukusika iiparamitha: Isantya esiphantsi kunye ne-torque ephezulu (efana naxa kusomba), kunye nezinto zokuthambisa ukuphucula umphezulu wokugqiba.

Imowudi yokutyisa: Ukutya okongeziweyo (ukusika okungaqhubekiyo) kunokunciphisa ukuqokelelwa kobushushu kunye nokunciphisa ubushushu ngaphezu kwe-30% xa kuthelekiswa nokutya kwe-radial.

Unyango olulandelayo

Deburring: Polish ukusika ngefayile, i-sandpaper okanye i-angle grinder ukuqinisekisa ukhuseleko kunye nobuhle.

Ukucocwa kwepickling: Ukuba ufuna ukususa isikali se-oxide, sebenzisa i-asidi edibeneyo (efana ne-HNO₃ + HF) yokukhetha, kodwa ixesha kufuneka lilawulwe ukuphepha ukubola okukhulu.

4. Iimpawu zezinto kunye neendlela zokulungelelanisa

Intsimbi ye-Austenitic (efana ne-304/316): i-ductility eyomeleleyo, kulula ukunamathela kwimela, ifuna isixhobo sokuqina okuphezulu kunye nokupholisa okwaneleyo.

I-molybdenum-equlethe intsimbi engatyiwayo (efana ne-316): Ukumelana ne-corrosion ephezulu, kodwa ukuxhathisa ukusika okuphezulu, kuyacetyiswa ukuba usebenzise isantya esiphantsi kunye ne-lubricity high coolant.

Uhlobo olulula ukusika (njenge 303): iqulethe i-sulfure okanye i-selenium elements, enokunyusa isantya sokusika, ukunciphisa ukugqoka izixhobo, kwaye ifanelekile ukuqhutyelwa kwesantya esiphezulu.

5. Ukhuseleko kunye nokugcinwa

Ukhuseleko lomntu: iiglavu, iiglavu ezisikiweyo, iimaski zothuli (ukuphepha ukuphefumla uthuli lwesinyithi).

Ukuhlolwa kwezixhobo: buyisela rhoqo iiblades ezigugileyo / amavili okugaya ukuqinisekisa ukusika ukusebenza kakuhle kunye nokhuseleko.

Ulawulo lokusingqongileyo: gcina umoya, hlala kude nezinto ezinokutsha, kwaye ucoce inkunkuma yesinyithi ngexesha.

Isishwankathelo: Ukusika iipleyiti zensimbi ezingenasici zifuna ukuqwalaselwa ngokubanzi kobunzima, izinto eziphathekayo kunye neemeko zesixhobo, ngokuphambili kunikwe ukulawula ukushisa kunye nokugqoka izixhobo. Kwiimfuno ezichanekileyo ezichanekileyo, kuyacetyiswa ukuba ukhuphe i-laser / ijethi yokusika amanzi; kwimisebenzi yemihla ngemihla, izixhobo ze-carbide + i-coolant + isondlo esongezelelweyo zezona zisombululo zisebenzayo. Qinisekisa ukuba uqhelene neendlela zokusika ezibhityileyo, eziphakathi kunye nezingqindilili, kwaye ubeke ingqalelo kumlinganiselo ococekileyo, okhuselekileyo kunye nochanekileyo wokusika ukuze uqinisekise ukuba ukusikwa ngakunye akunasiphako.

Ixesha lokuposa: May-10-2025